Clamping and hoisting device

A hoisting plate and hoisting hole technology, used in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem that the torsional buckling deformation of box-shaped components is difficult to control, the levelness and verticality of box-shaped components cannot reach, Constraining the smooth implementation of construction progress and quality, and achieving the effects of safe construction, social and economic benefits, convenient and fast construction operations, and reduction of hidden structural safety problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

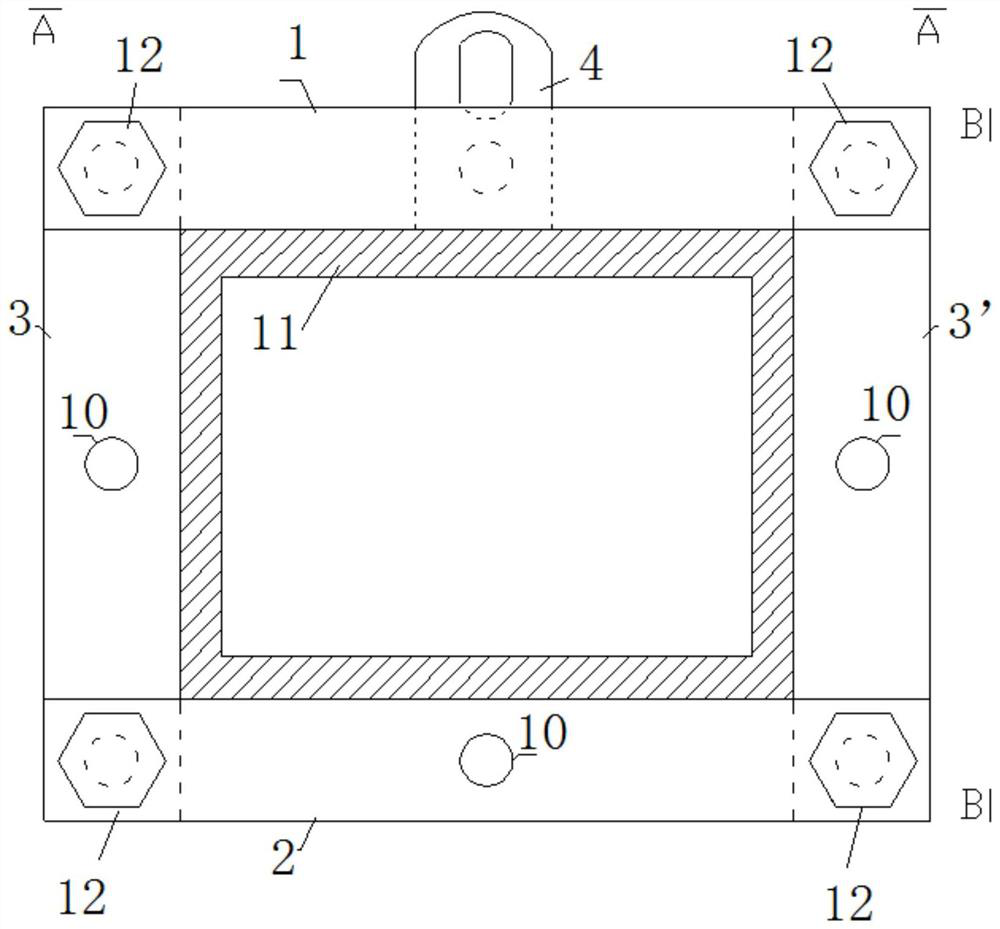

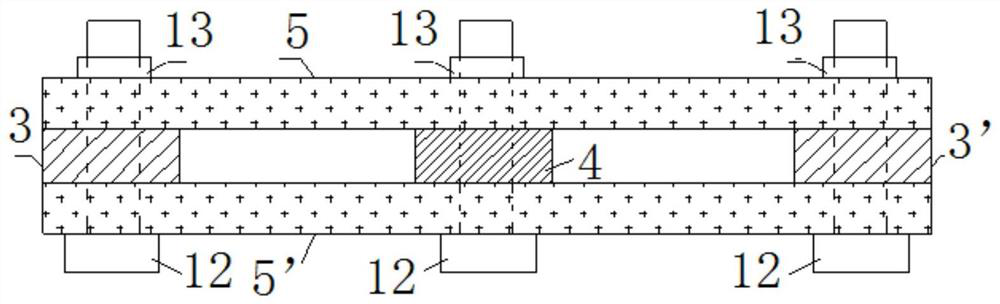

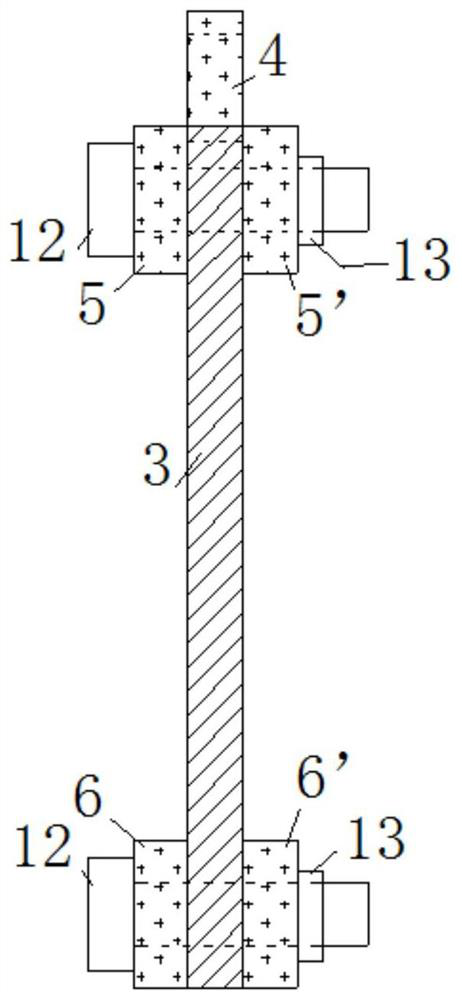

[0019] Such as Figure 1-4 As shown, a clamping and hanging device includes: an upper splint 1, a lower splint 2, two vertical splints 3, 3 ', and a lifting plate 4;

[0020] The upper clamping plate 1 has the same structure as the lower clamping plate 2. The upper clamping plate 1 comprises two horizontal rectangular plates 5, 5' arranged oppositely, and the lower clamping plate 2 comprises two horizontal rectangular plates 6, 6' arranged oppositely (such as image 3 As shown), the two ends of the upper splint 1 and the lower splint 2 are provided with corresponding bolt holes;

[0021] The two vertical splints are rectangular plates arranged vertically, the upper end of the vertical splint 3 is connected to one end of the upper splint 1, the lower end of the vertical splint 3 is connected to one end of the lower splint 2, and the upper end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com