Metal shell button type lithium ion battery

A technology of lithium-ion batteries and metal shells, which is applied in the direction of batteries, cylindrical shell batteries/batteries, secondary batteries, etc., can solve the problem that the good sealing of the inner shell and the outer shell cannot be fully guaranteed, and the battery product cannot make full use of the diameter direction space, battery products can not make full use of the axial space and other issues, to achieve the effect of simple structure, improved energy density, and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

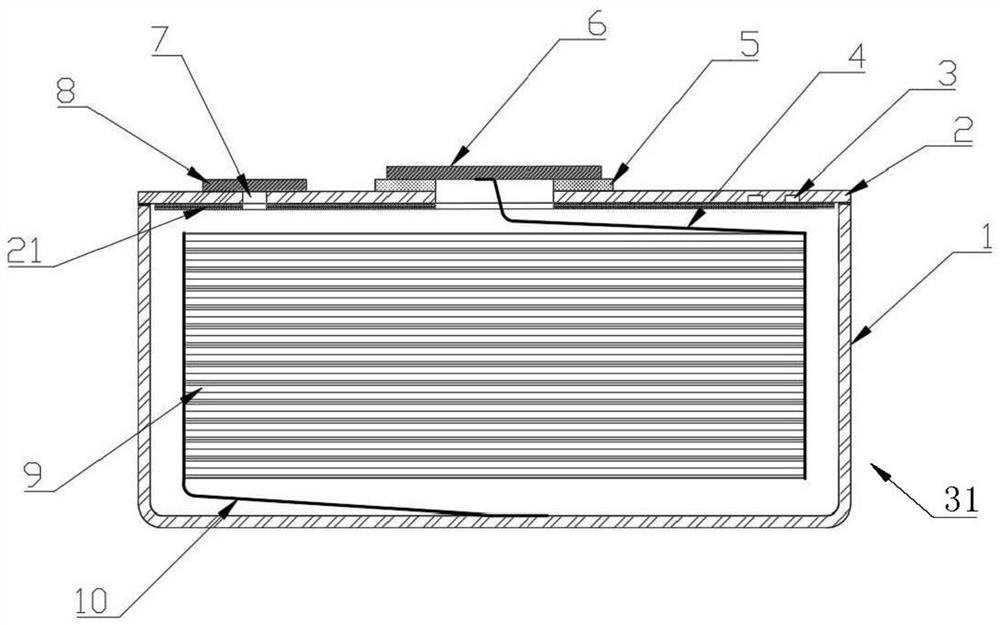

[0025] The invention provides a metal shell button lithium ion battery, such as figure 2 Shown is a schematic cross-sectional view of the battery, which includes a metal case 31, a battery cell 9 installed inside the metal case 31, a terminal 6 installed outside the metal case 31, and a terminal 6 installed between the metal case 31 and the terminal. The insulator 5 between the 6 and the metal shell 31 and the terminal 6 are insulated and sealed respectively, and the electric core 9 is provided with at least one first pole ear that is electrically connected to the metal shell 31 and has positive or negative polarity 10. The electric core 9 is also provided with at least one second tab 4 electrically connected to the terminal 6 and having negative or positive polarity, and the polarity of the metal shell 31 is opposite to that of the terminal 6, The metal shell 31 and the terminal 6 are hermetically connected to the insulator 5 by heat sealing or adhesive respectively, wherein...

Embodiment 2

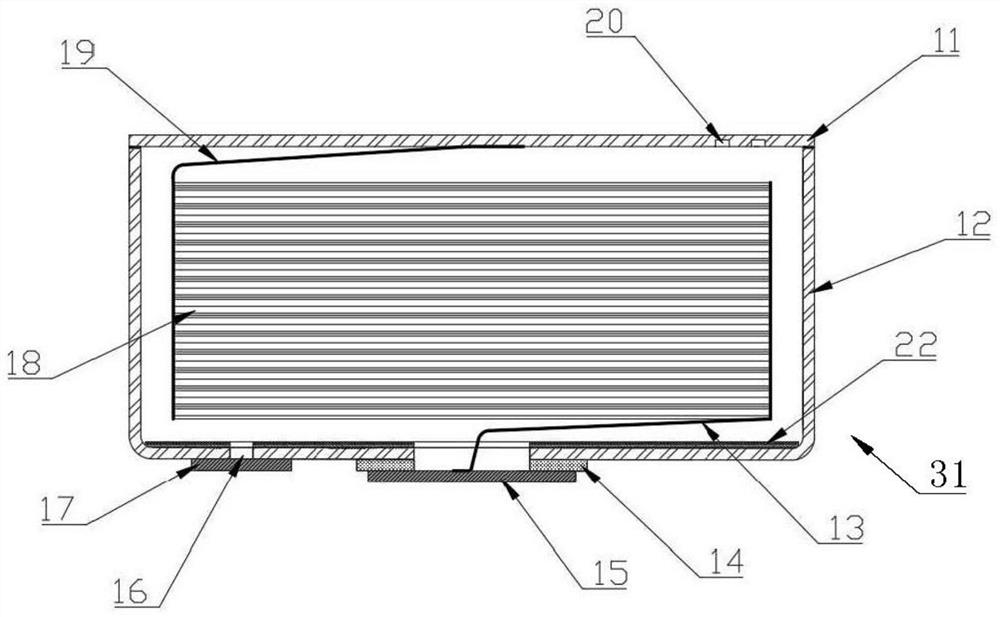

[0034] The present invention provides another metal shell button lithium ion battery, which includes a metal shell 31, such as image 3 Shown is a schematic cross-sectional view of the battery, the cell 18 installed inside the metal case 31, the terminal 15 installed outside the metal case 31, installed between the metal case 31 and the terminal 15 and respectively connected to the metal case 31. The shell 31 and the terminal 15 are insulated and sealed insulators 14. The electric core 18 is provided with at least one first tab 19 electrically connected to the metal shell 31 and having positive or negative polarity. The electric core 18 There is also provided at least one second tab 13 electrically connected to the terminal 15 and having negative or positive polarity. The polarity of the metal shell 31 is opposite to that of the terminal 15. The metal shell 31 and the The terminals 15 are hermetically connected to the insulator 14 by heat sealing or adhesive respectively, wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com