Treatment device for waste rubber tires

A processing device and waste rubber technology, applied in grain processing, presses, mechanical material recycling, etc., can solve the problems of no protective device, tire jumping, inconvenient waste tire progressive crushing operation, etc., to achieve convenient and quick removal, simple and convenient crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

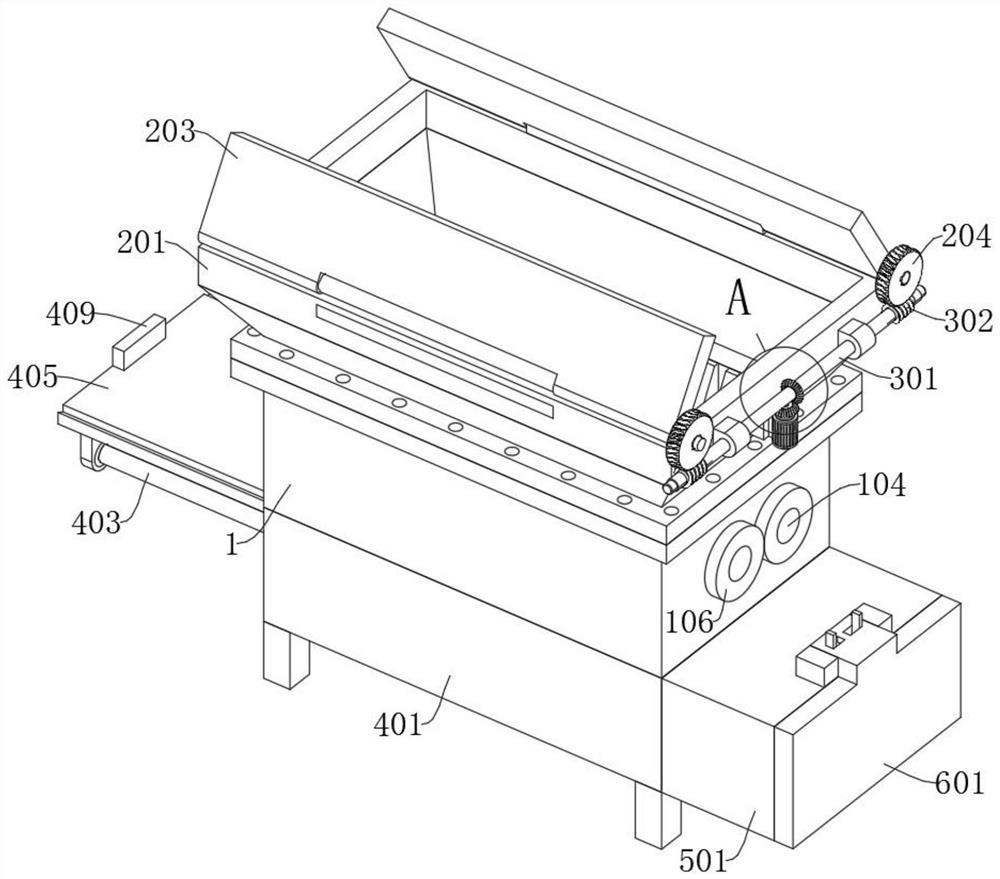

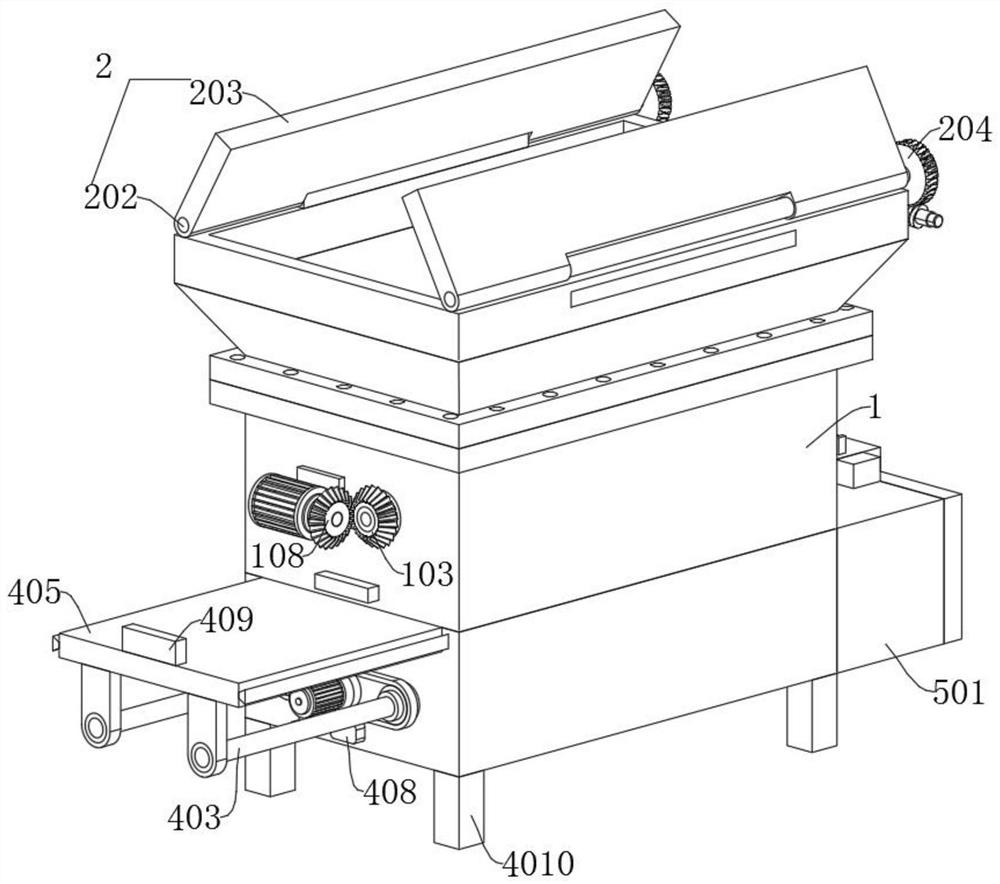

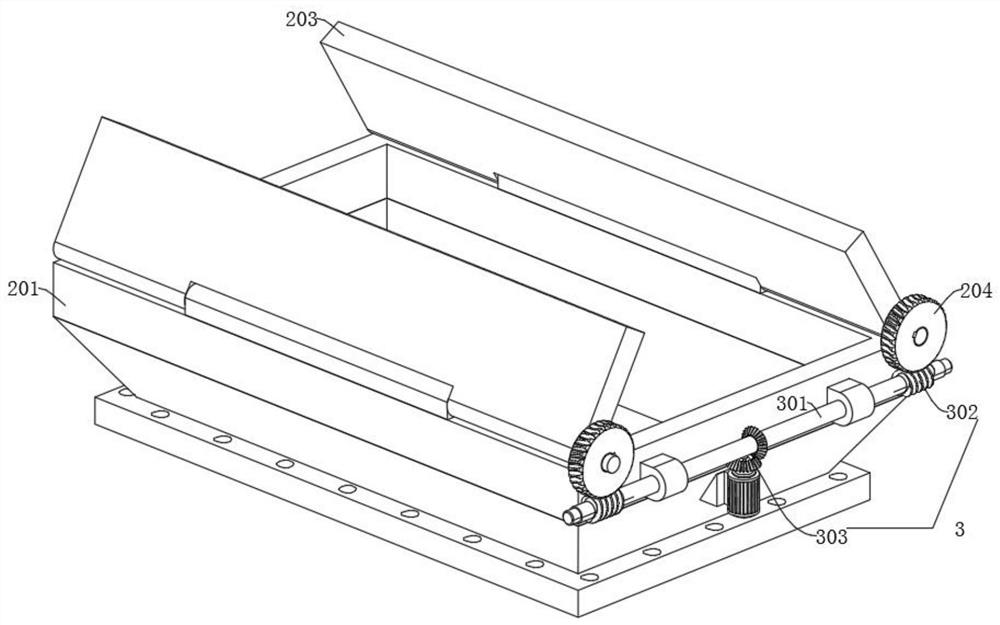

[0070] as attached figure 1 to the attached Figure 10 shown:

[0071] The present invention provides a processing device for waste rubber tires, which includes a device main body 1; the device main body 1 includes: a first rotating shaft 101, a first crushing tooth 102, a bevel gear A103, a second rotating shaft 104, and a second crushing tooth 105 , connecting the gear 106, the crushing plate 107 and the bevel gear B108, the outer side of the first rotating shaft 101 is fitted with a bearing, and the outer side of the bearing is fitted inside the device main body 1; the first crushing tooth 102 is fixedly arranged on the outer side of the first rotating shaft 101 , and the first crushing teeth 102 are fixed in a path array; the bevel gear A103 is fixedly arranged on the top of the first rotating shaft 101; the outer side of the second rotating shaft 104 is fitted with a bearing, and the outer side of the bearing is fitted inside the device main body 1; the second The crush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com