Construction method and equipment for cement concrete pavement

A technology of cement concrete and construction method, which is applied to the coagulation pavement, roads, roads and other directions of on-site paving, can solve the problems of cracking, splitting of the outer road surface and inner road surface, easy depression and deformation of the inclined road at the corners, etc., so as to reduce the The effect of splitting, reducing stress concentration and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

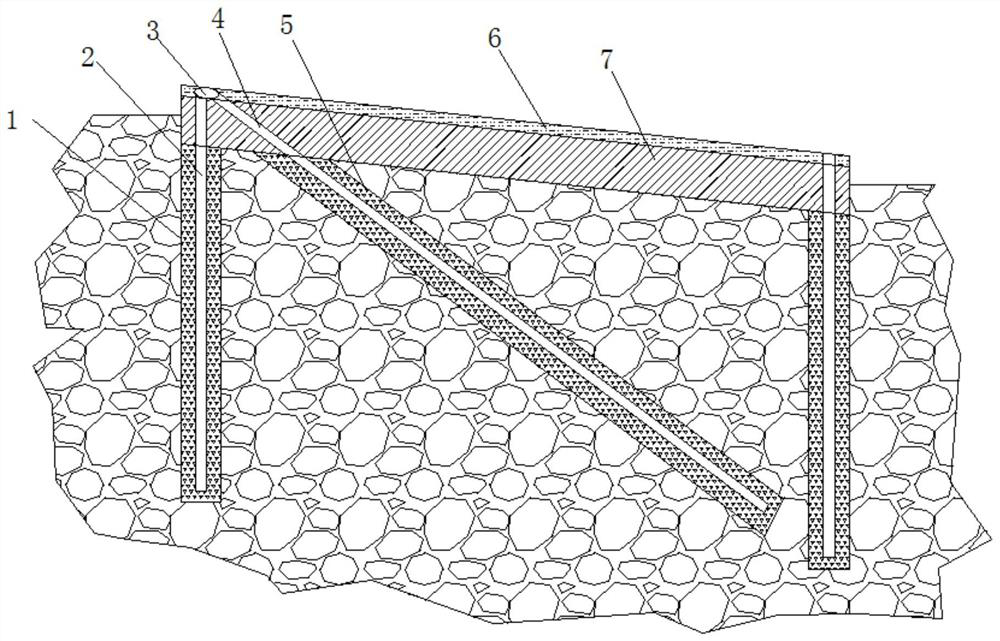

[0048] see figure 1 A schematic diagram of an implementation form of cement concrete pavement construction, the construction method includes the following steps:

[0049] Step 1. Excavate the curved roadbed, and the roadbed is inclined to the inside;

[0050] Step 2: A plurality of vertically downward first anchors 1 and a plurality of inclined downward second anchors 5 are arranged on the outer side of the roadbed, and a plurality of vertically downward anchors 5 are arranged on the inner side of the roadbed. The third anchor 9, compacting the bottom of the roadbed, laying a reinforcement frame 7 on the roadbed, and laying a reinforcement net 6 on the reinforcement frame 7, wherein, the first anchor steel rod 2 in the first anchor 1 and the reinforcement frame 7 and The outer edge 61 of the reinforcement net is fixed, and the second anchor steel rod 4 in the second anchor 5 is fixed to the outer edge 61 of the reinforcement net, that is, the first anchor steel rod 2 and the ...

Embodiment 2

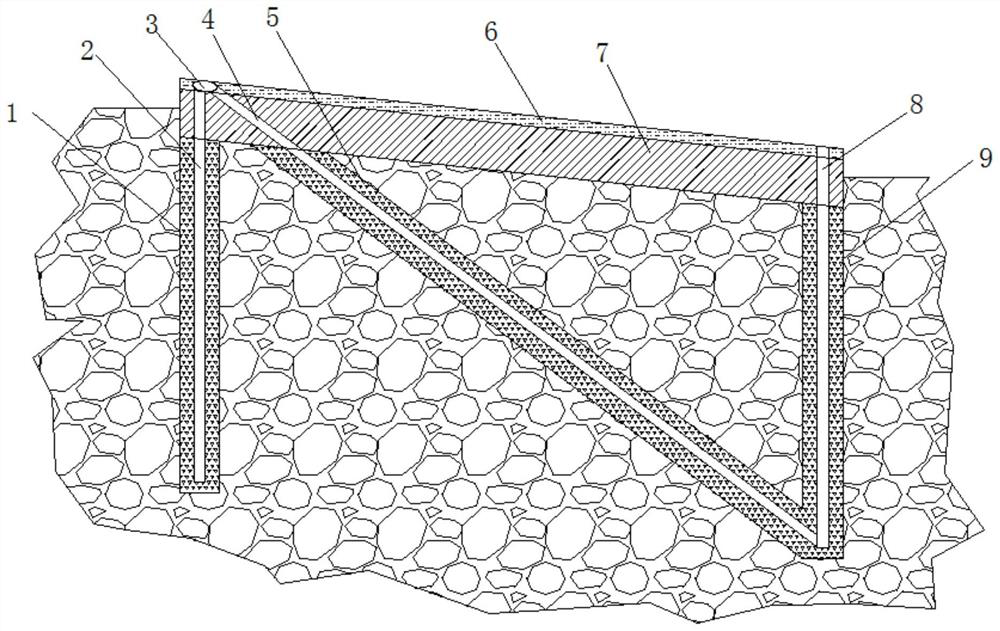

[0053] see figure 2 The schematic diagram of another implementation form of the cement concrete pavement construction, the construction method is based on the embodiment 1, requiring the second anchor 5 inclined downward and the third anchor 9 vertically downward to penetrate into the soil Fixed connection at one end. The specific setting of the first anchor 1 is as follows: on the outer side of the subgrade, drill holes vertically through drilling equipment, pour cement concrete into the holes until the cement concrete fills the holes, and then insert steel rods into the holes, And vibrate with a vibrator until it is dry; the specific setting of the second anchor 5 and the third anchor 9 is as follows: on the outer side of the subgrade, drill holes obliquely through drilling equipment to obtain inclined holes for setting the first Two anchors 5; on the inner side of the subgrade, drill vertically through drilling equipment to obtain a vertical hole for setting the third anc...

Embodiment 3

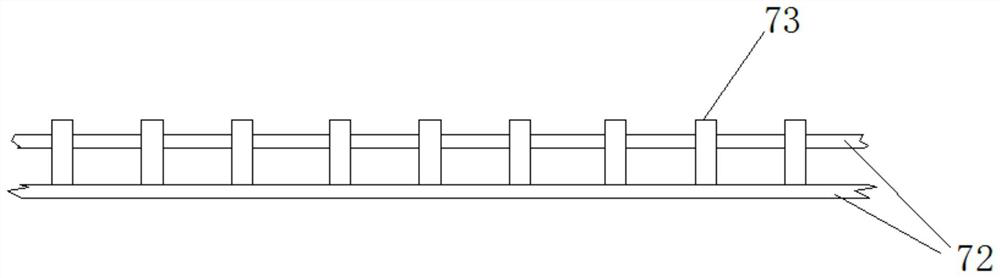

[0055] see Figure 3-4 The schematic diagram of the reinforcement structure, construction method On the basis of embodiments 1 and 2, the reinforcement structure inner side 72 and the outer side of the upper surface of the reinforcement structure 7 are provided with a plurality of protrusions 73, and the reinforcing mesh 6 A groove matching the protrusion 73 is provided on the side. This can make the connection between the upper layer and the lower layer of the pavement closer and reduce road damage such as cracking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com