A method for nanosecond laser irradiation to induce the formation of micro-nano multilayer structures on the surface of amorphous carbon

A multi-layer structure and laser irradiation technology, which is applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of high cost and low efficiency of femtosecond or picosecond laser processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

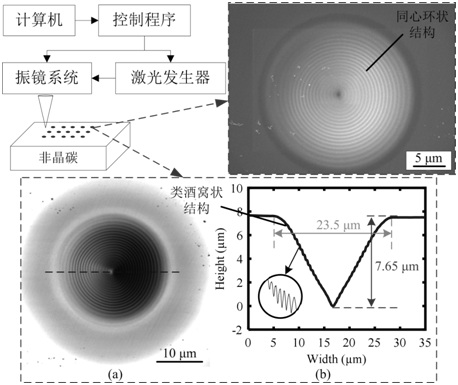

[0032] The method for nanosecond laser irradiation in this embodiment to induce the formation of a micro-nano multilayer structure on the surface of amorphous carbon, the specific steps are as follows:

[0033] Step 1: The amorphous carbon sample with a diameter of 40 mm and a thickness of 10 mm is firstly polished, ultrasonically cleaned with absolute ethanol, and dried to obtain a pretreated amorphous carbon sample. The cleaning temperature is 50°C, and the single cleaning time is 5 minutes.

[0034] Step 2. The laser light generated by the nanosecond fiber laser is converted and focused by the galvanometer system, and then vertically incident on the surface of the amorphous carbon sample obtained in step 1; by controlling the irradiation time and energy density of the nanosecond laser pulse, using The material removal effect of laser and the interference effect of light are used to prepare micro-nano multi-layer structure on the surface of amorphous carbon. The laser proce...

Embodiment 2

[0038] The method for nanosecond laser irradiation in this embodiment to induce the formation of a micro-nano multilayer structure on the surface of amorphous carbon, the specific steps are as follows:

[0039] Step 1: The amorphous carbon sample with a diameter of 40 mm and a thickness of 10 mm is firstly polished, ultrasonically cleaned with absolute ethanol, and dried to obtain a pretreated amorphous carbon sample. The cleaning temperature is 50°C, and the single cleaning time is 5 minutes.

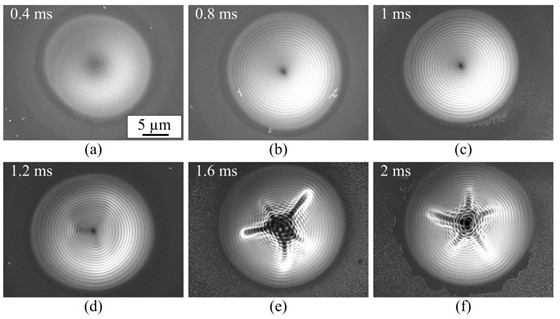

[0040] Step 2. The laser light generated by the nanosecond fiber laser is converted and focused by the galvanometer system, and then it is perpendicularly incident on the surface of the amorphous carbon sample obtained in step 1. By changing the laser processing parameters, a 5×5 multi-point array micro-nano multi-point array is prepared. layer structure. The laser processing parameters are as follows: the laser frequency is 700kHz, the pulse width is 7ns, the laser pulse duration is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com