Novel metallurgical embedded scraper transporter special tail device

A buried scraper conveyor and a new type of technology, applied in the field of special tail devices for new metallurgical buried scraper conveyors, can solve the problems of equipment operation obstruction, tail accumulation, irregular shape, etc., and achieve easy popularization, efficiency improvement, manufacturing low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

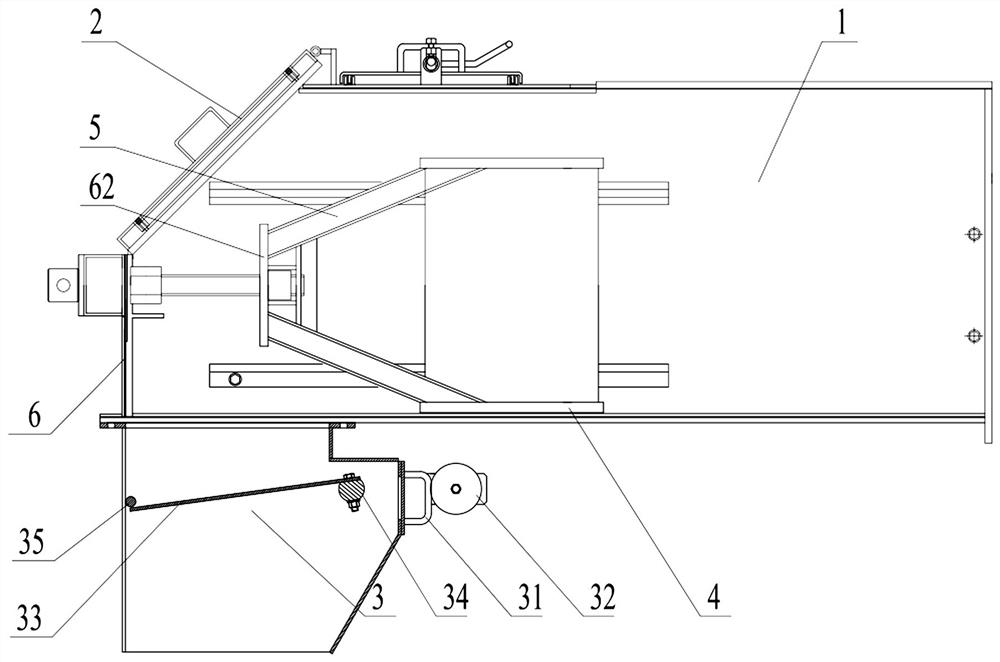

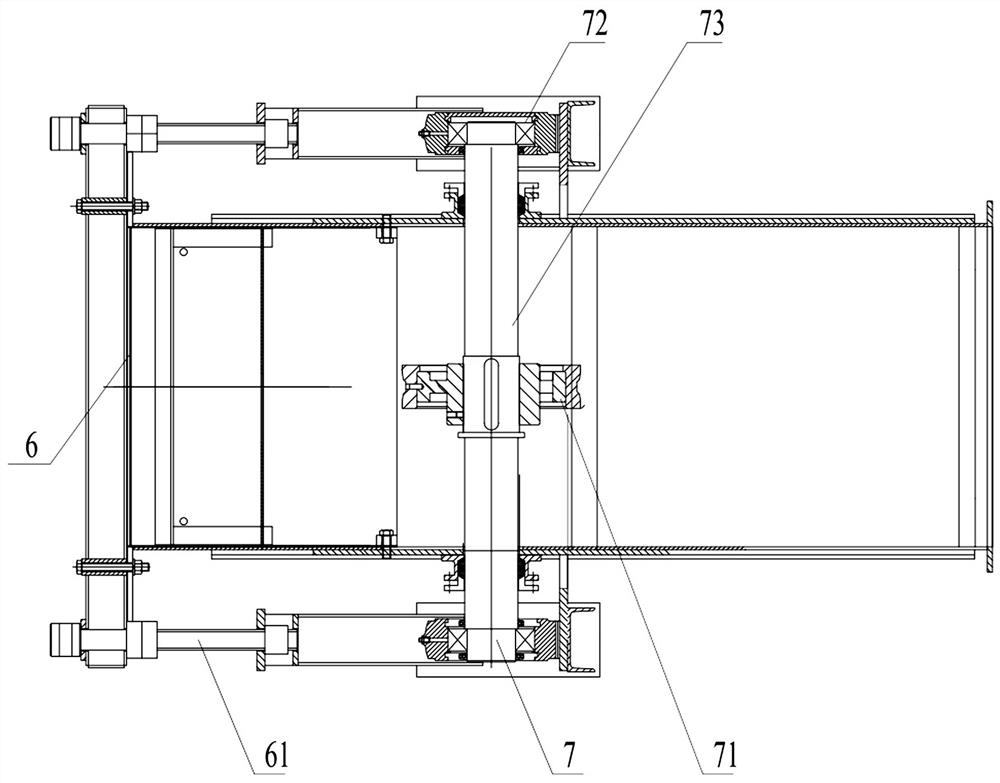

[0019] like Figure 1~2 As shown, a new special tail device for metallurgical buried scraper conveyor includes a casing 1 and a transmission mechanism 7, the casing 1 includes a heavy hammer door 2, and the heavy hammer door 2 is located on the upper part of the casing 1, so The casing 1 is provided with a slide plate 4 along the moving direction of the conveyor scraper, and the lower part of the casing 1 is fixed with a gravity flap mechanism 3 . With this structure, after the tail of the conveyor is completed, the heavy hammer door 2 can be manually opened to complete the unloading, or the sliding slide 4 can be used to complete the unloading on the side of the conveyor. The unloading process at the bottom of the machine.

[0020] In a preferred solution, one end of the heavy hammer door 2 is connected to the housing 1 through a hinge, and a door handle is provided on the heavy hammer door 2 . With this structure, large materials can complete the material unloading process...

Embodiment 2

[0030] Further illustrate according to embodiment 1, as Figure 1~2 Shown:

[0031] The material falls from the head of the metallurgical buried scraper conveyor into the interior of the shell 1, and is transported to the tail under the operation of the transmission mechanism 7. Due to the heavy weight and irregular shape of the metallurgical material, it is easy to form the accumulation and accumulation of the tail material. Congestion, by setting the mass of the counterweight 32 on the gravity turnover mechanism 3, when a part of the material with a small volume accumulates to exceed the weight of the turnover action as a whole, the material will push the turnover panel 33 to open under the action of gravity, and this will be automatically completed. When some materials are unloaded and other parts with larger volume are piled up, the rear baffle 6 can be pulled. At this time, the partition moves in the direction of the rear baffle 6. During the operation, openings are forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com