Scale calibration device for self-inspection of mixing plant and scale calibration method thereof

A technology for mixing plant and calibrating scale, which is applied in the field of calibrating device for self-checking of mixing plant, can solve the problems of inability to perform calibrating in a timely and rapid manner, labor-intensive work, and long calibrating time, etc., so as to facilitate inquiry and reduce labor. Strength, easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

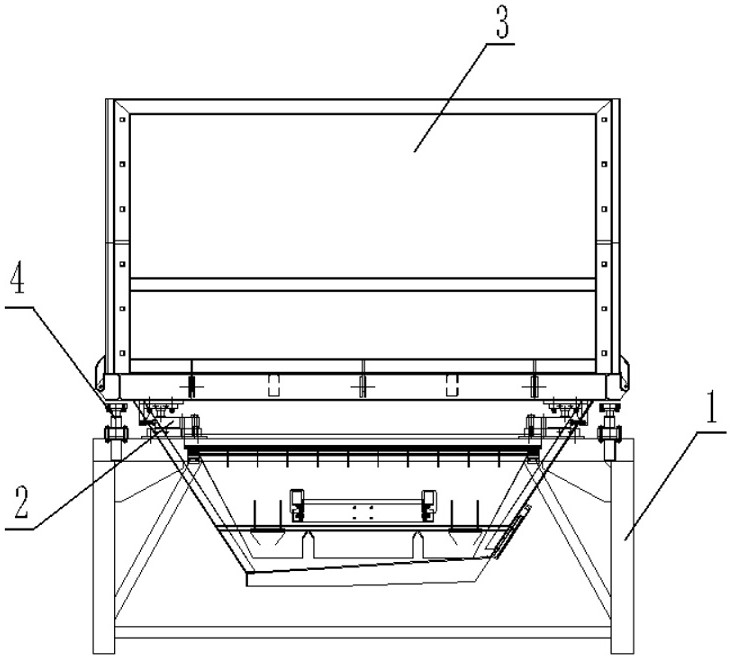

[0033] Such as figure 1 As shown, a self-checking scale calibration device for a mixing station includes a frame 1, a load cell 2, a weighing bucket 3, a jacking device 4, and a weighing system, and the load cell 2 is fixedly connected to the machine. On the frame 1 and between the weighing bucket 3 and the frame 1, the weighing bucket 3 is detachably connected to the load cell 2, and the jacking device 4 is used to drive the weighing bucket 3 to rise and falling, through the up and down movement of the jacking device 4, the weighing bucket 3 is driven to move up and down to realize the separation and contact between the weighing bucket 3 and the load cell 2; when the weighing bucket 3 contacts the load cell 2, the lifting device 4 is separated from the weighing bucket 3, and the weighing bucket 3 is supported by the weighing sensor 2; the weighing sensor 3 adopts a pressure-type weighing sensor; the jacking device 4 is fixedly connected to the frame 1, and the weighing The h...

Embodiment 2

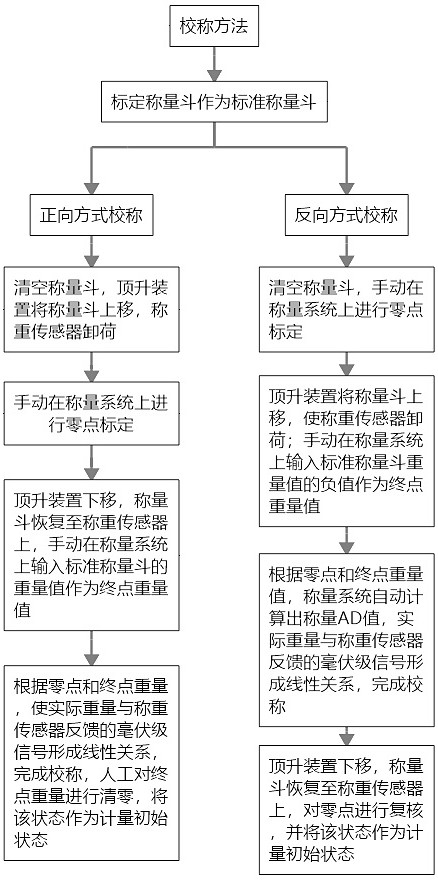

[0043] Such as figure 2 , Figure 4 As shown, when the reverse method is selected to calibrate the scale, the calibration method includes the following steps:

[0044] 1. Use weighing bucket 3 as a standard weighing bucket;

[0045] 2. Empty the weighing bucket 3, and manually calibrate the value of the load cell 2 on the weighing system;

[0046] 3. The lifting device 4 moves the weighing bucket 3 up, so that the weighing bucket 3 is separated from the load cell 2, and the load cell 2 is unloaded; manually input the negative value of the standard weighing bucket weight value on the weighing system as the end point weight value;

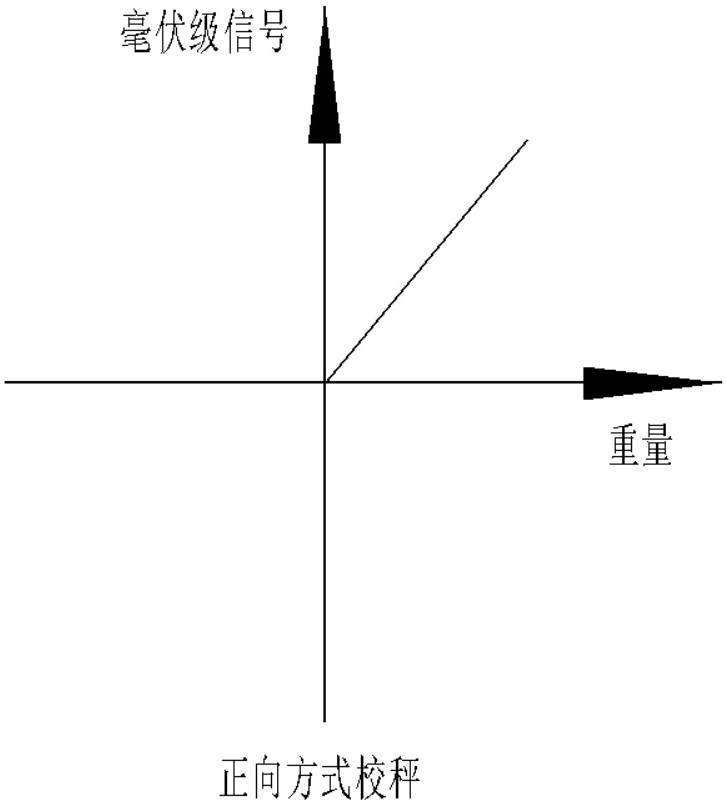

[0047] 4. According to the zero point and end point weight value, the weighing system automatically calculates the weighing AD value, so that the actual weight and the millivolt level signal fed back by the load cell 2 form a linear relationship, and the calibration is completed;

[0048] 5. Move the jacking device 4 down, restore the weighing b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com