White asparagus tail cut-away device

A technology of asparagus, side part, applied in the field of white asparagus tail cutting device, to achieve the effect of reducing manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A device for removing tails of white asparagus, such as figure 1 As shown, it includes a base plate 1, a first mounting plate 2, a fixing plate 3, a lifting mechanism 4, a placement mechanism 5 and a cutting mechanism 6. The left and right sides of the base plate 1 are provided with the first mounting plate 2, and the first mounting plate 2 on both sides is provided. A fixed plate 3 is connected between the upper parts of the plates 2, a lifting mechanism 4 is arranged on the first mounting plates 2 on both sides, a placement mechanism 5 is arranged between the first mounting plates 2 on both sides, and the placement mechanism 5 is connected with the lifting mechanism 4 , A cutting mechanism 6 is provided between the top of the fixing plate 3 and the first mounting plates 2 on both sides.

[0038] When it is necessary to cut off the white asparagus tail, manually move the parts of the placement mechanism 5 upwards, move the parts of the placement mechanism 5 backwards, ...

Embodiment 2

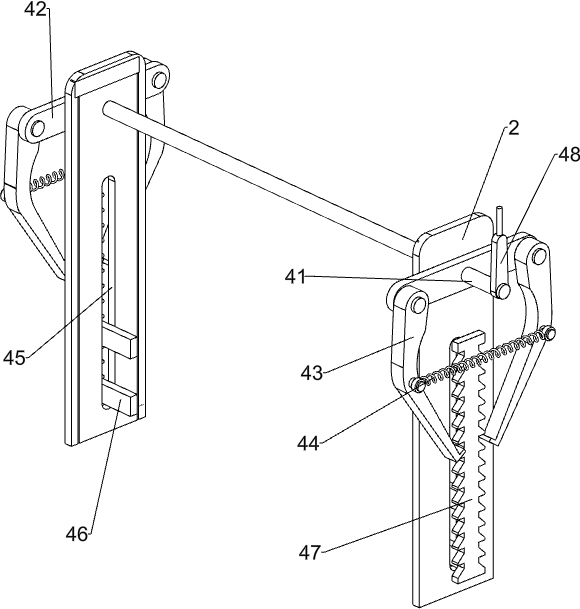

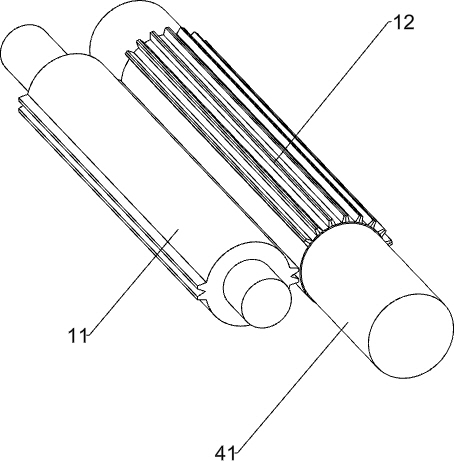

[0040] according to Figure 2-3 As shown, the lifting mechanism 4 includes a first rotating shaft 41, a swing plate 42, a pawl 43, a first elastic member 44, a slider 46, a ratchet bar 47 and a handle 48, and the first mounting plate 2 tops on both sides are rotated. A first rotating shaft 41 is provided, and a swing plate 42 is installed on the left and right sides of the first rotating shaft 41. The front and rear sides of the swing plate 42 are rotatably provided with ratchets 43, and the middle parts of the two ratchets 43 on the same side are connected with The first elastic member 44 has a chute 45 on the first mounting plate 2 on both sides, and two sliders 46 are slidably installed in the chute 45, and the side of the slider 46 near the ratchet 43 is connected. A ratchet bar 47 is arranged, and a handle 48 is installed at the right end of the first rotating shaft 41 .

[0041] After the white asparagus is placed, start the parts of the cutting mechanism 6 manually, th...

Embodiment 3

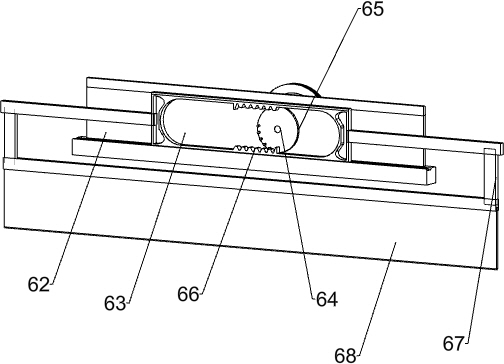

[0045] Specifically, such as Figure 4-8 As shown, the cutting mechanism 6 includes a second mounting plate 61, a first slide rail 62, a circular frame 63, a second rotating shaft 64, a chuck 65, a spur rack 66, a mounting frame 67, a cutting knife 68, a first bearing seat 69. The third rotating shaft 610, the bevel gear 611, the motor 612 and the first belt drive assembly 613, the second mounting plate 61 is arranged between the upper front side of the first mounting plate 2 on both sides, and the bottom of the second mounting plate 61 is provided with The first slide rail 62, the middle part of the first slide rail 62 is slidably equipped with a return-shaped frame 63, and the second slide rail 7 is provided with a second rotating shaft 64 in a left-hand rotation type, and the rear side of the second rotating shaft 64 is connected with a chuck 65. Shaped frame 63 middle part is equipped with spur rack 66 up and down both sides, and spur rack 66 cooperates with chuck 65, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com