Full-automatic rice polisher

A polishing machine, fully automatic technology, applied in the direction of grain smoothing, solid separation, separation of solids from solids by air flow, etc., can solve the problems of easy to produce broken rice, difficult rice, uneven polishing, etc., and achieve good polishing effect. , The effect of reducing broken rice and increasing cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

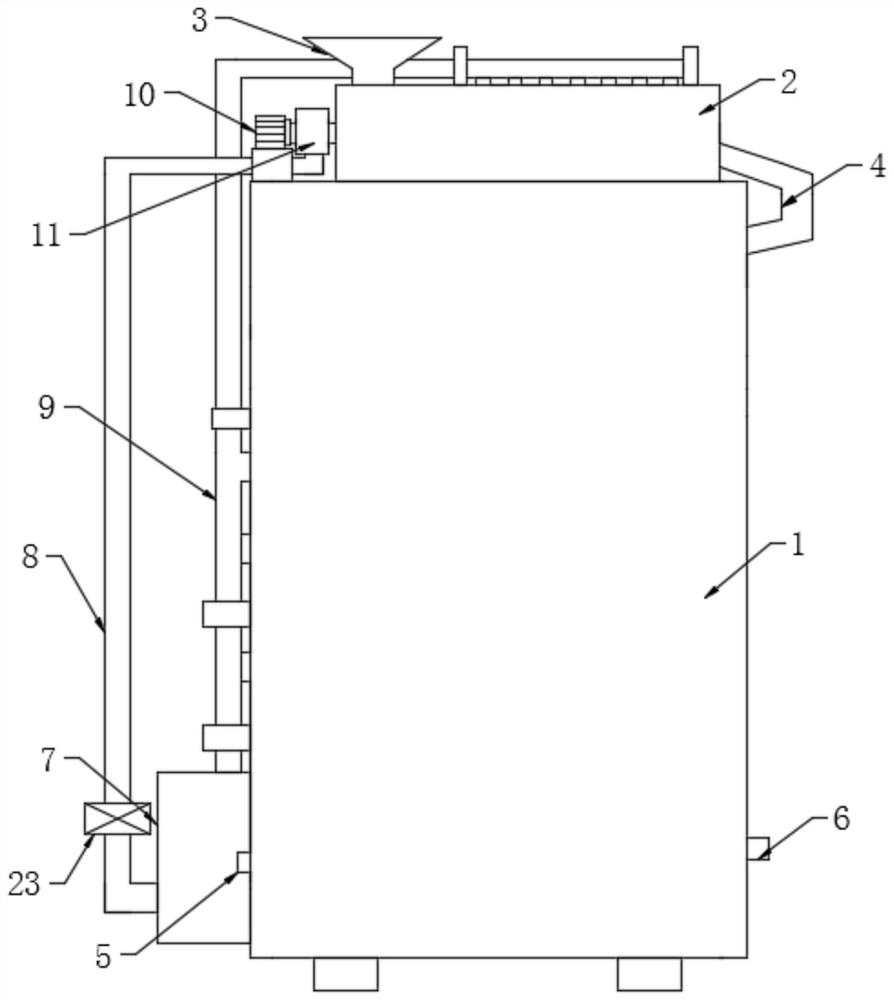

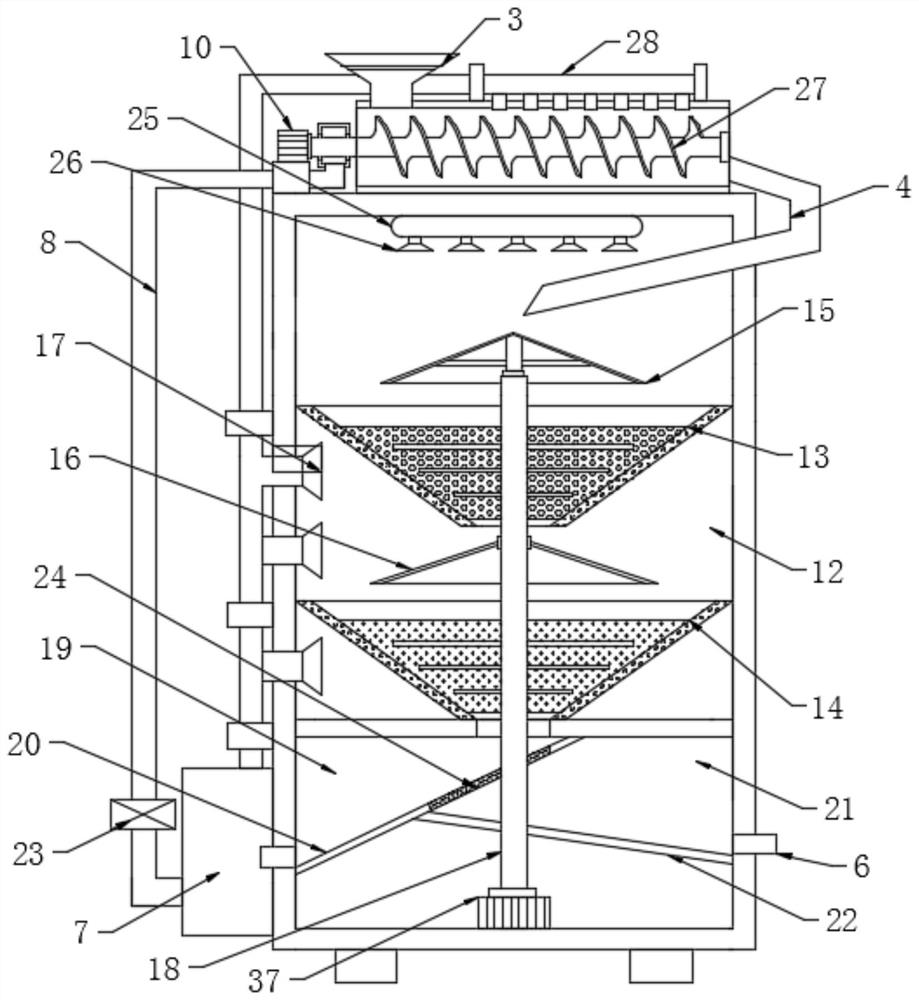

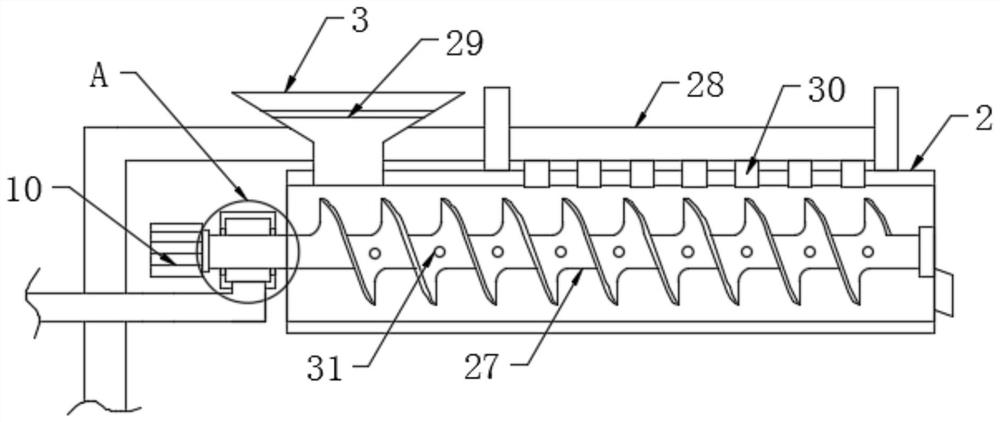

[0026] like Figure 1-4 As shown, the present invention provides a technical solution: a full-automatic rice polishing machine, comprising a casing 1, a screening mechanism, a polishing mechanism and a material distribution mechanism, the screening mechanism is located at the top of the casing 1, and the polishing mechanism And distributing mechanism are all positioned at casing 1 inside, and described polishing mechanism comprises polishing chamber 12, first polishing groove 13, second polishing groove 14 and rotating shaft 18, and described first polishing groove 13, second polishing groove 14 are all fixed Installed inside the polishing chamber 12, the inner bottom of the box body 1 is provided with a second motor 23, the output shaft of the second motor 23 is fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com