Intelligent bundling equipment for spinning

A kind of equipment and intelligent technology, which is applied in spinning machines, drafting equipment, textiles and papermaking, etc., can solve the problems of reduced effect of finished products, reduction of hairiness probability, easy entanglement of hemp strips, etc., and achieves the goal of improving work efficiency and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

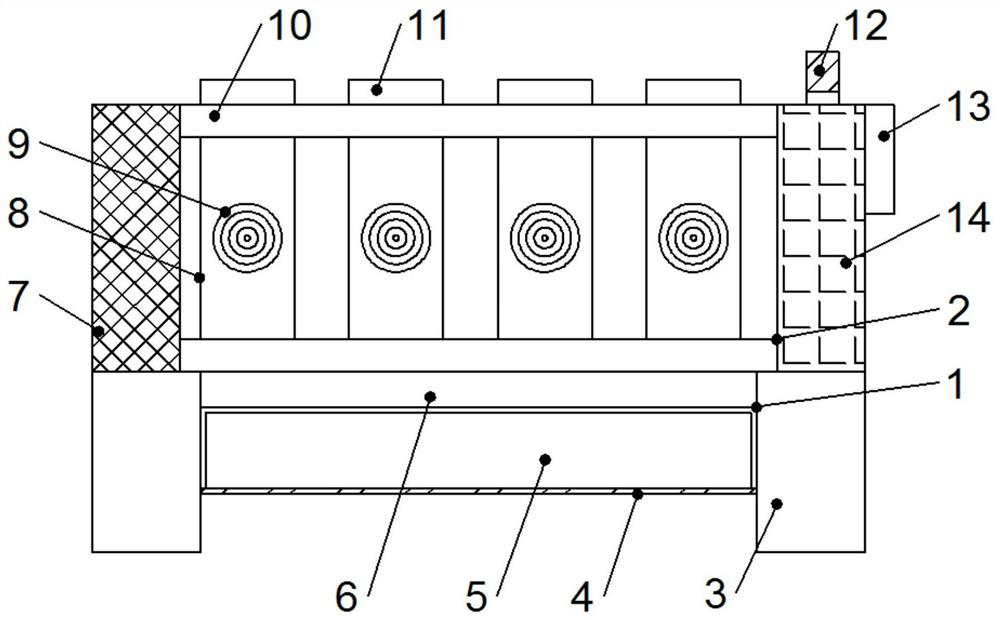

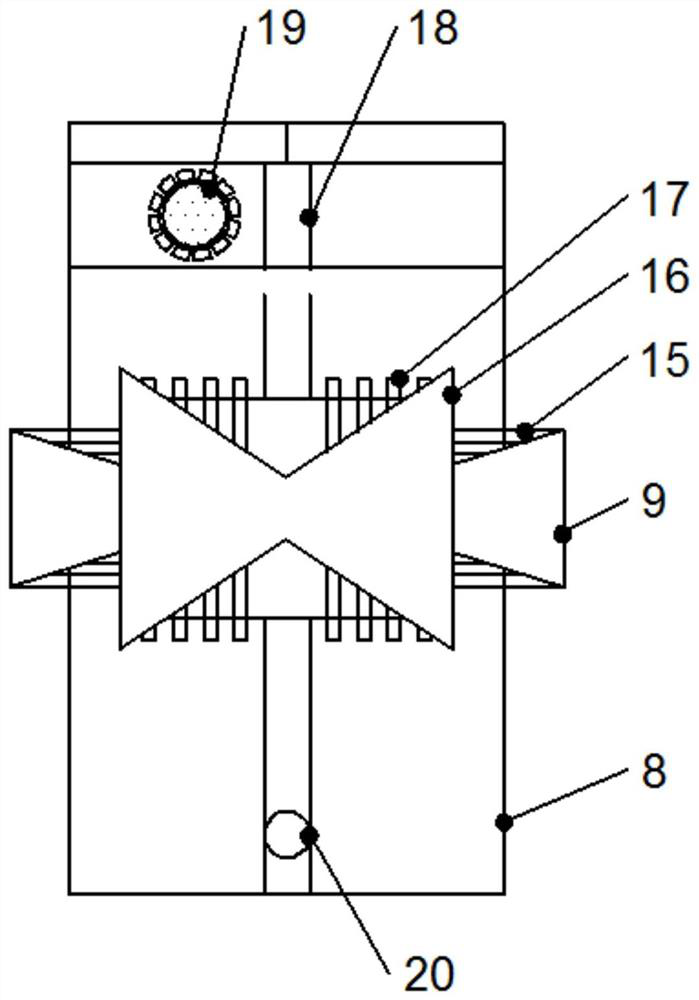

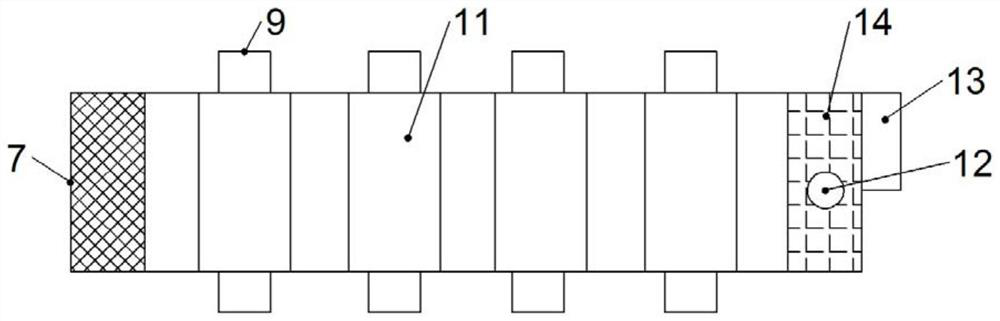

[0020] Example: such as Figure 1-3 As shown, an intelligent clustering device for spinning in the present invention includes a base 1, a backing plate 6 is arranged on the top of the base 1, columns 3 are arranged on both sides of the base 1, and a waste box 5 and a slide rail are arranged in the middle of the base 1 4. The top of the base 1 is provided with a main body 2;

[0021] Main body 2, one side of the main body 2 is provided with a vacuum motor 7, the central part of the main body 2 is equipped with a clustering device 8 and a clustering crossing 9, and the other side of the main body 2 is provided with a servo motor 14, and the surface of the servo motor 14 is provided with a touch screen Screen 13 and warning light 12, beam 10 is arranged on the top of main body 2, and top cover 11 is arranged on the top of main body 2.

[0022] Among them, the column 3 is provided with two groups installed on both sides of the base 1 and has a rectangular design, the backing plat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap