Complex site large rectangle pile stirrup pre-splicing construction method

A construction method and technology of rectangular piles, which are applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as the lack of entry conditions for large machines, large spacing between main reinforcements on both sides, and large dimensions of stirrups, etc., so as to avoid Difficulty in lengthening main reinforcement welding, reducing hoisting load, and reducing construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

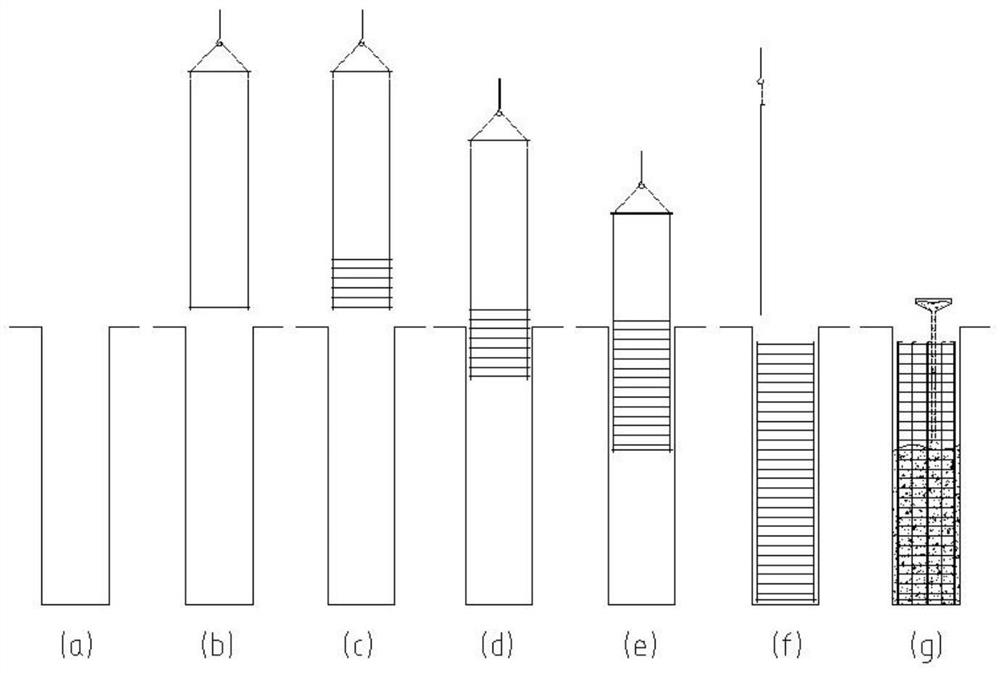

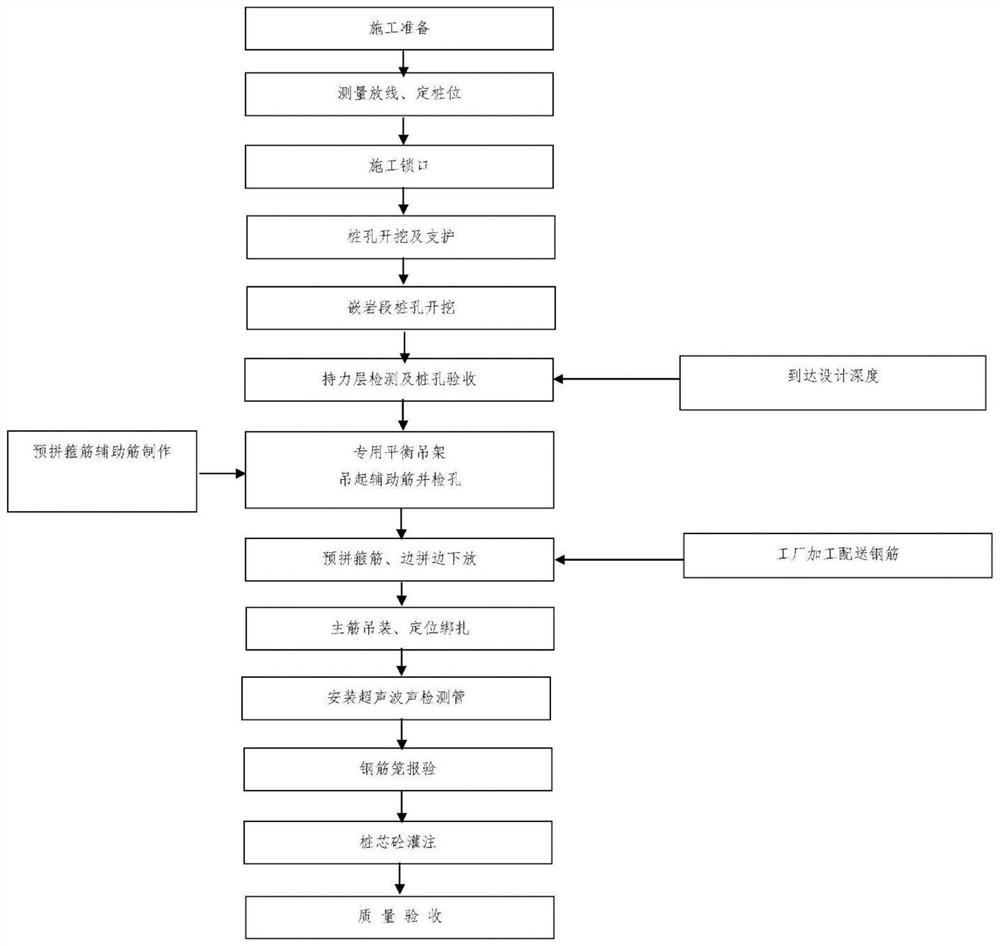

[0024] like figure 1 and figure 2 shown, including the following steps:

[0025] 1 Measuring setting-out and pile positioning

[0026] Setting out the pile position and elevation. According to the set axis control point and elevation benchmarking point, according to the pile location map, number the piles one by one, and release the pile location. Determine the center of the pile position and the direction of the axis, so as to determine the cross section of the pile and the outer line of the retaining wall. The lime sprinkling line is used as the boundary line of the pile hole excavation. After excavation.

[0027] 2 construction lock

[0028] 1. Set out the line according to the positioning, excavate the lock and a section of pile hole connected to the lock.

[0029] 2. After the pile hole of the first section is formed, tie the retaining wall and the locking reinforcement, and set up the formwork to pour the locking and retaining wall concrete. Two days after the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com