Colored steel plate on-line strip dividing device for PCM color coating wires

A technology of slitting device and color steel plate, which is applied in the direction of shearing device, accessory device of shearing machine, shearing machine equipment, etc., can solve the problem that color steel plate of different width cannot be cut, and achieve the effect of preventing deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

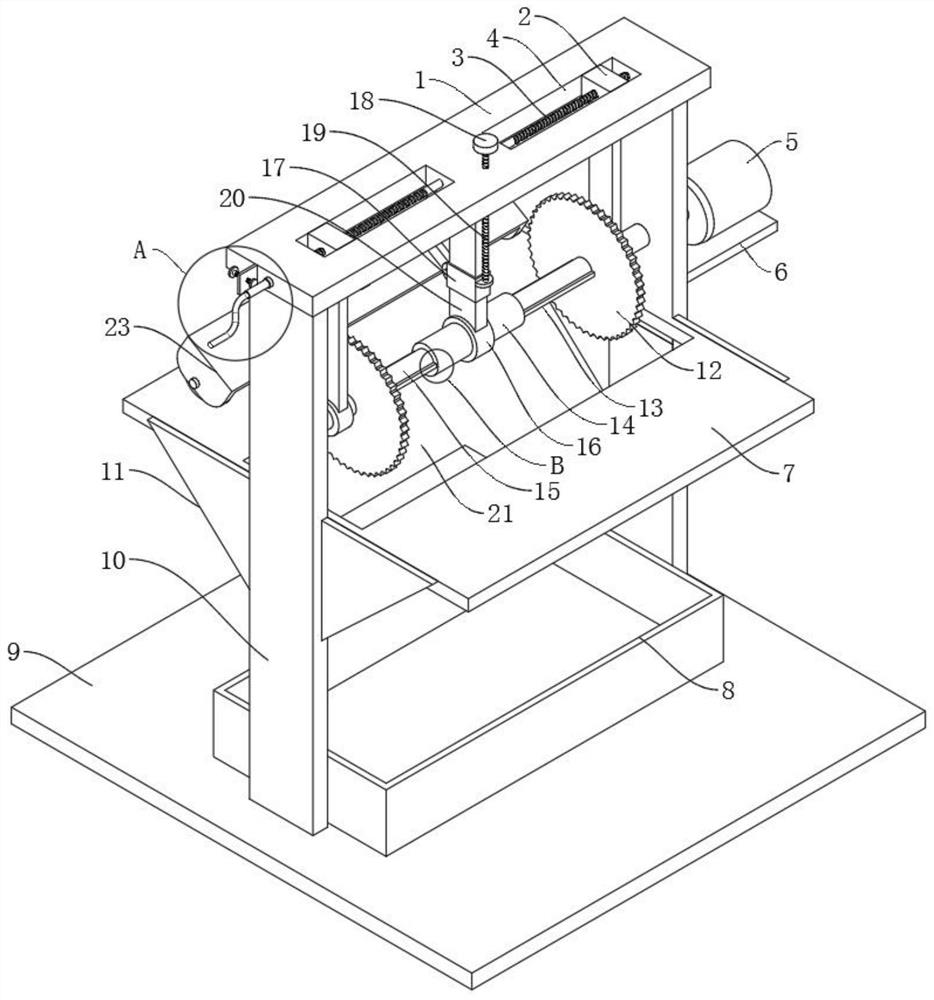

[0022] refer to Figure 1-5 , a color steel plate online slitting device for a PCM color coating line, comprising a base plate 9, both sides of the base plate 9 are fixedly connected with support legs 10, and the middle positions of the two support legs 10 are fixedly connected with a support plate 7, and the support legs 10 A reinforcing rib 11 is fixedly connected with the supporting plate 7, and the design of the reinforcing rib 11 facilitates the fixing effect between the supporting leg 10 and the supporting plate 7.

[0023] The support plate 7 is provided with a collection mechanism, the collection mechanism includes a through groove 21 provided in the middle of the support plate 7, a collection box 8 is placed on the bottom plate 9, the collection box 8 is located directly below the through groove 21, and the Designed to collect the debris falling from the through groove 21.

