Vehicle steer-by-wire system based on planetary roller screw pair

A planetary roller and steer-by-wire technology, which is applied to steering mechanisms, vehicle components, mechanical steering gears, etc., can solve problems such as complex control pipelines, low steering precision, and difficulty in system integration, achieving high-efficiency, high-precision transmission, The effect of high reliability design and simple control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

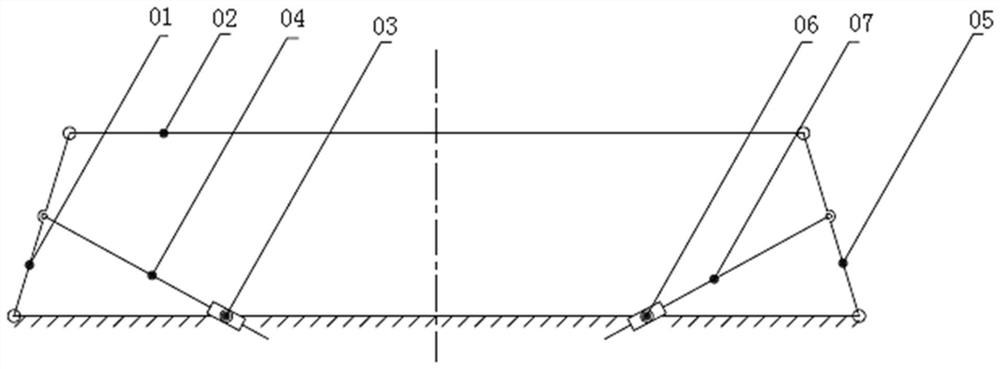

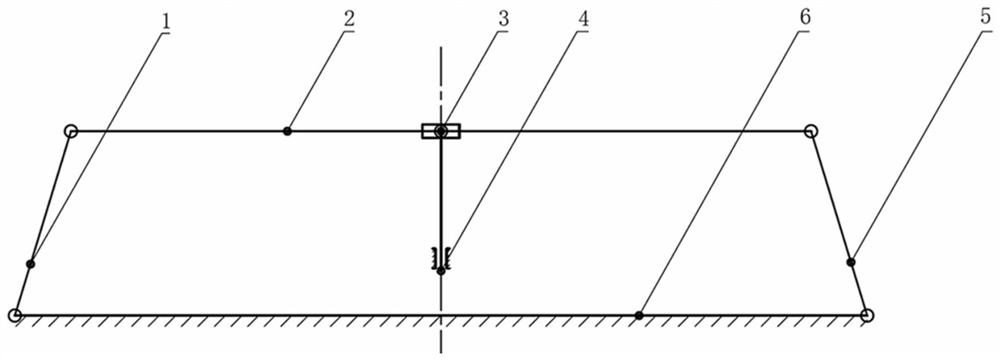

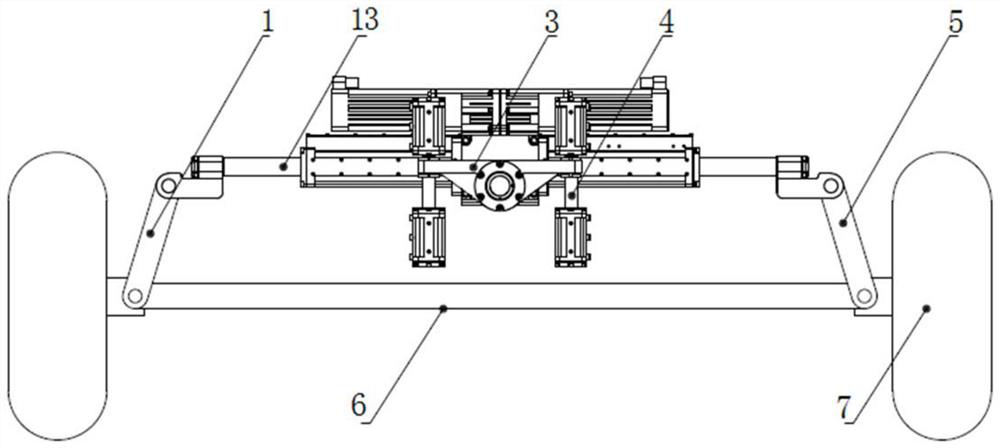

[0027] Such as figure 2 , 3 As shown, the present invention relates to a vehicle-by-wire steering system based on a planetary roller screw pair. The system includes a first mechanical movable link 1, a propulsion mechanism 2, a main transmission mechanism 3, a guide mechanism 4, and a second mechanical movable link. Connecting rod 5, base 6, front wheel 7, planetary ball screw pair and two independent power transmission devices.

[0028] A base 6 is connected between the two front wheels 7, and two sides of the base 6 are respectively movably connected to the first mechanical movable link 1 and the second mechanical movable link 5.

[0029] The propulsion mechanism 2 includes a tie rod 13 and a planetary ball screw pair. The tie rod 13 is connected with the screw shaft of the planetary ball screw pair for realizing reciprocating translation. Planetary roller screw pair is a mechanical device that converts rotational motion and linear motion into each other. As a new type of linear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com