FDM(Fused Deposition Modeling) printer planar electrode type automatic leveling device

A planar electrode and automatic leveling technology, applied in the field of additive manufacturing, can solve problems such as low efficiency, laborious leveling process, and inability to guarantee leveling accuracy, so as to achieve the effect of improving efficiency and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

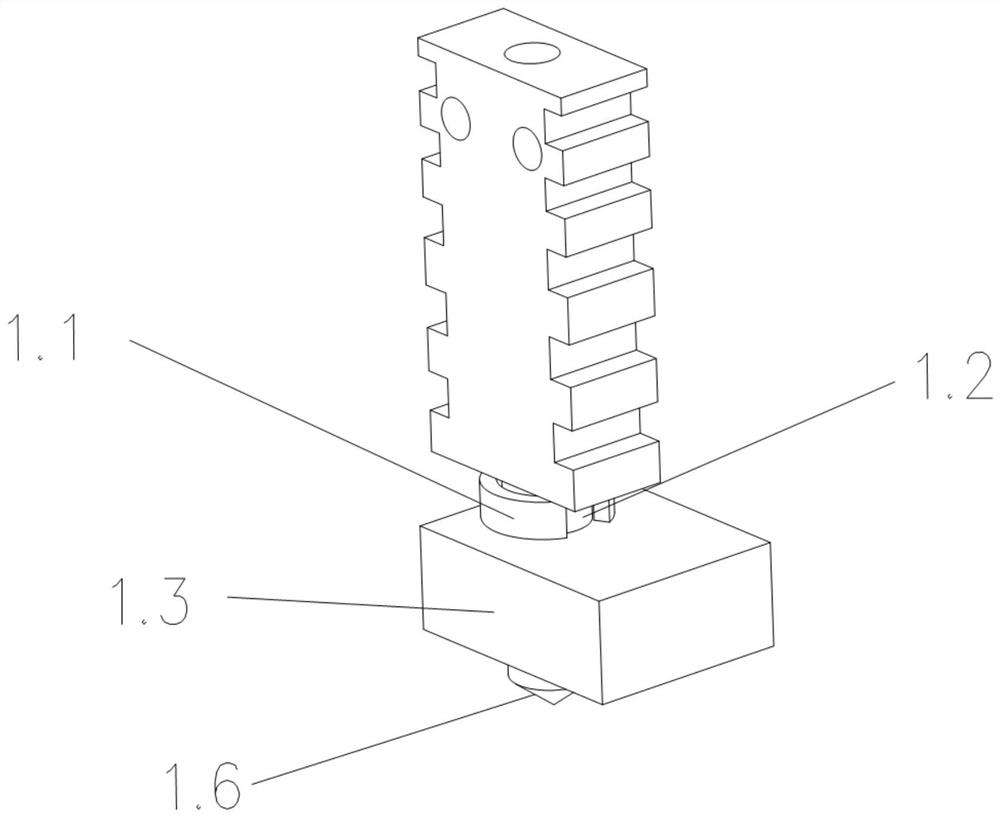

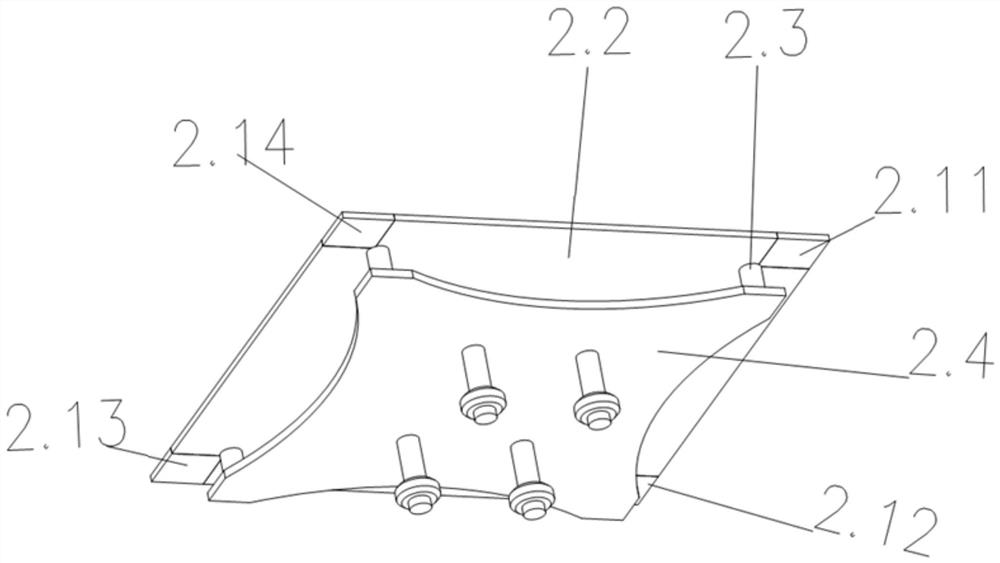

Method used

Image

Examples

Embodiment

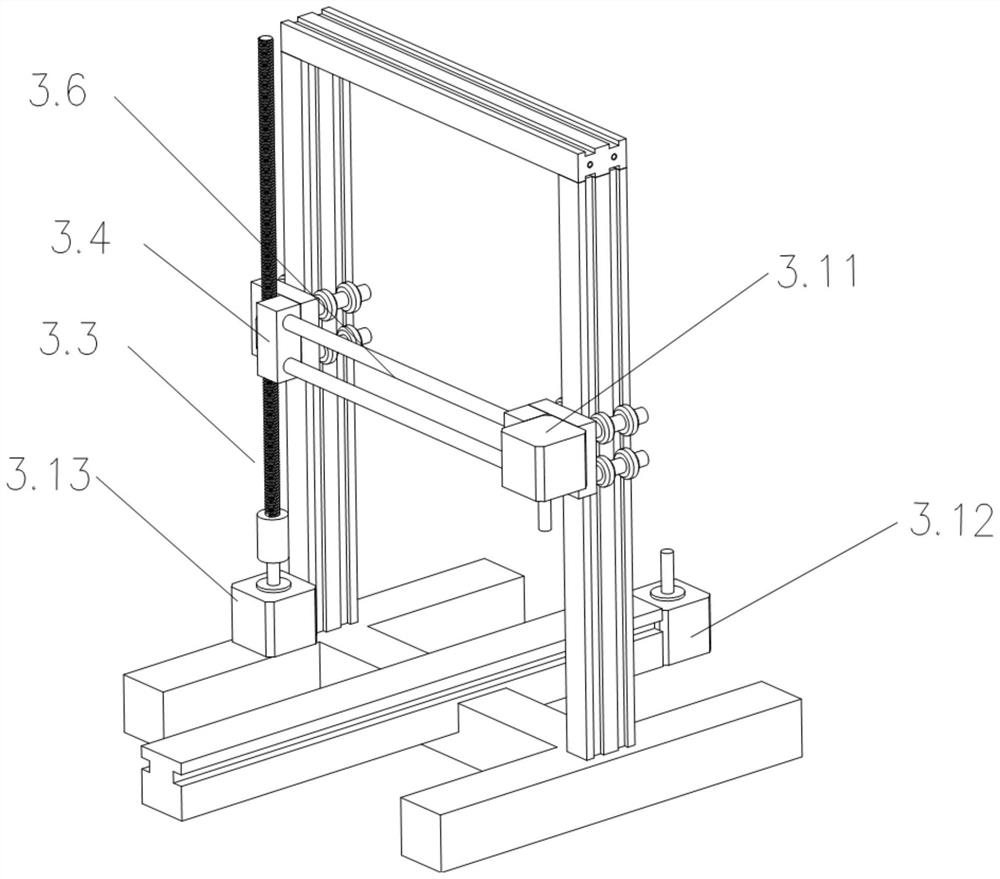

[0028] Example: The leveling process is as follows:

[0029] 1. The X-axis and Y-axis stepping motors 3.11 and 3.12 in the transmission module 3 drive the FDM nozzle module 1 to move in the negative direction of the X direction through the transmission belt, and the printing platform module 2 moves in the negative direction of the Y-axis direction. Move in the direction until the limit switch is touched, and the printing coordinates of the X-axis and Y-axis are reset to zero. The printer control mainboard 3.5 recognizes the limit switch signal, sends a signal to stop the stepper motor from rotating, records the current X-axis position and Y-axis position in the mainboard memory, and sets this as the starting point of the printing coordinates X direction and Y direction.

[0030] 2. The Z-axis stepping motor 3.13 rotates in reverse, driving the screw rod 3.3 to rotate, so that the X-axis pulley platform 3.6 moves in the negative direction of the Z direction until the tip of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com