Air intake service pipe assembly

An introduction pipe and assembly technology, which is applied to the field of intake introduction pipe assembly, can solve the problems of high cost, large investment, complex water retaining structure, etc., and achieve the effects of low cost, small airflow resistance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

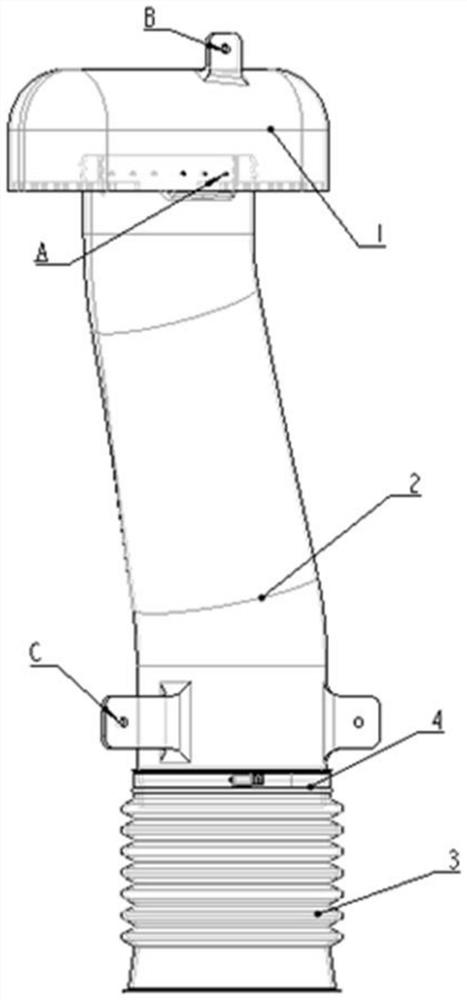

[0013] Such as figure 1 As shown, a kind of intake pipe assembly of the present invention includes a rainproof cover 1, an intake introduction pipe 2 and a bellows 3, the top of the rainproof cover 1 is a long semicircular curved surface, and rainwater flows down along the smooth curved surface, There is a grid-shaped baffle at the lower part; the cross section of the air inlet pipe 2 is oval, and there are bosses A on both sides of the upper part, which are inserted into the rainproof cover 1, and the boss A is connected with both sides of the rainproof cover 1 by rivets; The lower part of the pipe 2 and the corrugated pipe 3 are connected by a band 4 . The invention has simple structure and small airflow resistance; rainwater and leaves will not be sucked into the intake pipe; the cost is low, and the profit of the whole vehicle is improved....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com