Raw solution of fracturing fluid, acidified fracturing fluid, water-resistance-reducing and sand-carrying fracturing fluid and its preparation method

A fracturing fluid and raw fluid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of complicated construction and the inability of one agent to use multiple fracturing fluids.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

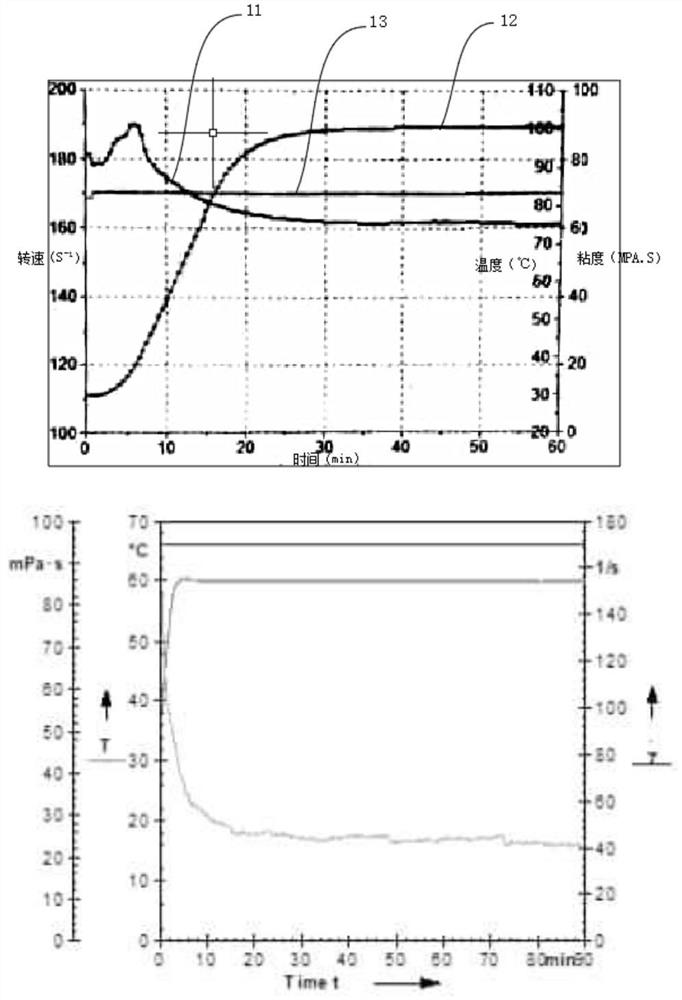

Image

Examples

Embodiment 1

[0046] Embodiment 1: Preparation of fracturing fluid stock solution

[0047] The composition of the water phase raw material of the fracturing fluid emulsion stock solution is shown in Table 1 below.

[0048] Table 1

[0049] name mass (g) Acrylamide 238 sodium acrylate 126 AMPS sodium salt 126 N,N'-Diacetonepropionamidoethylenediamine 42 DMC 14 caustic soda Appropriate amount Deionized water 854 pH 6.3-6.4 sodium formate 350mg urea 3000mg EDTA 400mg

[0050] The oil phase raw material composition of the fracturing fluid emulsion stock solution is shown in Table 2 below.

[0051] Table 2

[0052] name mass (g) No. 10 white oil 510 span80 60 Tween 60 30

[0053] Weigh the raw materials of oil phase and water phase according to the raw materials in Table 1 and Table 2 respectively, and prepare the oil phase and water phase; mix and stir according to the mass...

Embodiment 2

[0057] Embodiment 2: the preparation of fracturing fluid stoste

[0058] The composition of the aqueous phase raw material of the fracturing fluid emulsion stock solution is shown in Table 4 below.

[0059] Table 4

[0060]

[0061]

[0062] The oil phase raw material composition of the fracturing fluid emulsion stock solution is shown in Table 5 below.

[0063] table 5

[0064] name mass (g) No. 10 white oil 510 span80 60 Tween 60 30

[0065] Weigh the raw materials of the oil phase and water phase according to the raw materials in Table 4 and Table 5 respectively, and prepare the oil phase and water phase; mix and stir according to the mass ratio of oil phase and water phase of 3:7 until the viscosity is 1100±50mPa.s After feeding nitrogen with a purity of 99.99% for at least 30 minutes, lower the system temperature to 10°C, start adding composite initiators ammonium persulfate and sodium bisulfite, control the reaction temperature ...

Embodiment 3

[0069] Embodiment 3: Preparation of fracturing fluid stock solution

[0070] The composition of the water phase raw material of the fracturing fluid emulsion stock solution is shown in Table 7 below.

[0071] Table 7

[0072] name mass (g) Acrylamide 280 sodium acrylate 140 AMPS sodium salt 140 N,N'-Diacetonepropionamidoethylenediamine 56 DMC 37 caustic soda Appropriate amount Deionized water 747 pH 6.2-6.3 sodium formate 350mg urea 3000mg EDTA 400mg

[0073] The oil phase raw material composition of the fracturing fluid emulsion stock solution is shown in Table 8 below.

[0074] Table 8

[0075] name mass (g) No. 10 white oil 510 span80 60 Tween 60 30

[0076] Weigh the raw materials of oil phase and water phase according to the raw materials in Table 7 and Table 8 respectively, and prepare the oil phase and water phase; mix and stir according to the mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com