Composite brightness enhancement film back coating surface structure and manufacturing method

A technology of surface structure and enhancement film, which is applied in optics, optical components, nonlinear optics, etc., can solve problems such as structural pits on the back coating surface, and achieve the effect of improving shielding, increasing the value of enhancement gain, and scientific and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

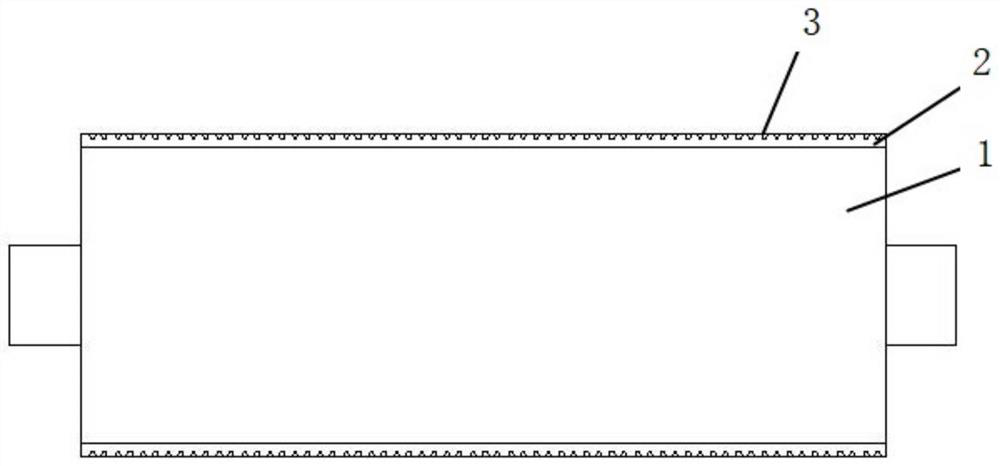

[0033] This embodiment is a back-coating surface structure of a composite light-enhancing film, including a base material, and the base material has a pair of opposite surfaces, which are respectively a light-incoming surface and a back-coating surface. The back coating surface is a rough prism surface, which is processed by an improved forming roller. The rough prism surface has multiple convex points, and the surface of the convex points is reflective. The improved forming roll includes a base roll 1 and a nickel-phosphorus layer 2 electroplated on its outside. The surface of the base roll 1 is flattened before electroplating, and thread cutting and engraving is performed on the nickel-phosphorus layer 2 with a diamond tool after electroplating. , the cutting depth of the diamond tool is 2-5um, the cutting frequency is 15000-20000HZ, the cutting depth and the cutting frequency are both random; the surface of the nickel phosphorus layer 2 has a micro concave structure 3 after ...

Embodiment 2

[0046] This embodiment is basically the same as Embodiment 1, except that the nickel-phosphorus layer has a thickness of 230mm and a hardness of 572HB.

[0047] The lightening gains of this embodiment and the common sandblasting structure under different hazes are shown in the following table:

[0048] Grace gain Haze 10% Haze 15% Haze 20% Haze 30% Ordinary sandblasting structure 100% 100% 100% 100% The structure of this embodiment 102.4% 102.3% 103% 102.2%

[0049] On the premise of the same shielding performance, the structural design of this embodiment can increase the brightness enhancement gain value of the brightness enhancement film by 2-3%.

Embodiment 3

[0051] This embodiment is basically the same as Embodiment 1, except that the thickness of the nickel-phosphorus layer is 250mm, and the hardness is 574HB.

[0052] The lightening gains of this embodiment and the common sandblasting structure under different hazes are shown in the following table:

[0053] Grace gain Haze 10% Haze 15% Haze 20% Haze 30% Ordinary sandblasting structure 100% 100% 100% 100% The structure of this embodiment 102.3% 103% 102.5% 102.1%

[0054] On the premise of the same shielding performance, the structural design of this embodiment can increase the brightness enhancement gain value of the brightness enhancement film by 2-3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com