Novel compressor buffer tank

A technology of compressor and buffer tank, applied in the field of compressor buffer, can solve the problems of poor economic effect, occupying large space, reliability of compressor cylinder, and economical decline, so as to suppress gas pulsation, realize throttling effect, The effect of reducing overall length and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

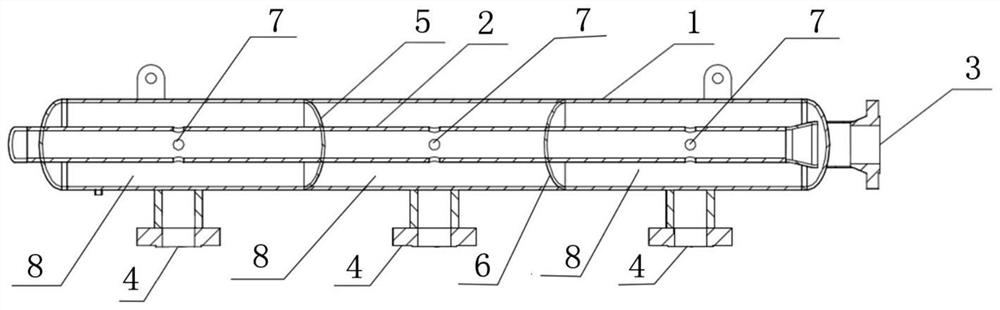

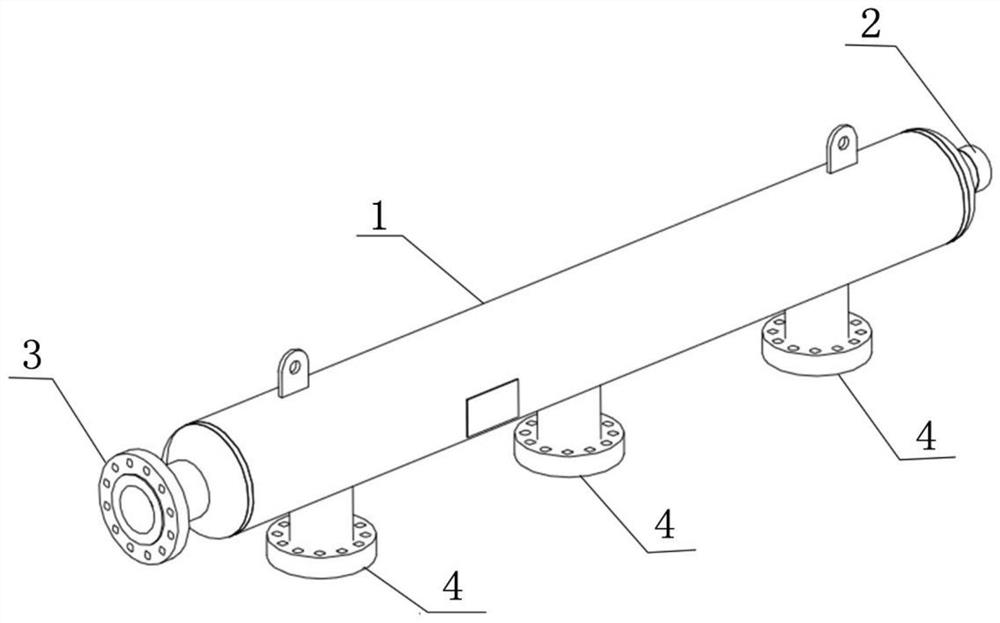

[0018] Such as Figure 1 to 2 As shown, a new type of compressor buffer tank includes a tank body 1, an internal pipe 2, an air inlet 3, an air outlet 4, a first inner head 5, a second inner head 6 and a vent 7, the first inner The head 5 and the second inner head 6 are respectively arranged inside the tank body 1. The first inner head 5 and the second inner head 6 separate the inside of the tank body 1 into three independent chambers 8. The internal pipe 2 is arranged in the tank body 1 and penetrates three chambers 8. The internal pipe 2 of each chamber 8 is provided with a vent 7 and an air inlet 3 is provided at one end of the tank body 1. The port 3 is connected with the internal pipeline 2, and an air outlet 4 is provided on the side wall of the tank 1, and the air outlet 4 is used for discharging the gas in the tank 1. In the buffer tank body 1, an inner head, a gas inner pipe 2 and a vent 7 are opened on the pipe to make the gas form an air inlet 3---internal pipe 2---...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com