Inverted LED light source

A technology of LED light source and LED chip, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of increasing heat transportation distance, reducing device reliability, increasing thermal resistance, etc., to improve chip yield and reduce thermal stress , The effect of reducing thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

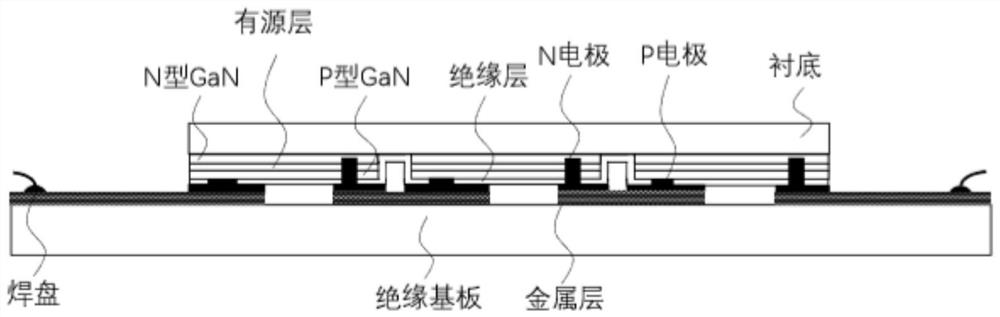

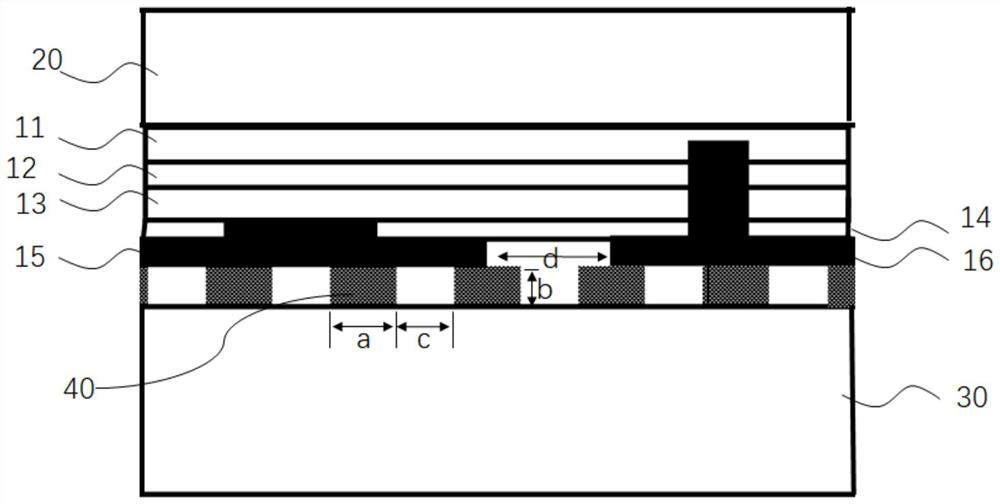

[0034] see image 3 and Figure 4 , a flip-chip LED light source, including a substrate 30 and at least one LED chip 10, the LED chip 10 is combined with the front surface of the substrate 30 with a first surface having electrodes, and the second surface of the LED chip 10 is a light-emitting surface and is opposite to the first surface. back to.

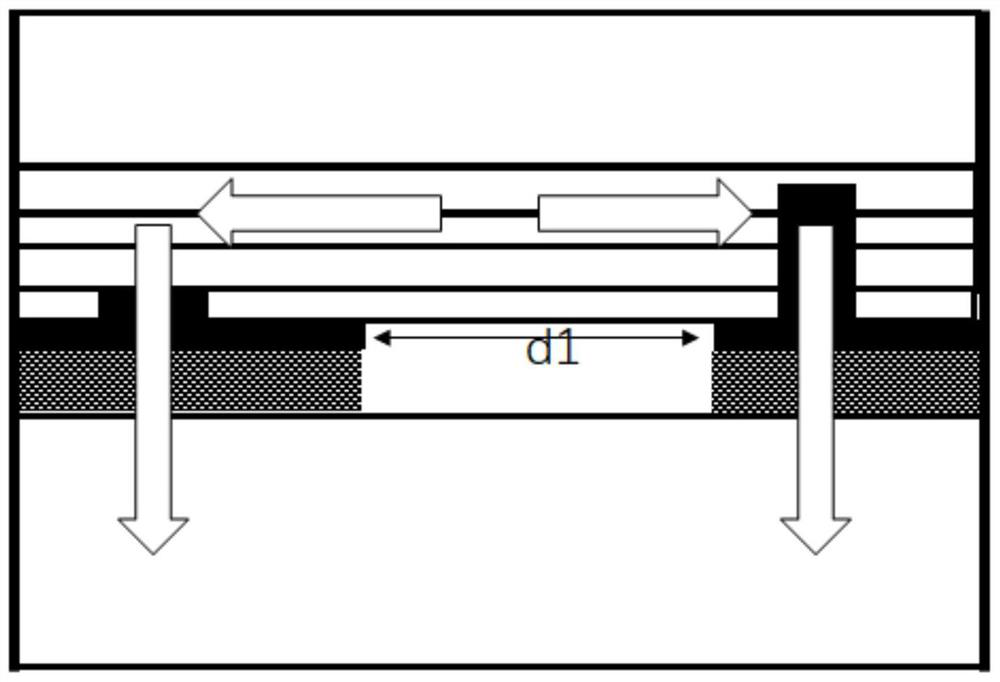

[0035] Wherein, the LED chip is a high-voltage and high-power integrated flip chip with good flatness, and the epitaxial layer of the LED chip 10 may include an N-type GaN layer 11, an active layer 12, and a P-type GaN layer formed on the substrate 20 in sequence. layer 13; further, an insulating layer 14 can also be provided on the epitaxial layer; the epitaxial layer is processed to form a plurality of unit cells arranged in an array, and the plurality of unit cells are connected in series and / or in parallel, each Each unit cell cooperates with a P electrode 15 and an N electrode 16, and the P electrode 15 and the N electrode 16...

Embodiment 2

[0044] see Figure 5 , the structure of a flip-chip LED light source in this embodiment is basically the same as that of the flip-chip LED light source in Embodiment 1, the difference is that no external leads are provided on the front side of the insulating substrate 30 in this embodiment 60, and the conductive layer 53 and the conductive layer 54 are arranged at intervals on the back side of the insulating substrate 30, and the pad 51 and the pad 52 respectively pass through the conductive channel 31 and the conductive channel 32 of the substrate 30 to connect with the conductive layer 53 arranged on the back side of the substrate respectively. 1. The conductive layer 54 is electrically connected, so that electrical leads can be drawn out from the back of the insulating substrate. Both the conductive channel and the conductive layer can be made of metal, which is more conducive to timely transfer of the heat generated by the LED chip.

[0045] In some more specific embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com