Fermentation tank used for sauce processing

A fermenter and sauce technology, applied in the field of fermenter, can solve problems such as uneven mixing of sauce, incomplete fermentation, lack of stirring components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

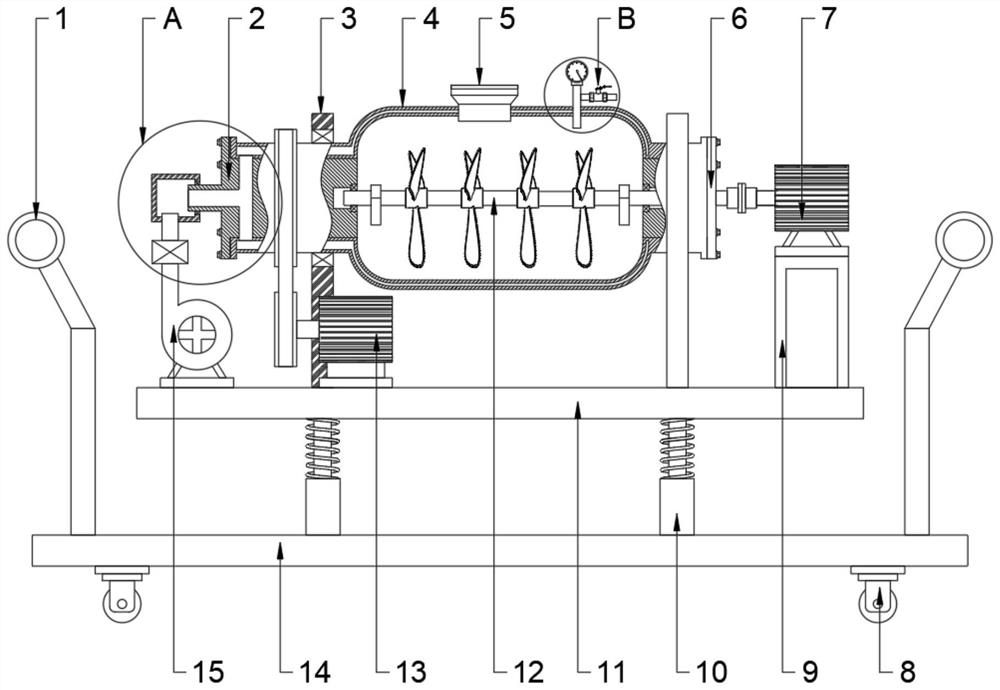

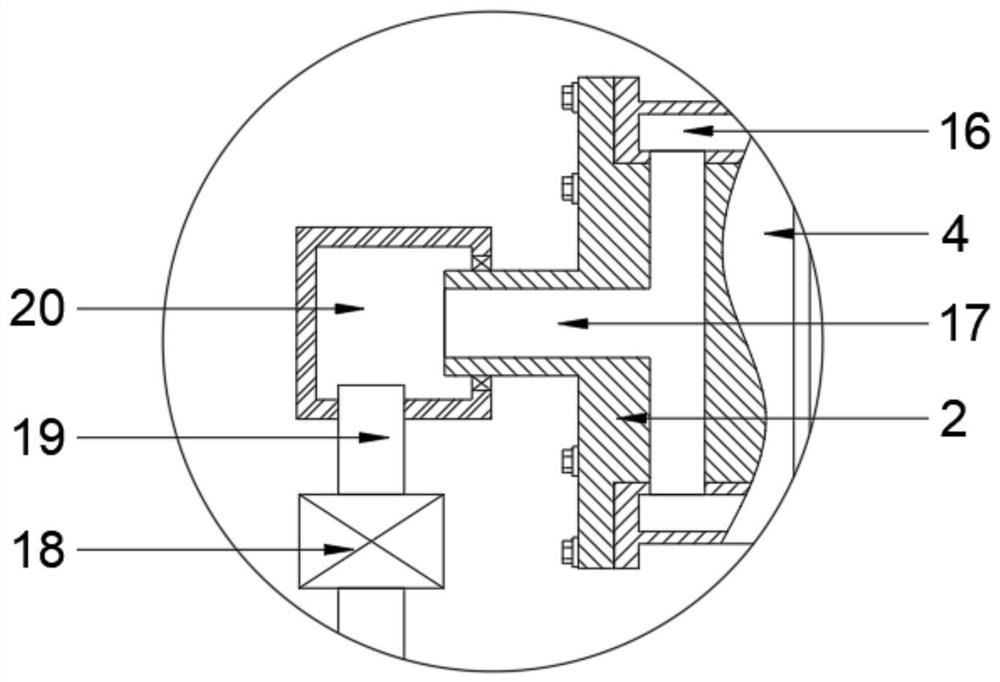

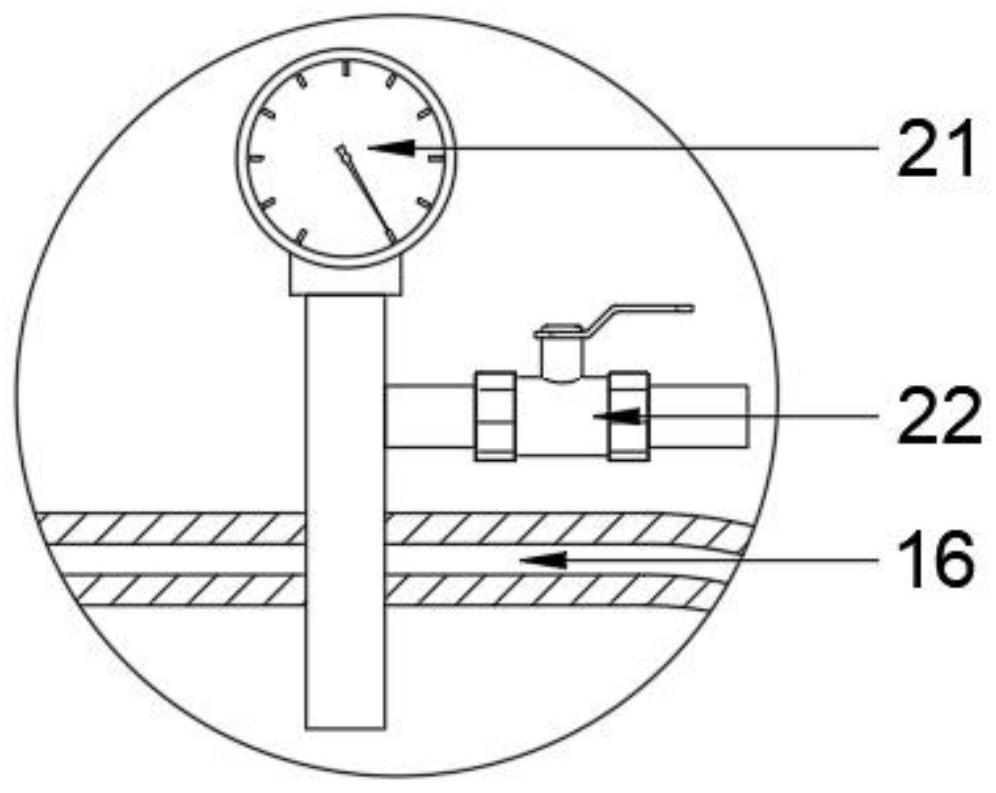

[0025] see Figure 1~5 , in an embodiment of the present invention, a fermenter for sauce processing, including a frame and a fermenter main body 4 mounted on the frame, the two ends of the fermenter main body 4 are respectively equipped with a left end cover 2 through bolts and sealing washers And the right end cover 6, the inside of the fermenter main body 4 is installed with a stirring assembly, the stirring assembly includes a stirring shaft 12, a stirring blade 26 and a stirring motor 7, and the two ends of the stirring shaft 12 are respectively installed on the left end cover by bearing rotation 2 and the right end cover 6 and its end near the right end cover 6 extends to the outside of the fermenter main body 4 and is set in linkage with the stirring motor 7 fixedly installed on the frame. The stirring motor 7 drives the stirring blade 26 to rotate through the stirring shaft 12, Make the sauce inside the main body 4 of the fermenter fully contact, mix evenly, and facili...

Embodiment 2

[0034] see figure 1 , 4 , in the embodiment of the present invention, a fermentation tank for sauce processing, in order to enhance the flexibility of the device, on the basis of embodiment 1, a roller 8 and a support rod 1 are added, and the top of the installation base 14 is provided with two A set of support rods 1 and four sets of rollers 8 are arranged at the bottom thereof. When the device needs to be transferred, push the support rod 1 to transfer the device through the rollers 8. The rollers 8 are also provided with a locking device. When the device is working, The roller 8 is fixed by a locking device to prevent shaking and keep stable.

[0035] The working principle of the present invention is:

[0036]When working, push the support rod 1, transfer the device to the required place through the roller 8 and fix the roller 8 through the locking device; open the inlet and outlet door, put the raw material of the sauce into the fermentation tank main body 4 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com