Raw material cutting equipment for shoe processing

A technology of raw materials and equipment, applied in the field of raw material cutting equipment for shoe processing, can solve the problems of increased production cost, waste of raw materials, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

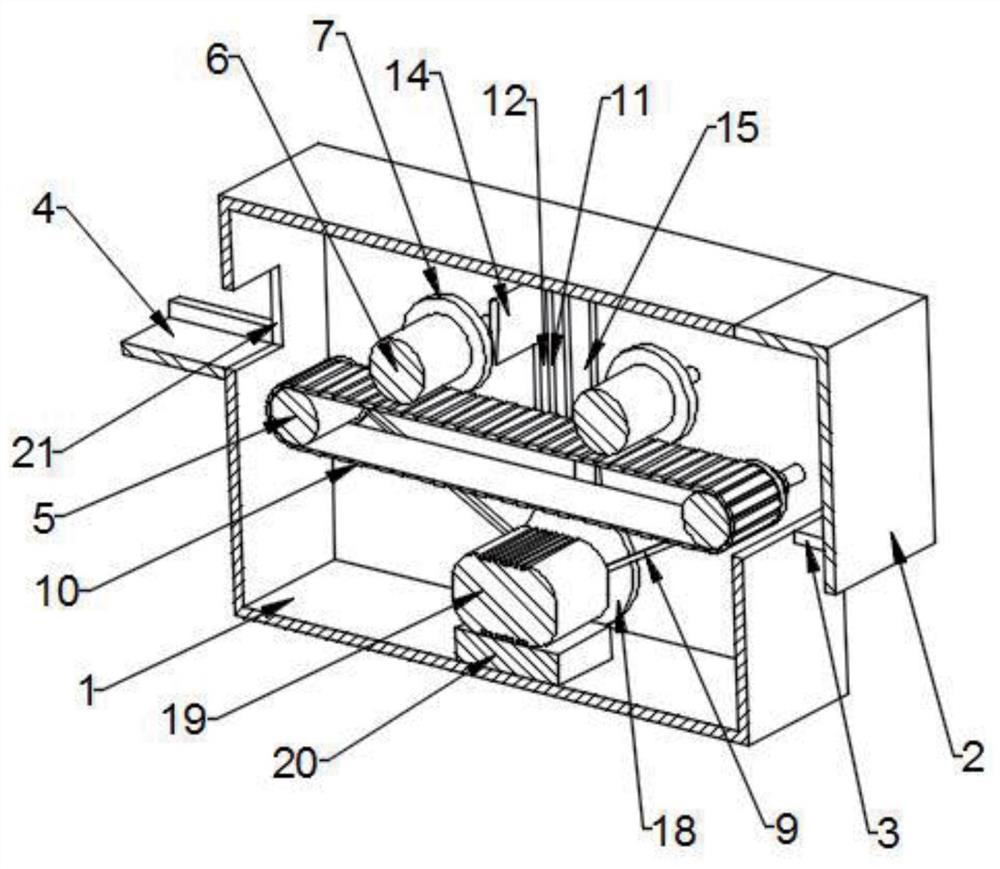

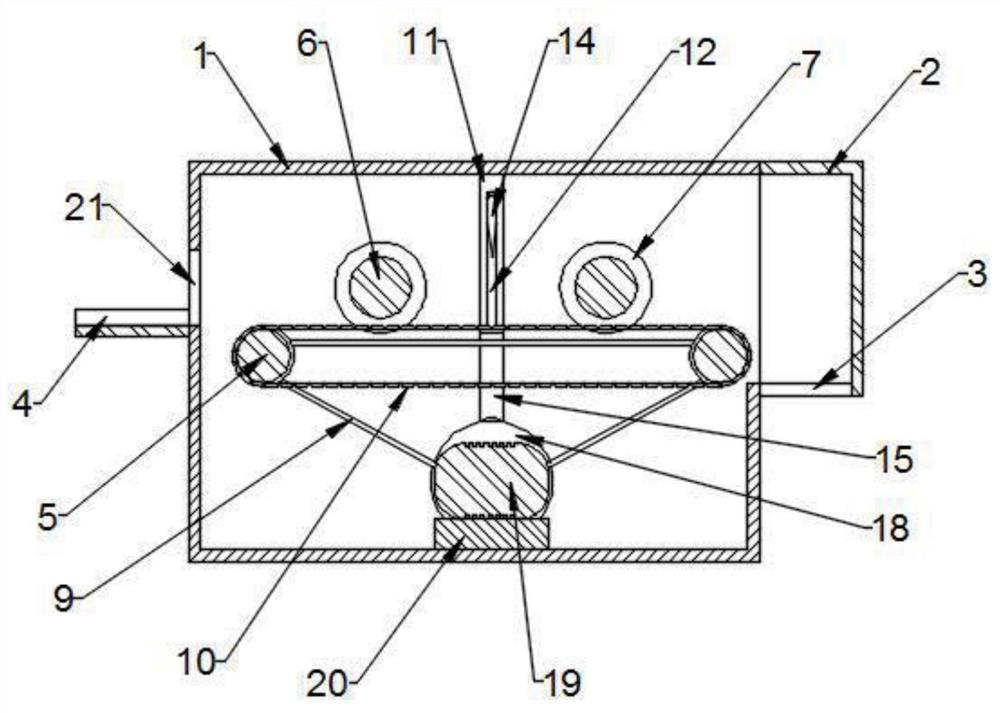

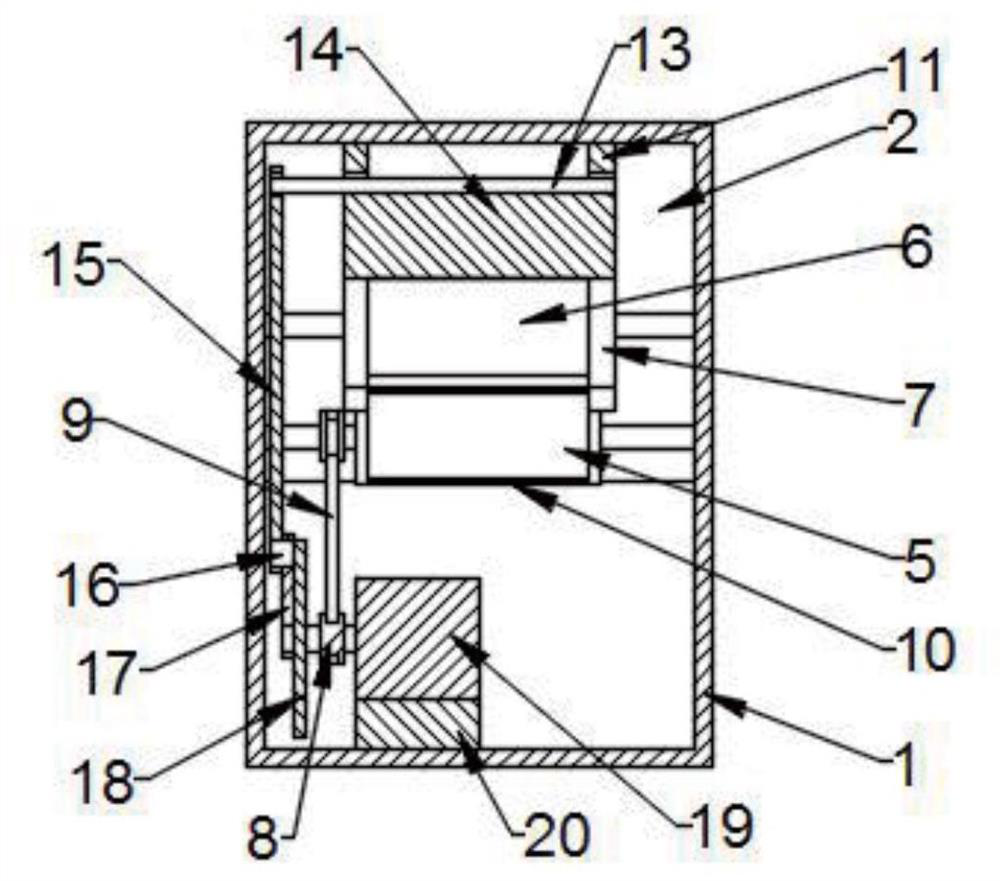

[0021] see Figures 1 to 5 , a raw material cutting equipment for shoe processing, comprising a box body 1, a limit block 11 in a vertical state is fixedly installed on both sides of the middle part of the inner surface of the upper end of the box body 1, and the middle part of the two sides of the limit block 11 is fixed. A limit slot 12 in a vertical state is spaced apart, a sliding rod 13 is inserted between the upper ends of the limit slot 12, a blade 14 is fixedly installed on the outer ring surface of the lower side of the sliding rod 13, and both ends of the blade 14 extend into In the limiting groove 12, both ends of the inner middle of the box body 1 are provided with rotating wheels 5 in a horizontal state, and the crawler belts 10 are jointly installed between the outer surfaces of the wheels of the rotating wheels 5. The movable shaft and the bearing are connected with the inner surface of the box body 1. The middle part of the inner and lower ends of the box body ...

Embodiment 2

[0023] see Figures 1 to 5 , in the case where other parts are the same as in Embodiment 1, the difference between this embodiment and Embodiment 1 is that the upper side of the middle part of the outer surface of the front end of the box body 1 is fixedly installed with a horizontal discharge plate 4, which is located in the discharge plate. The surface of the box body 1 on the upper side of the plate 4 is provided with a feeding port 21, and the upper side of the outer surface of the rear end of the box body 1 is fixedly installed with a mask box 2. The middle part of the lower surface of the cover box 2 is provided with a discharge opening 3, and both sides of the upper middle part of the crawler belt 10 are provided with horizontal rollers 6. The middle part of the side of the disc 7 away from the roller 6 is connected with the inner surface of the box body 1 through the movable shaft and the bearing. 4. It is pushed to the top of the crawler belt 10 through the feeding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com