Plate bending equipment

A technology of bending and plate body, which is applied in the field of plate processing, can solve the problems of reducing processing efficiency, affecting the appearance, reducing the thickness of the plate body, etc., and achieves the effect of improving service life, long service life and small sliding distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

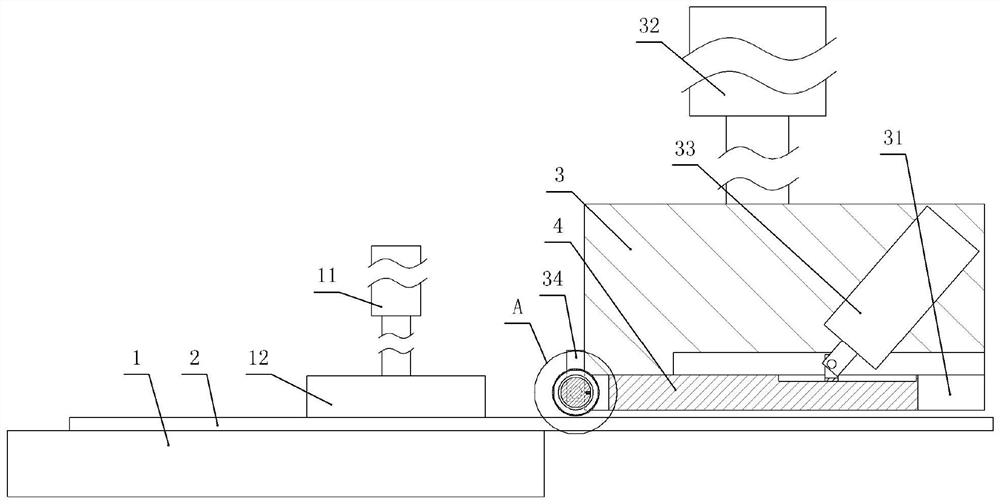

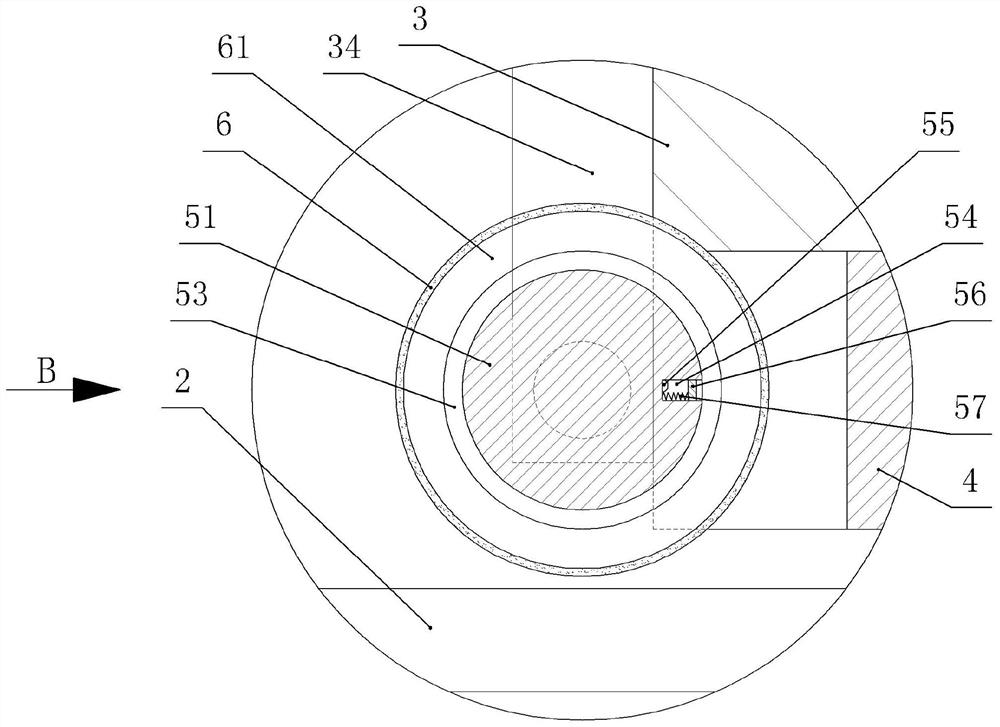

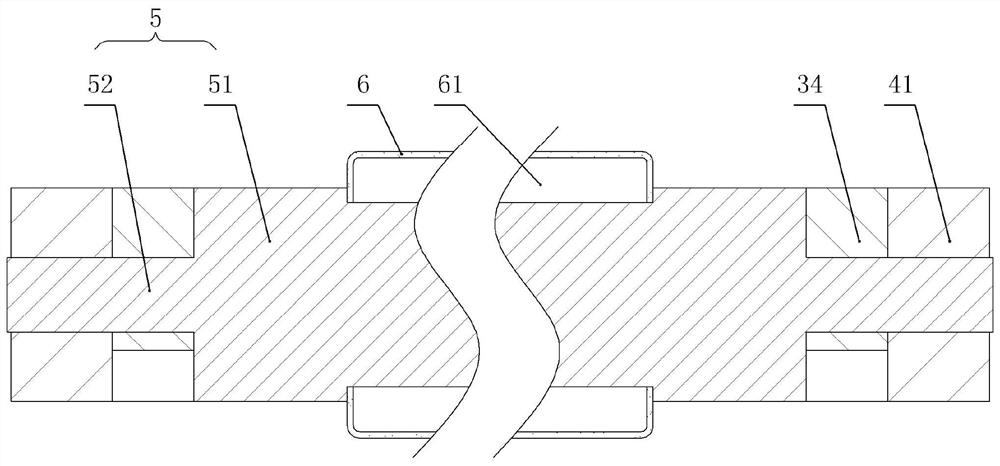

[0034] Plate bending equipment, such as figure 1 and figure 2 As shown, it includes frame, workbench 1, pressing unit, punch and first drive member 32, workbench 1 is welded on the frame horizontally, and press unit, punch and first drive member 32 are all located on the workbench 1, the compression unit includes a compression hydraulic cylinder 11 and a compression block 12, the compression hydraulic cylinder 11 is fixed on the frame by bolts and the push rod of the compression hydraulic cylinder 11 faces downward, and the compression block 12 is welded on the The push rod lower end of hydraulic cylinder 11.

[0035] The first driving part 32 and the vertical projection of the punch are all located on the right side of the workbench 1. The first driving part 32 in this embodiment adopts a hydraulic cylinder, and the first driving part 32 is fixed on the frame by bolts. The push rod of the first driving member 32 faces downward. The punch includes a main body 3 and a bendi...

Embodiment 2

[0043] On the basis of Example 1, such as Figure 5 As shown, the bottom of the bent plate 4 in this embodiment is glued with a rubber layer made of rubber. In addition, the front end of the main body 3 is vertically welded with a plate-shaped angle measuring device 7, the lower end of the angle measuring device 7 is lower than the main body 3 and the angle measuring device 7 is located on the front side of the bending plate 4, and the angle measuring device 7 is provided with several measuring bends. The scale line of the rotation angle of the folding plate 4.

[0044] In this embodiment, after the bending plate 4 is rotated, the bending angle of the bending plate 4 is the same as the bending angle of the plate body 2 because the bending plate 4 sticks to the bent part of the plate body 2 . In this embodiment, when the bending plate 4 is rotated, when the bending plate 4 is aligned with the scale on the angle measuring device 7, the scale on the angle measuring device 7 is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com