Clamp with shock absorption function for precision machine tool

A technology of precision machine tools and utensils, used in clamping, manufacturing tools, metal processing mechanical parts, etc., can solve the problems of low production efficiency, low qualified rate of workpiece products, inconvenient machine tool processing, and product quality problems, and achieves a reduction in production efficiency. Small vibration, convenient control, and the effect of improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

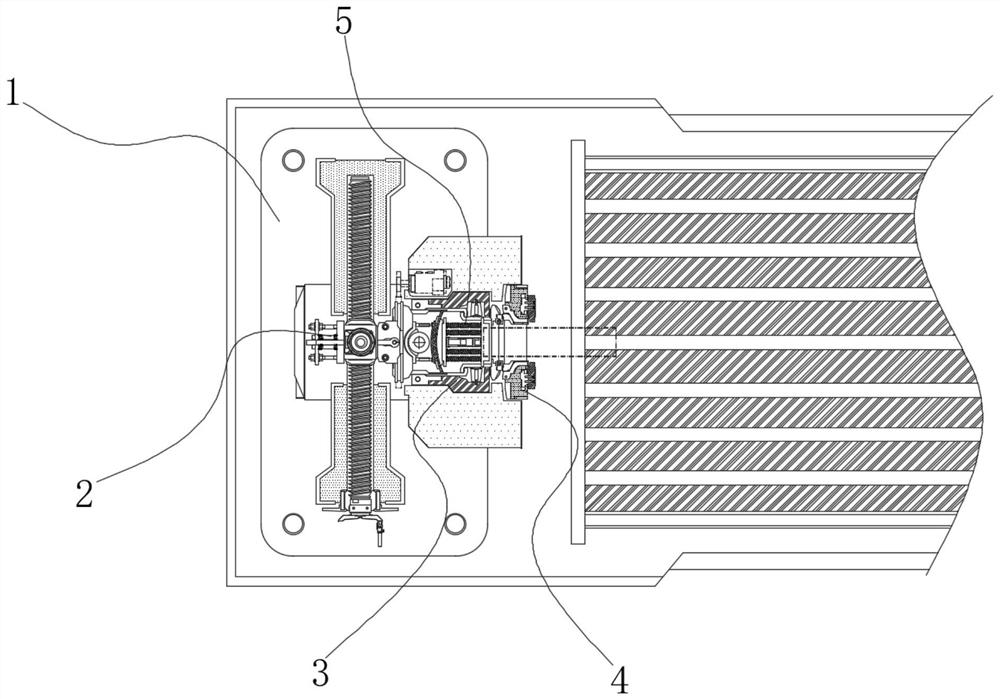

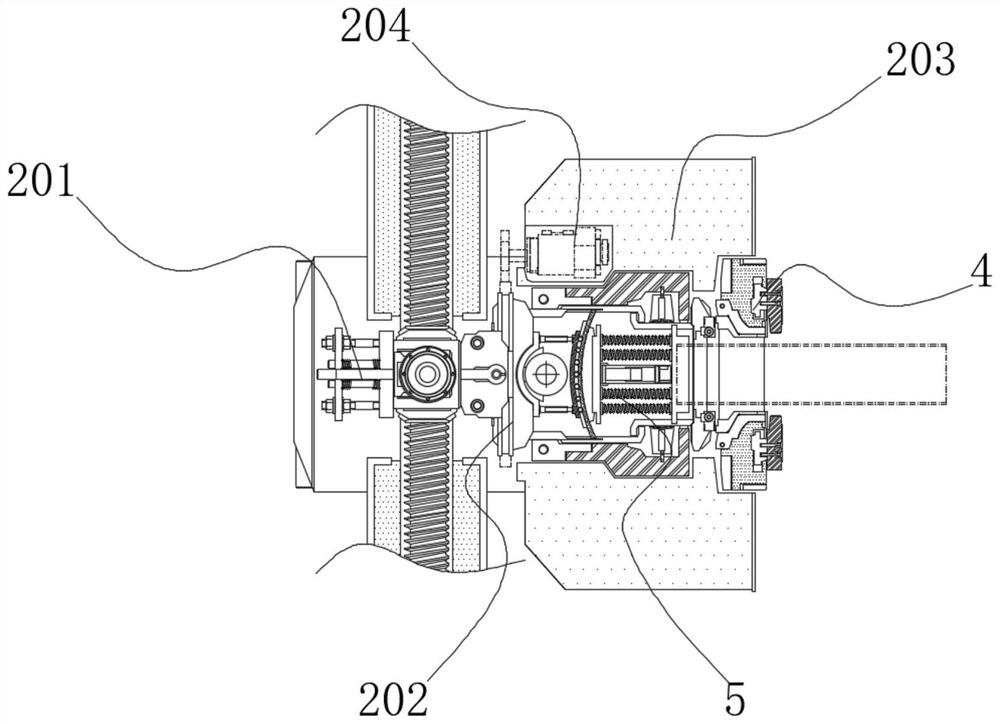

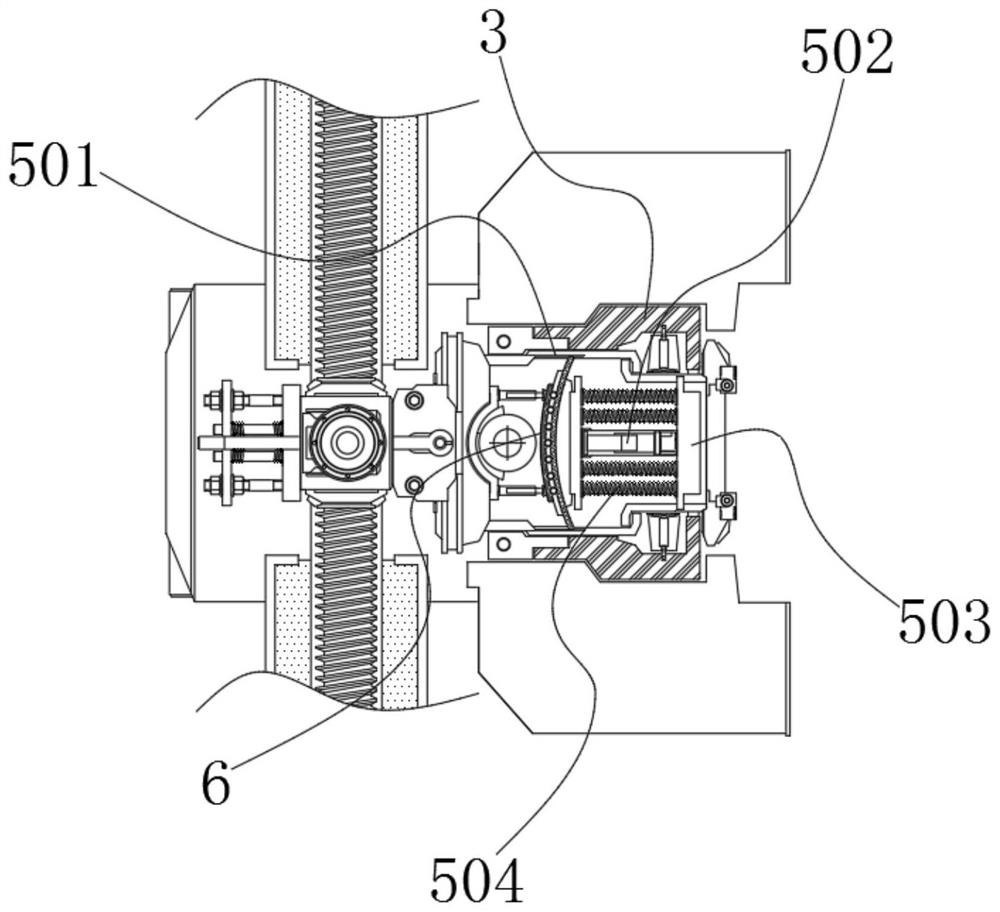

[0035] refer to figure 1 , the present invention provides a technical solution: a jig with a shock-absorbing function for a precision machine tool, which includes a fixed base 1, a support base 2, a mechanical jaw plate 4, a phase buffer assembly 5, and a sliding limit assembly 3, wherein the The fixed base 1 is fixed on one side of the upper end surface of the machine tool workbench by bolts, and a support base 2 is installed above the fixed base 1. It is characterized in that: a mechanical claw plate 4 is installed in the horizontal direction of the support base 2, so that The mechanical claw plate 4 is clamped and fixed at one end of the workpiece to be processed;

[0036] A phase buffer assembly 5 is also arranged between the support base 2 and the mechanical claw plate 4, and the phase buffer assembly 5 slows down the vibration received by the mechanical claw plate 4 as a whole, so that the workpiece to be processed is transmitted to the mechanical claw plate during proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com