Plastic particle mixing device for electronic product plastic shell production

A plastic shell and plastic granule technology, which is applied in the field of plastic granule mixing devices for the production of plastic shells of electronic products, can solve the problems of affecting the quality of mixing, poor mixing effect, and sticking together of plastic granules, so as to improve the mixing effect , It is convenient for the timing of the discharge, and the effect of improving the effect of the air intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

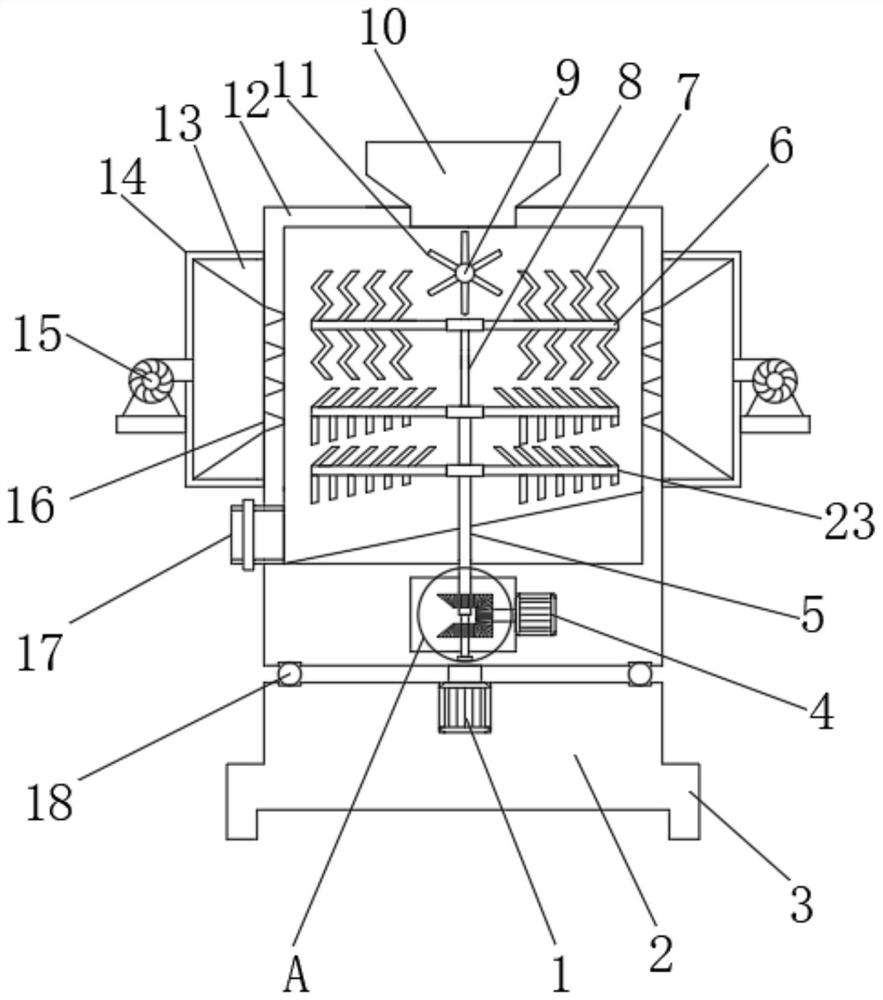

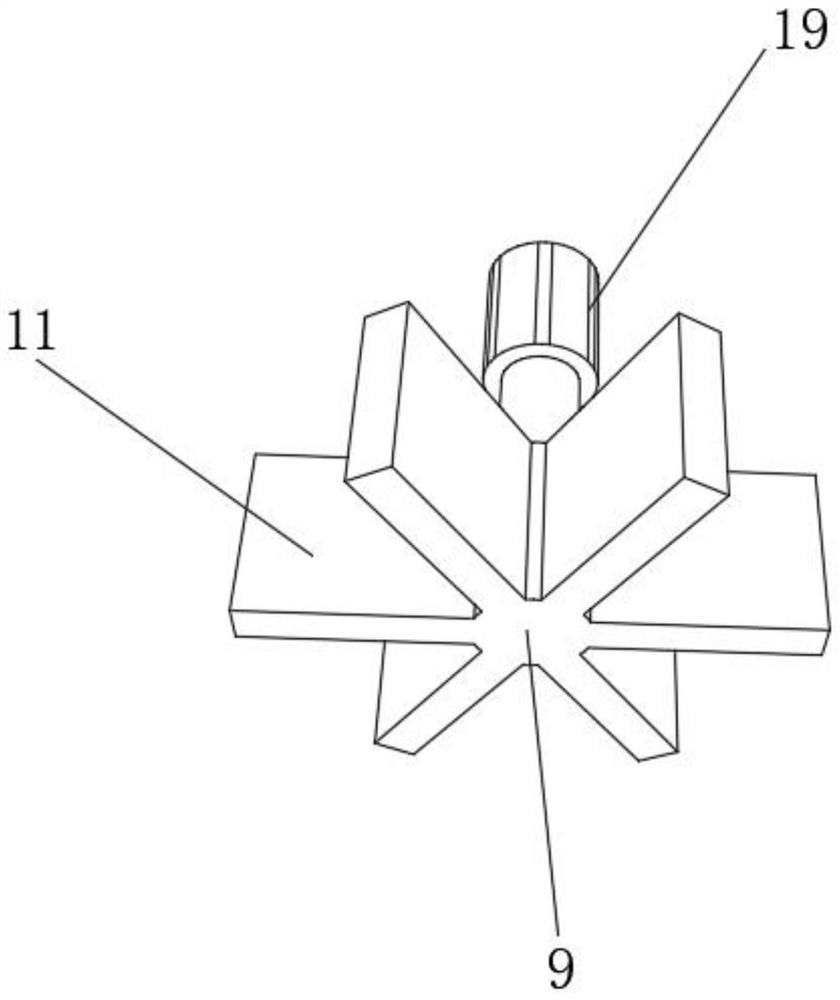

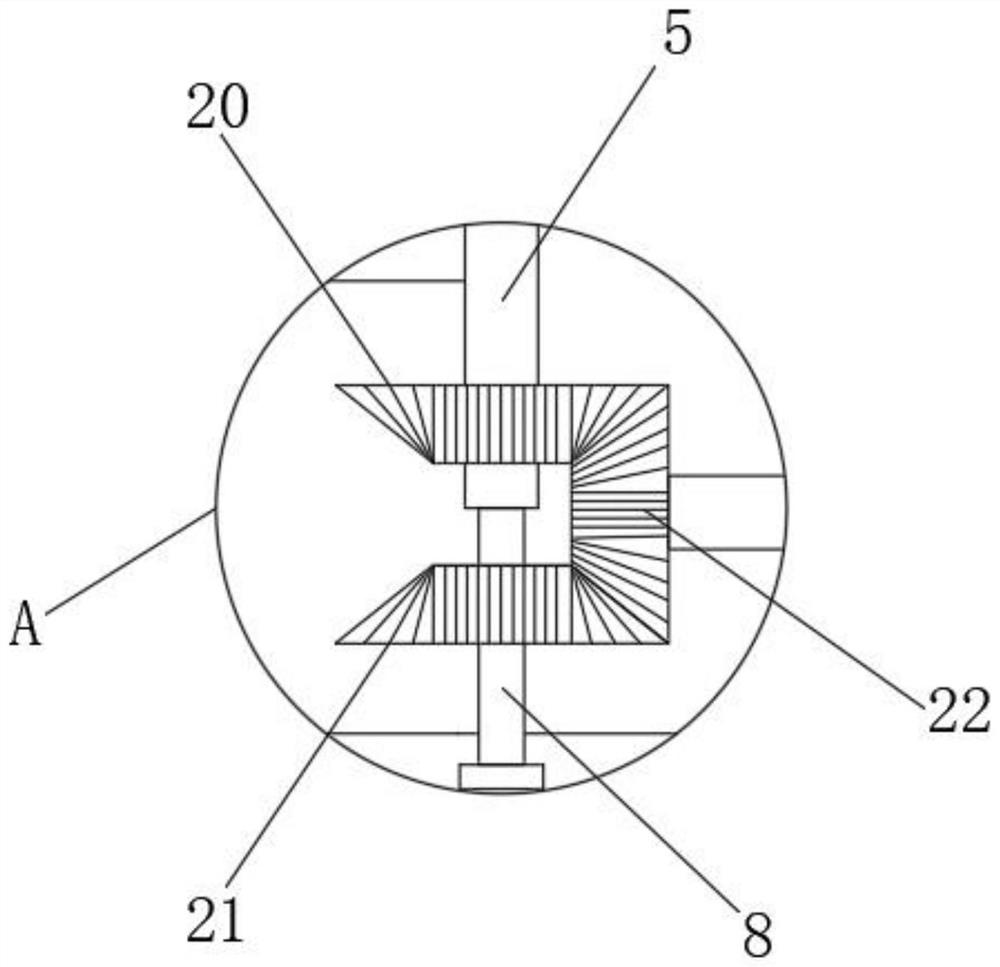

[0029] refer to Figure 1-4 , a plastic particle mixing device for the production of plastic shells of electronic products, including a base 2, a fixing groove is opened on the top outer wall of the base 2, and a driving motor 1 is arranged on the inner wall of the fixing groove, and the output shaft of the driving motor 1 passes through a shaft coupling The mixer is connected with a stirring box 12, and the interior of the stirring box 12 is provided with a cavity, the bottom inner wall of the cavity is connected with an inner rotating rod 8 through a bearing, and the outer wall of the inner rotating rod 8 is sleeved with a second bevel gear 21, the inner rotating The outer wall of the rod 8 located above the second bevel gear 21 is sleeved with the outer rotating tube 5, and the outer wall of the outer rotating tube 5 is sleeved with the first bevel gear 20, and the outer wall of the outer rotating tube 5 located above the first bevel gear 20 is sleeved There are fixed rings...

Embodiment 2

[0039] refer to Figure 5 , a plastic particle mixing device for the production of plastic shells of electronic products. Compared with Embodiment 1, this embodiment also includes an observation port on one side of the outer wall of the stirring box 12, and a transparent glass plate 27 is provided on the inner wall of the observation port.

[0040] Through the transparent glass plate 27, it is convenient to observe the progress of mixing the plastic particles, and it is convenient for workers to judge the timing of discharging after mixing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com