[0024] The upper end of the support leg 10 is fixedly connected with a top plate 1, one of th...

Embodiment 2

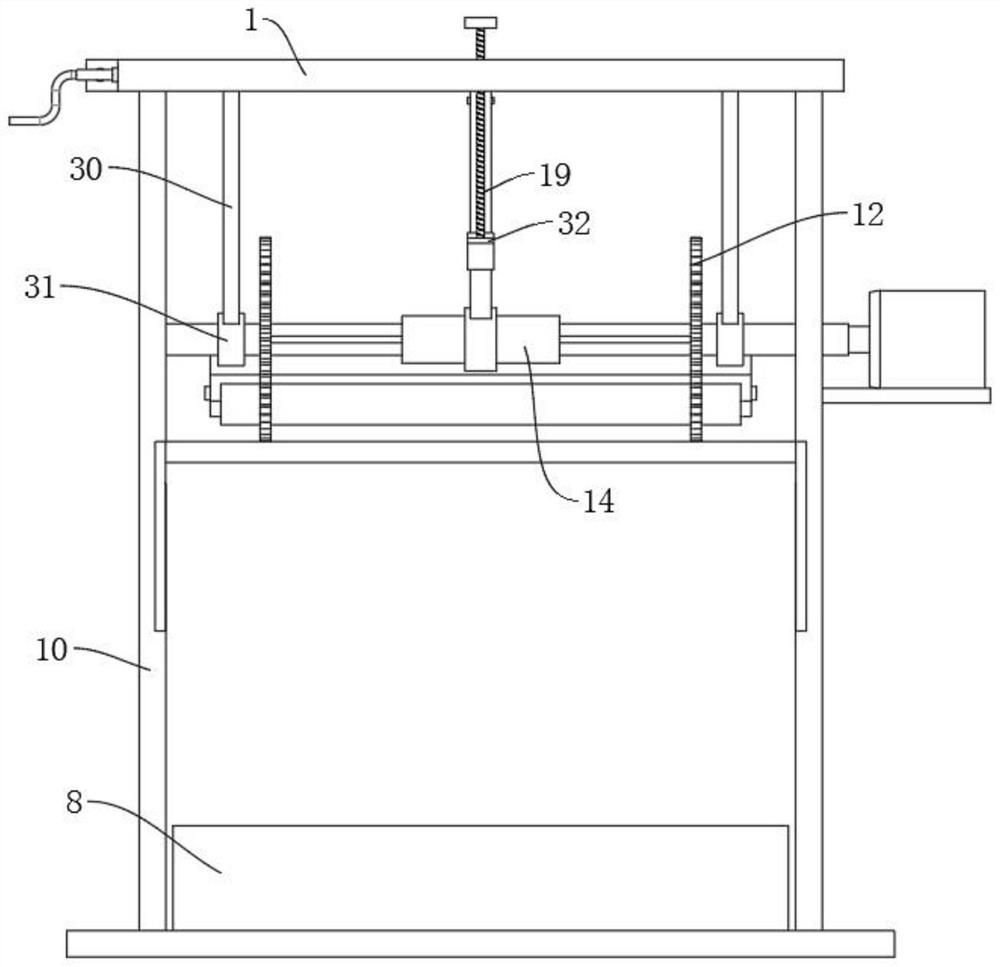

[0027] refer to figure 1 and Figure 6 , as another preferred embodiment of the present invention, on the basis of Embodiment 1, the abutment mechanism includes a fixed plate 27 fixedly connected with the top plate 1, and a fastening bolt 28 is threaded through the fixed plate 27, and one end of the fastening bolt 28 An abutting block 29 is fixedly connected, and the abutting block 29 is abutted against the connecting shaft 3 by turning the fastening bolt 28 , thereby preventing the connecting shaft 3 from rotating and enhancing the fixing effect on the connecting shaft 3 .

