Prefabricated building prefabricated wallboard convenient to connect and fix and mounting method thereof

An architectural and prefabricated technology, applied in the direction of protective buildings/shelters, buildings, building components, etc., can solve the problems of poor vertical and horizontal seismic performance of joints, mold growth, and easy damage to card slots, etc., to achieve Effect of Improving Vertical and Lateral Seismic Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

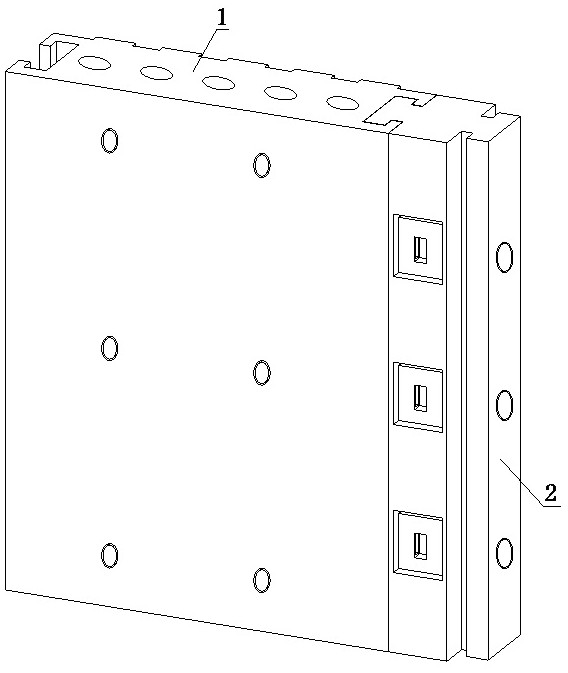

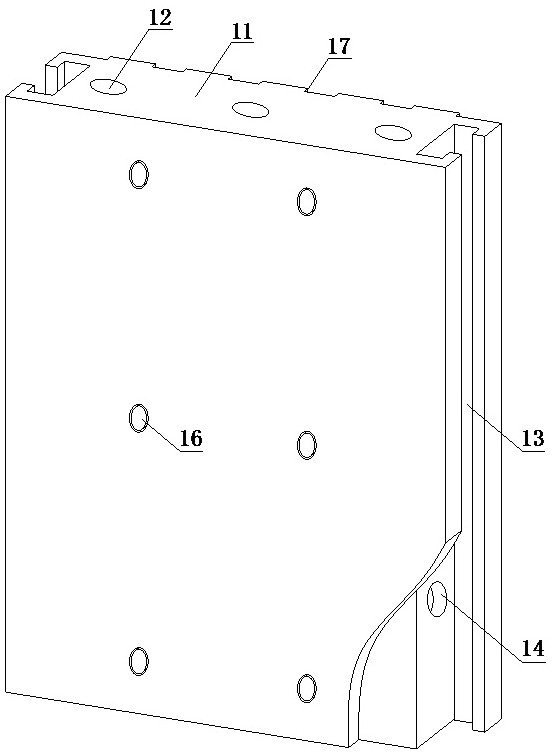

[0037] see Figure 1-3, an assembled wall panel for a prefabricated building that is easy to connect and fix, including a wall panel structure 1 and a connector 2, the connectors 2 are respectively arranged on the outer walls of both sides of the wall panel structure 1, and the wall panel structure 1 includes a wall panel body 11 , a through hole 12, a connecting slot 13, a limit hole 14, a mounting hole 15 and a connecting bolt 16, and the upper end of the wall panel body 11 is uniformly provided with a through hole 12, and the through holes 12 all penetrate from the top of the wall panel body 11 to the The bottom end of the wall panel body 11 is provided with a through hole 12 which helps to reduce the weight of the wall panel body 11 and facilitates its hoisting and transportation. The two side outer walls of the wall panel body 11 are respectively provided with a connecting slot 13, and the connection A number of limit holes 14 are evenly opened on the inner wall of the si...

Embodiment 2

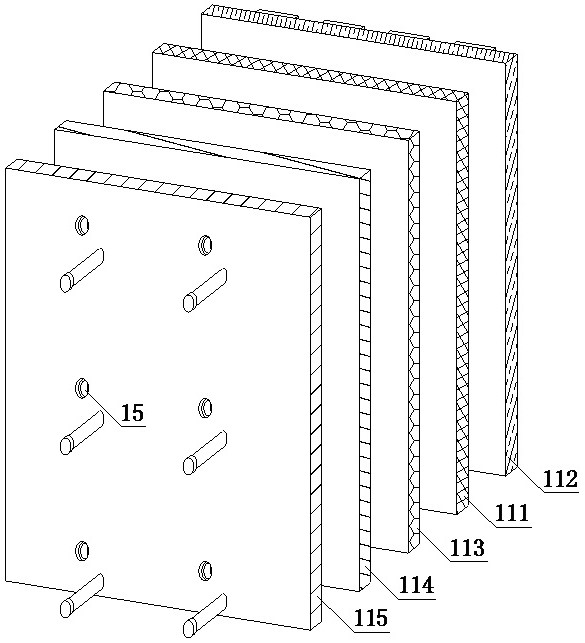

[0039] see image 3 , a prefabricated building is easy to connect and fix the assembled wall panel, the wall panel body 11 includes the main wall panel 111, the outer panel 112, the sound insulation panel 113, the thermal insulation panel 114 and the inner panel 115, one side of the main wall panel 111 The outer wall 112 is provided on the outer wall, and the outer wall of the main wall 111 away from the outer page 112 is provided with a sound insulation board 113, and the outer wall of the sound insulation board 113 away from the main wall 111 is respectively provided with a thermal insulation board 114 in turn. and the inner panel 115, the main wall panel 111, the outer panel 112, the sound insulation panel 113, the thermal insulation panel 114 and the inner panel 115 are fixedly connected by adhesive bonding and pressing, and are connected to each other through the mounting holes 15 on the side wall. The inner connecting bolts 16 run through the fixed connection, and the en...

Embodiment 3

[0041] see image 3 and Figure 4 , a prefabricated building with an assembled wall panel that is easy to connect and fix. The main wall panel 111 includes a steel mesh 1111 and a concrete piece 1112. A component made after the external pouring concrete has solidified and formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com