Method for improving foam cell retraction behavior of thermoplastic elastomer microcellular foam material

A technology for thermoplastic elastomers and microcellular foaming materials, which is applied in the field of improving the shrinkage behavior of thermoplastic elastomers such as thermoplastic polyurethane microcellular foaming materials. To achieve the effect of maintaining shock absorption and rebound performance, convenient test method, and increased cell density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0036] Experimental raw materials: polyether TPU, brand: DESMOPAN DP.9385AU DPS650; hardness value 86A; provided by Covestro Polymers (China) Co., Ltd.; organically modified nano-montmorillonite (O-MMT), brand: I.44P, modified by dioctadecyl dimethyl ammonium bromide, provided by NANOCOR Co., Ltd. of the United States; CO 2 The gas, with a purity of 99.5%, was provided by Linde Gas (Chengdu) Co., Ltd.

[0037] Sample preparation process:

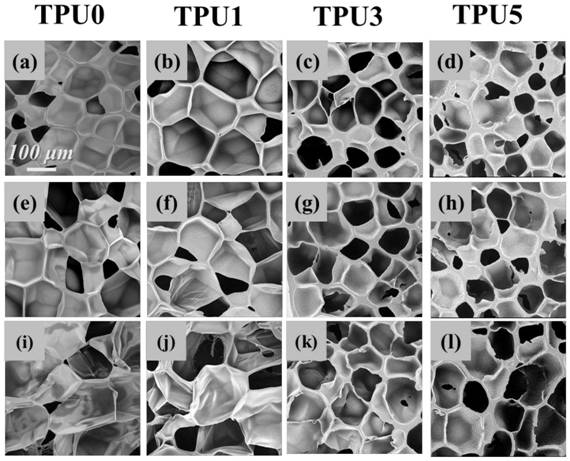

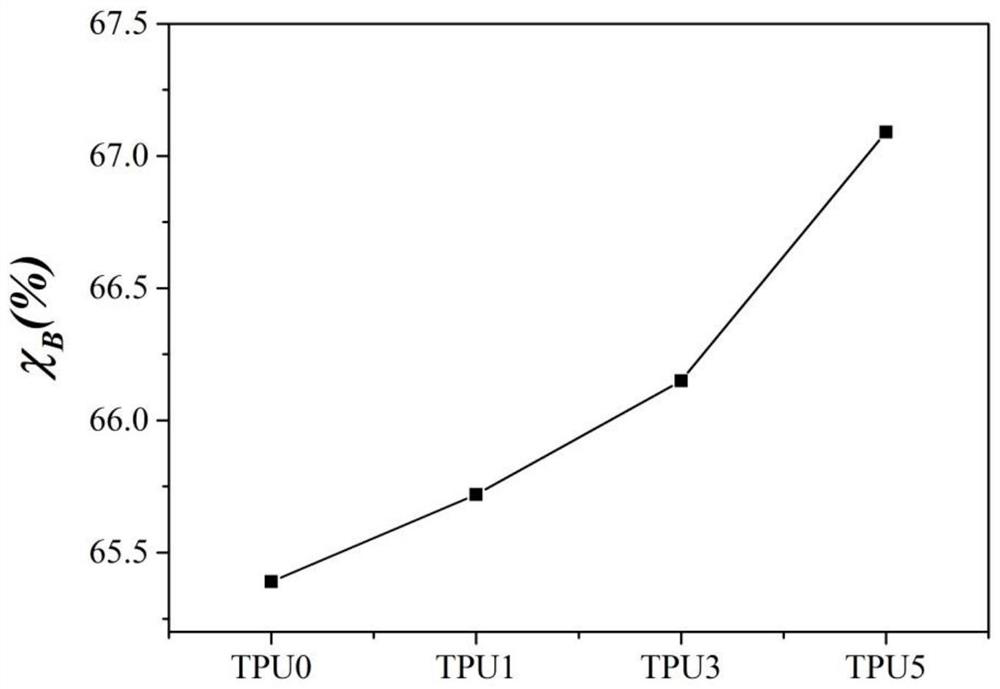

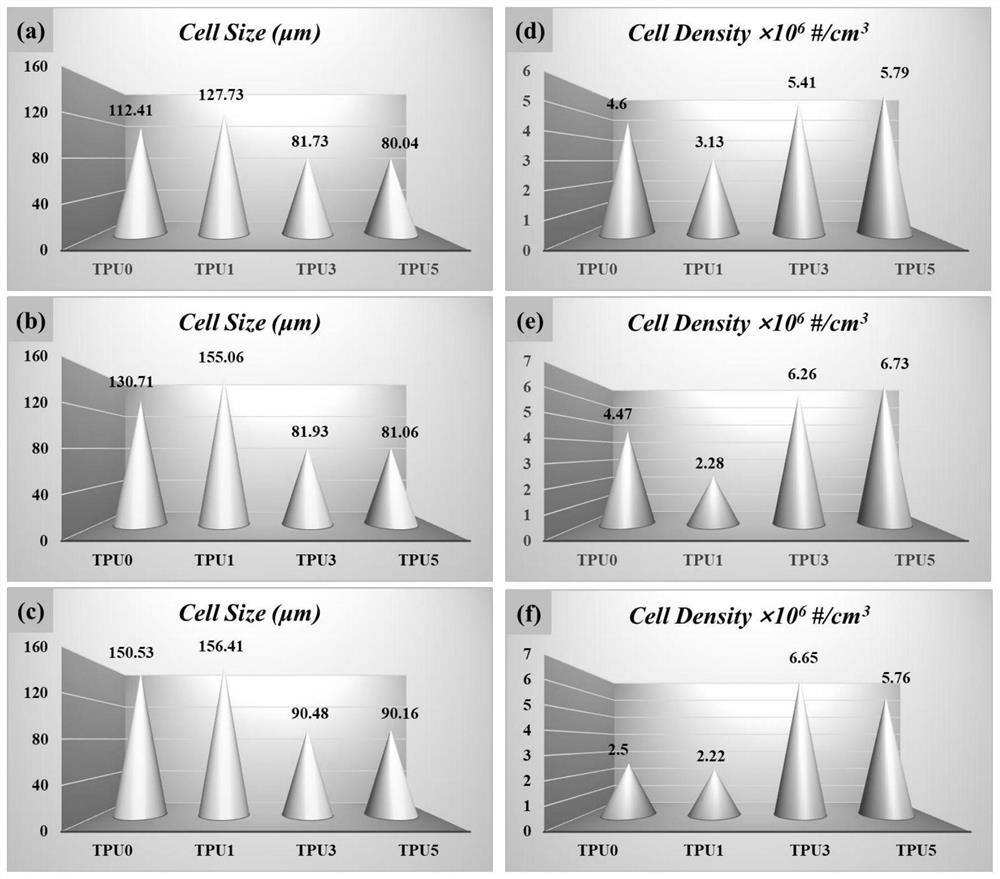

[0038] First, to remove the influence of moisture, place TPU and O-MMT in a vacuum oven at 80°C for 8 hours to vacuum dry; then, use a twin-screw extruder (machine model: NOE 02213, Nanjing Coperion Technology Co., Ltd. ) extruding the O-MMT masterbatch with a mass fraction of O-MMT of 10wt%, the temperature of the second to tenth sections of the extruder is 175°C, 180°C, 183°C, 185°C, 188°C, 190°C, 193°C, 195°C and 195°C were set sequentially; the die temperature was set to 195°C, and the twin-screw speed was set to 85rpm; then, the mass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com