Thermal transfer printing method for non-woven fabrics

A printing method and technology of non-woven fabrics, applied in printing, printing process, printing of special varieties of printed matter, etc., can solve the problems of low printing quality, poor adhesion of non-woven ink, and not bright colors of patterns, etc., to achieve Improve printing efficiency and solve the effect of poor ink adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention. It should be noted that relative terms such as "first", "second" and so on may be used to describe various components, but these terms do not limit the components. These terms are only used to distinguish one component from another. For example, without departing from the scope of the present invention, a first component may be called a second component, and a second component may similarly be called a first component. The term "and / or" refers to any one or more combination of related items and described items.

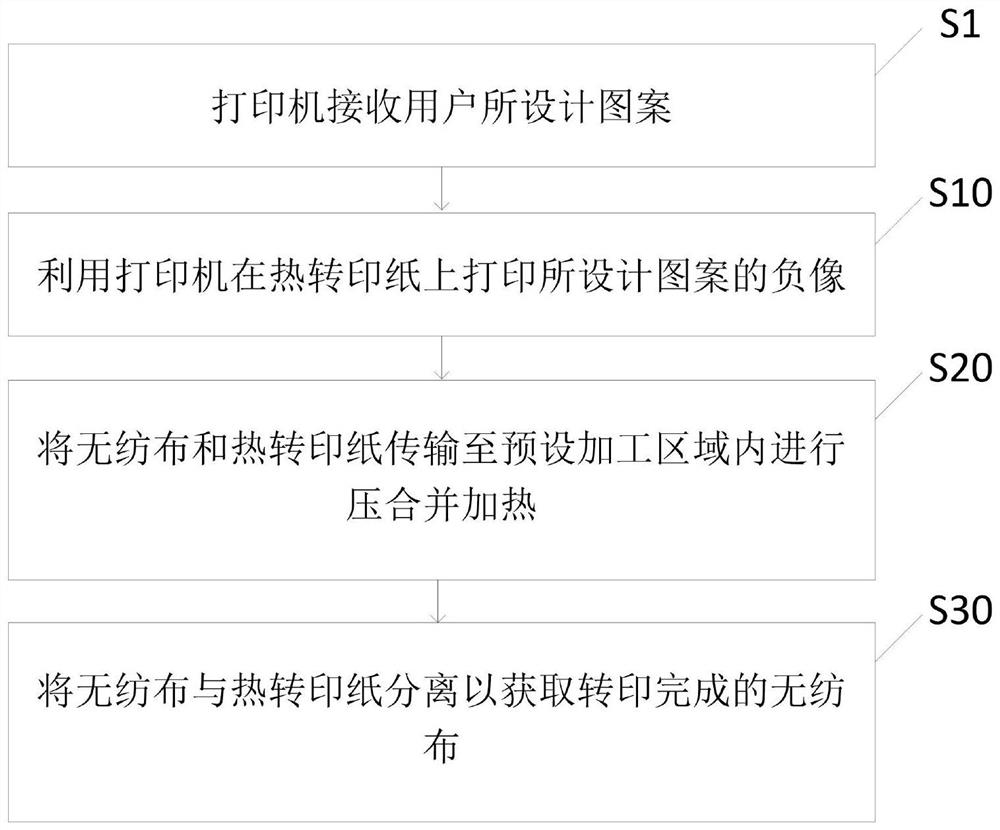

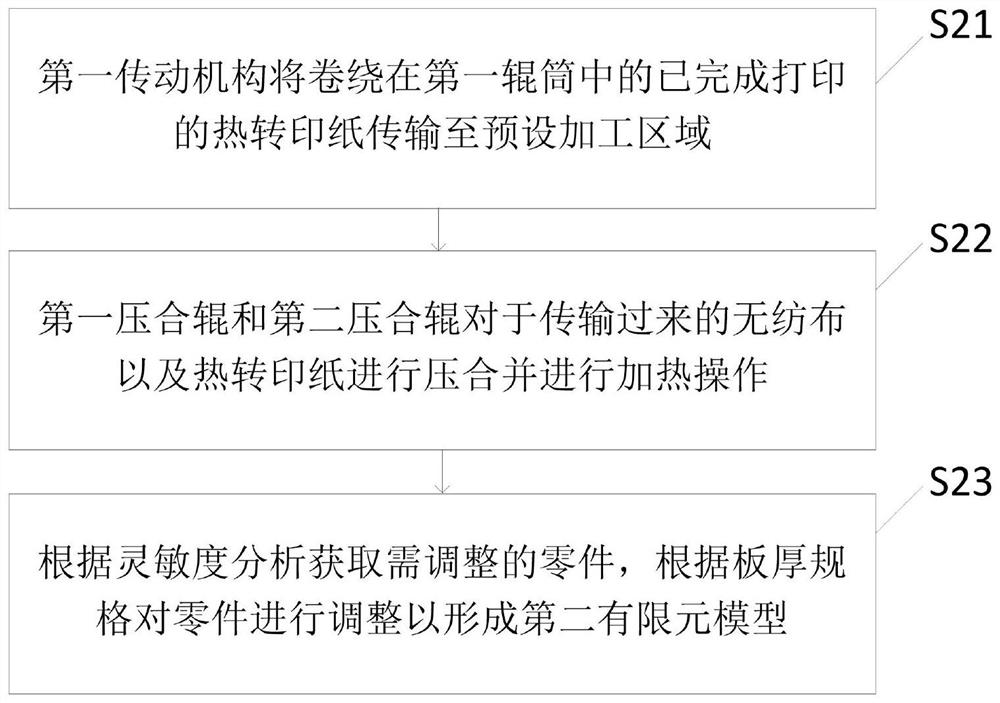

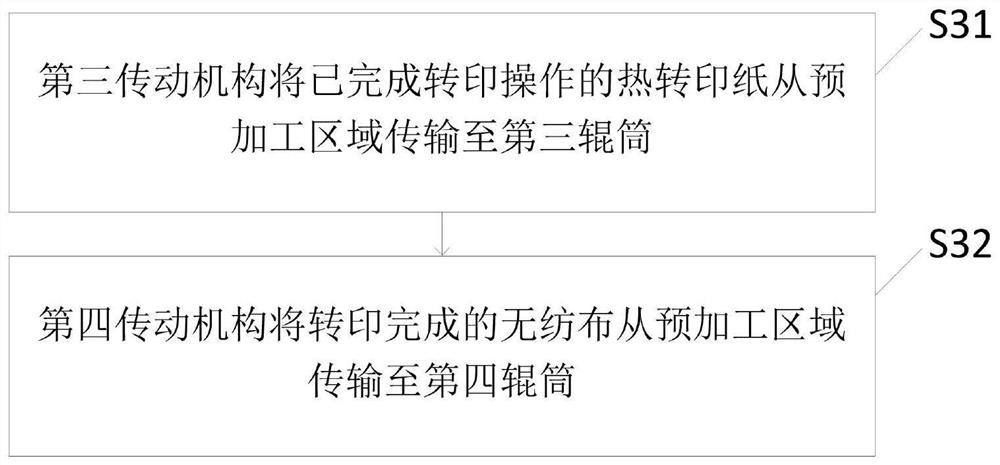

[0027] Such as figure 1 , Figure 4 as shown, figure 1 It is a schematic flow chart of the first embodiment of the thermal transfer printing method applied to non-woven fabrics in the present invention; Figure 4 It is a structural schematic diagram of the printing system corresponding to the thermal trans...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap