Plastic drum stacking machine and stacking method

A plastic bucket and stacking technology, applied in the field of stacking machines for stacking objects, can solve problems such as low production efficiency, loose stacking, and narrow application range, and achieve the goals of improving stacking efficiency, expanding application range, and improving accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

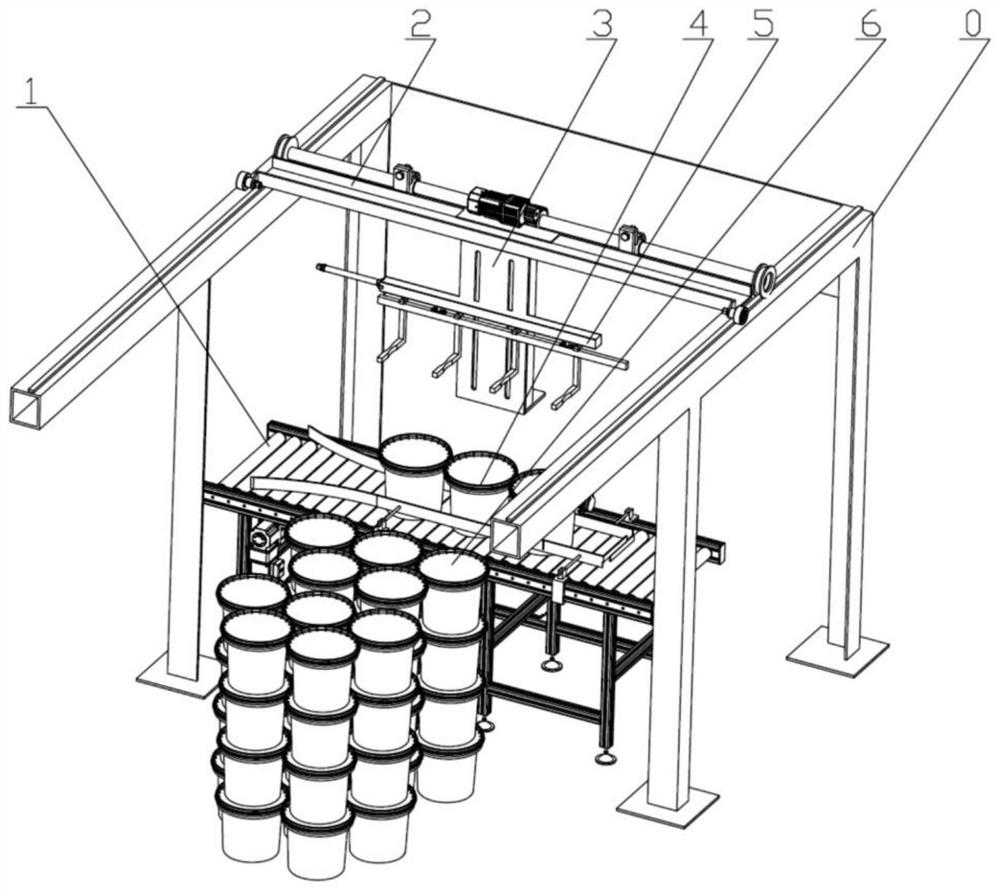

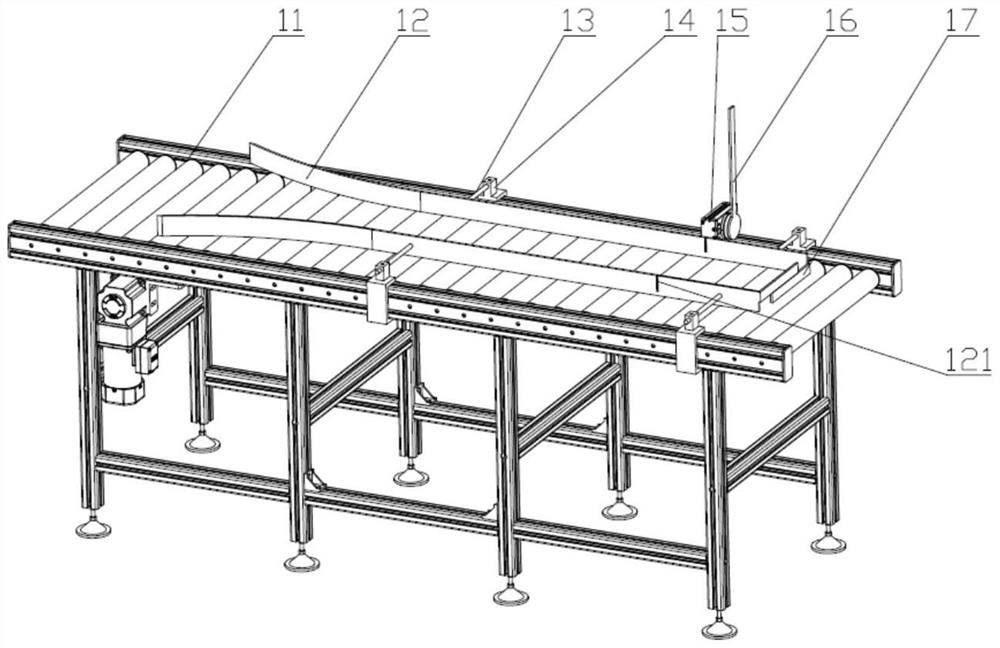

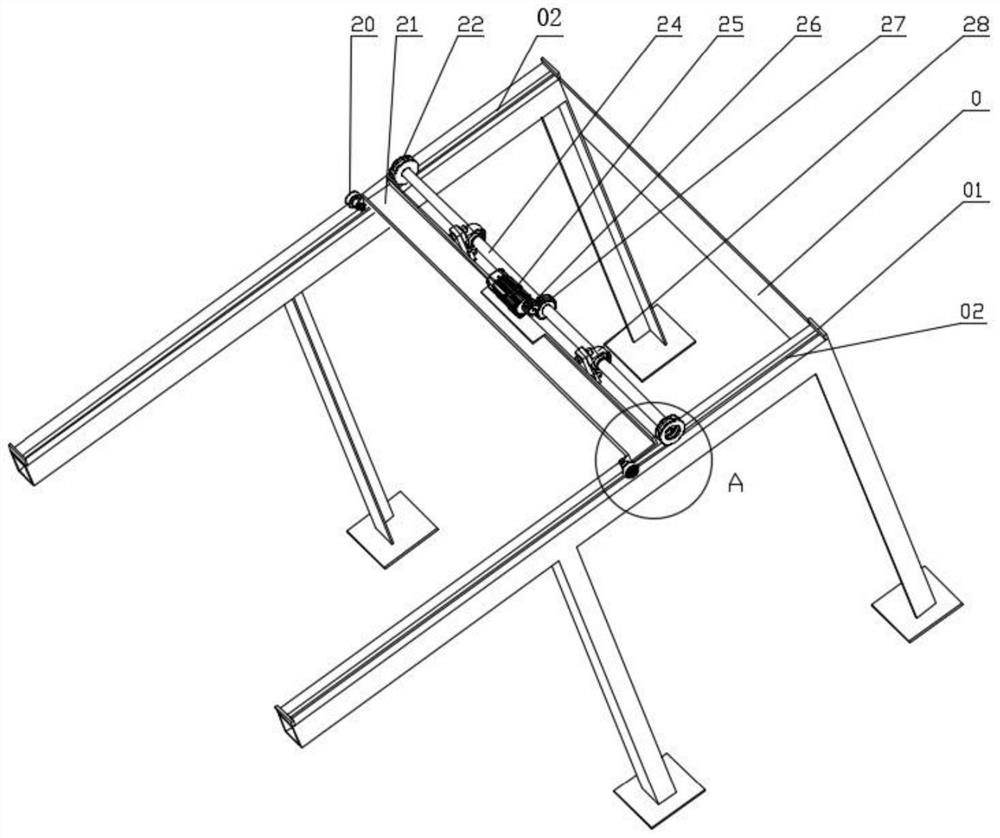

[0049] Such as figure 1 , figure 2 and image 3 As shown, a plastic barrel stacking machine includes a support frame 0, an assembly line part 1, a horizontal moving part 2, a vertical moving part 3, a plastic barrel 4 and an actuator part 5, and the top of the supporting frame 0 is provided with double Arms, the top surface of the arms of the support frame 0 is equipped with guide rails 02, the horizontal moving part 2 straddles the two guide rails 02 and can move along the guide rails 02; the top of the vertical moving part 3 Fixedly installed on the bottom surface of the horizontal moving part 2, the vertical moving part 3 is provided with a chute 331 along the vertical direction, the vertical driving part 3 is equipped with a vertical driving plate 37, and the vertical driving plate 37 can move along the vertical direction. The chute 331 moves; the actuator part 5 includes a cylinder 51, an actuator mounting bracket 52 and a gripper assembly 53, the actuator mounting bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com