A prefabricated octagonal cable well

A technology of prefabricated assembly and cable well, which is applied in the directions of cable installation, cable installation in cable room, current collector, etc., can solve the problems that the cable well has no warning function, the cast iron cover is easily damaged, and the impact force is large. Achieve the effect of meeting large-scale and urgent construction needs, shortening the installation period, and avoiding smashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

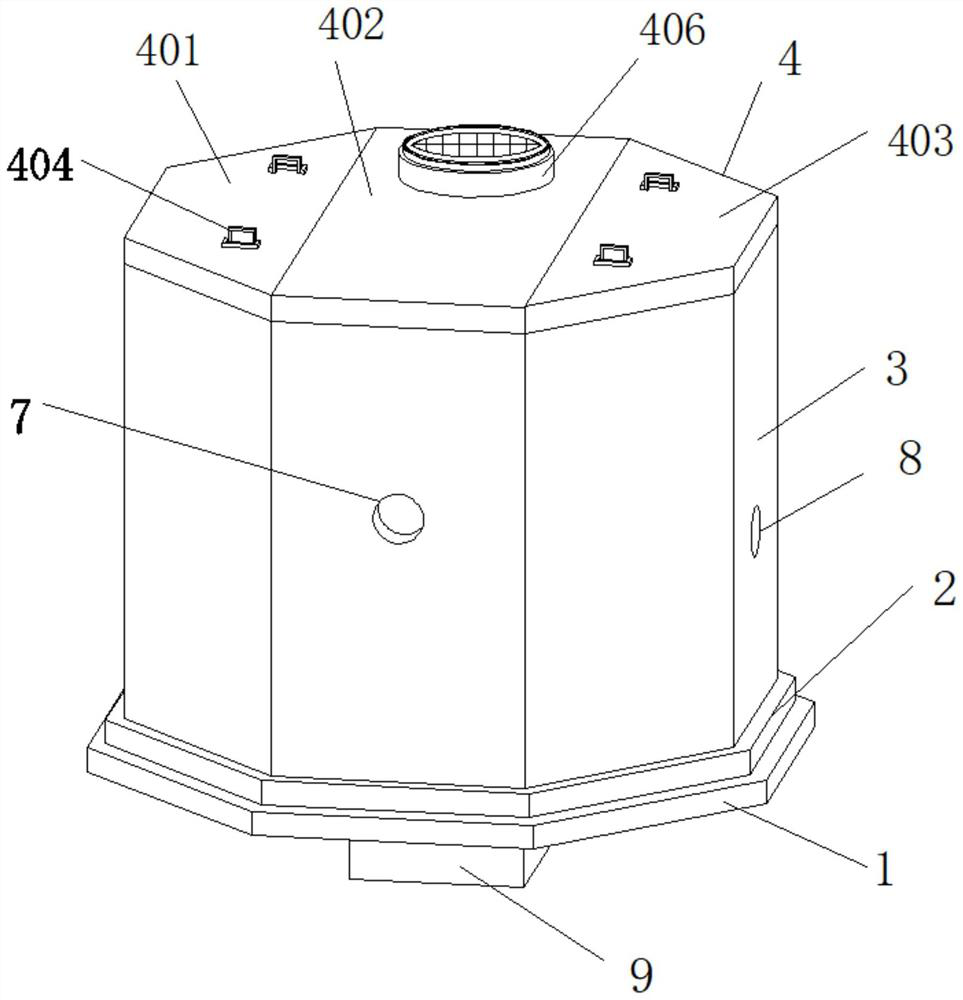

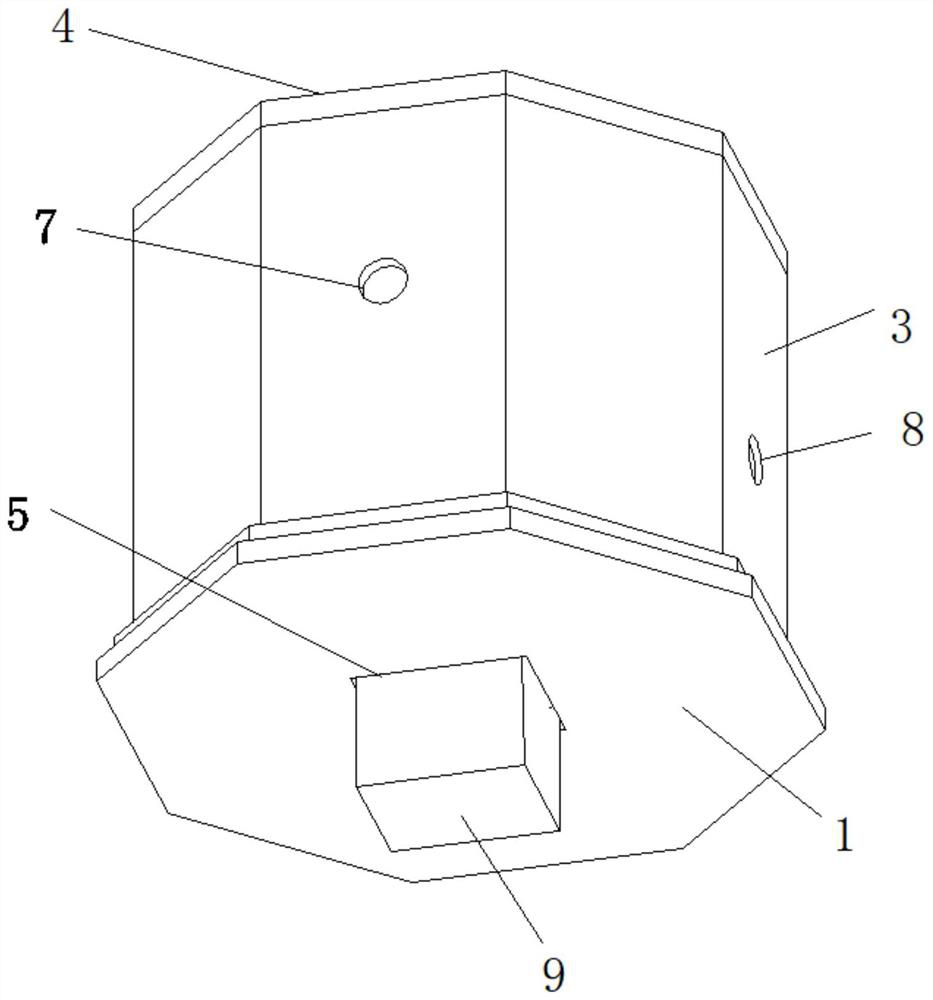

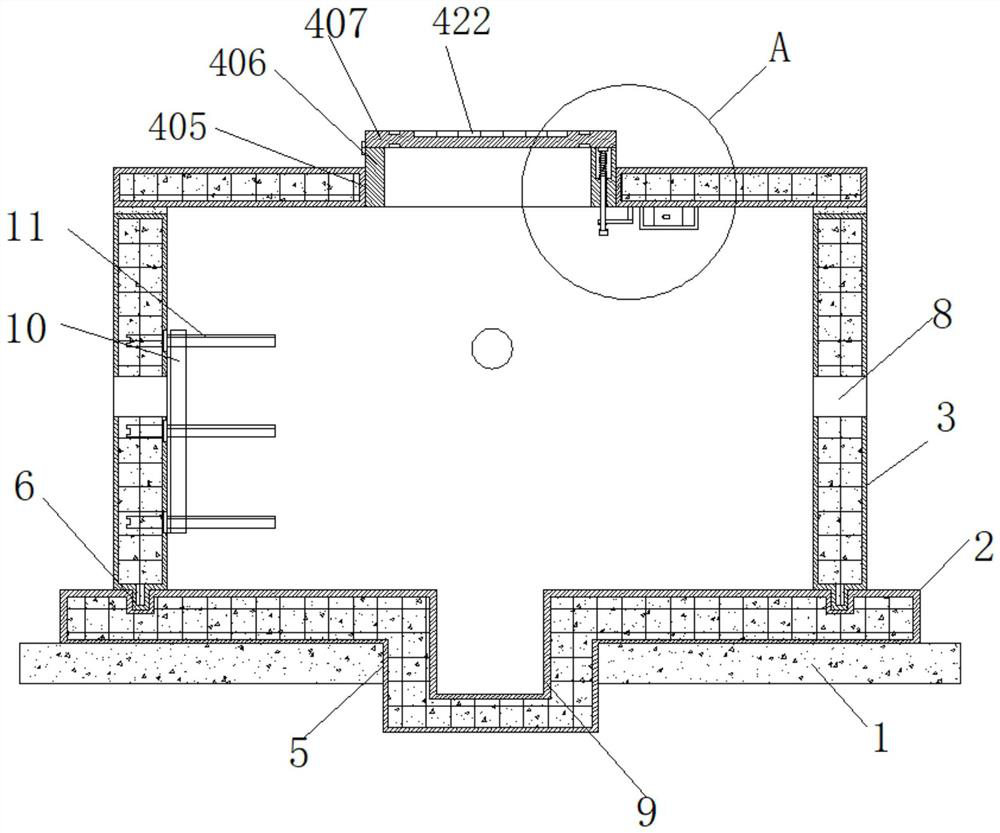

[0036] A prefabricated octagonal cable shaft, such as figure 1 and figure 2Shown, comprise base plate 1, base plate 2, side plate 3 and top cover 4, the upper surface center of base plate 1 is provided with square hole 5, and the upper end of base plate 1 is equipped with base plate 2; The center of base plate 2 is provided with Square water-collecting well 9, square water-collecting well 9 is set in square hole 5 inside, and water all can flow to square water-collecting well 9 inside, thereby can prevent octagonal cable well internal water accumulation, and ponding can produce potential safety hazard to the use of electric cable; Base plate The upper end surface of 2 is provided with eight installation grooves 6, and the eight installation grooves 6 are arranged according to the octagon, and a side plate 3 is installed between two adjacent installation grooves 6 by bolts, and the upper end of the upper end surface of the bottom plate 2 A total of eight side panels 3 are ins...

Embodiment 2

[0049] Embodiment two is on the basis of embodiment one, such as figure 1 As shown, the upper surface of the cast iron cover plate 407 is fixed with a solar panel 422, the solar panel 422 is electrically connected to the battery 421, the solar panel 422 can convert sunlight into electric energy and store it inside the battery 421, and the electric energy of the battery 421 can be used for the warning light belt 408 usage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com