Embodiment 3

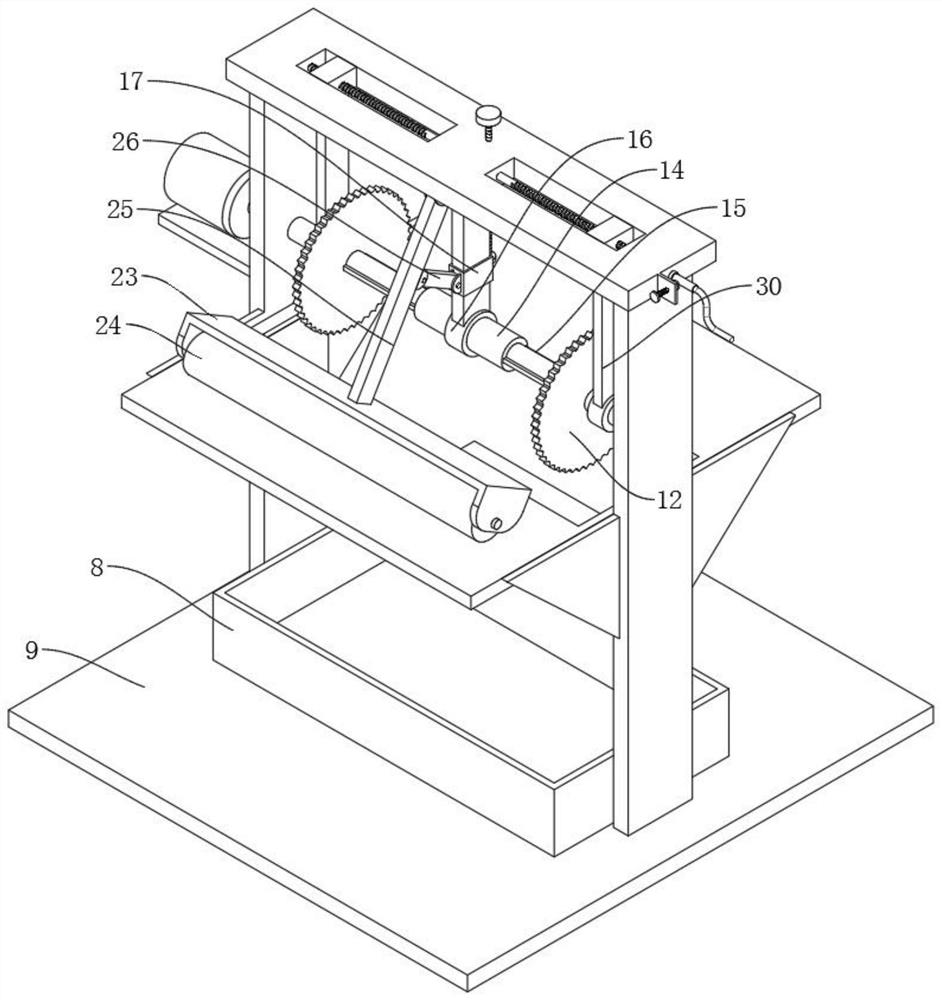

[0029] refer to Figure 1-4 , as another preferred embodiment of the present invention, on the basis of Embodiment 1, the adjustment mechanism includes a first hinged rod 25 hinged with the top plate 1, the first hinged rod 25 is fixedly connected with a connection shell 23, and the connection shell 23 It is connected with the pressing roller 24 through bearing rotation, the supporting rod 20 is covered with a moving sleeve 17, the second hinged rod 26 is hinged between the moving sleeve 17 and the first hinged rod 25, the moving sleeve 17 is fixedly connected with a moving seat 32, The moving seat 32 is connected with the threaded rod 19 through bearing rotation, the moving seat 32 and the threaded rod 19 adopt thrust ball bearings, the thrust ball bearings can bear the axial force, the threads of the threaded rod 19 run through the top plate 1, and the upper end of the threaded rod 19 is fixedly connected with a rotating The knob 18, by turning the threaded rod 19, will driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com