Concrete mixer with power saving function

A concrete mixer and functional technology, applied in the field of new energy-saving equipment, can solve problems such as energy waste and mixing resistance, and achieve the effects of reducing consumption, reducing resistance and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

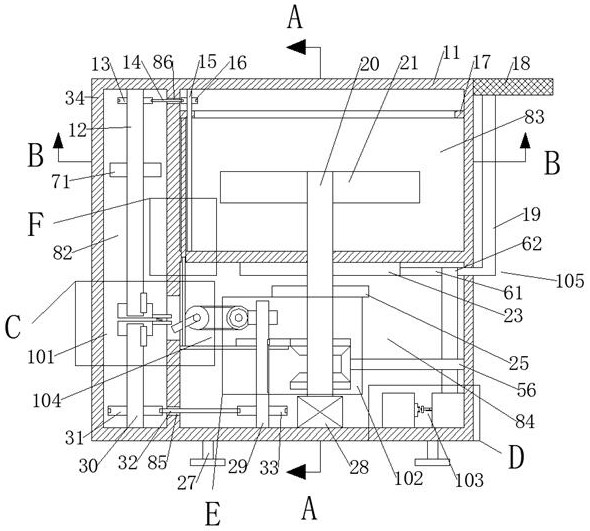

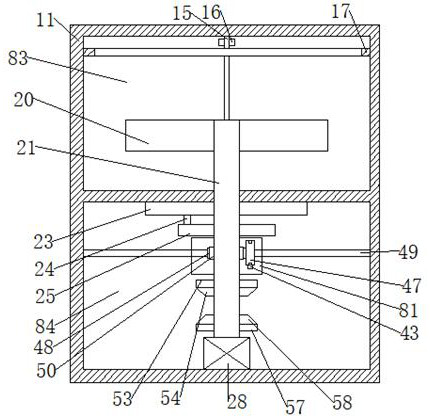

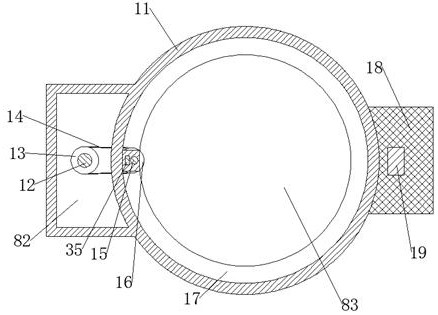

[0020] Combine below Figure 1-Figure 7 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0021] A concrete mixer with power-saving function according to the present invention comprises a main box body 11, a mixing chamber 83 is arranged inside the main box body 11, and an upper belt opening facing left is provided at the upper end of the left wall of the mixing chamber 83. Wheel chamber 86, the left end of the lower wall of the stirring chamber 83 is provided with a slide chamber 87 opening to the left, the lower end of the stirring chamber 83 is connected with the power chamber 84 through the slide chamber 87, and the lower end of the left wall of the power chamber 84 is provided with There is a lower pulley chamber 85 with an opening to the left. The left side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com