Multifunctional crochet hook knitting machine with transmission clutch device

A clutch device and knitting machine technology, which is applied in the field of crochet knitting machines, can solve problems such as potential safety hazards, and achieve the effects of saving costs, fast separation, and improving product quality and production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

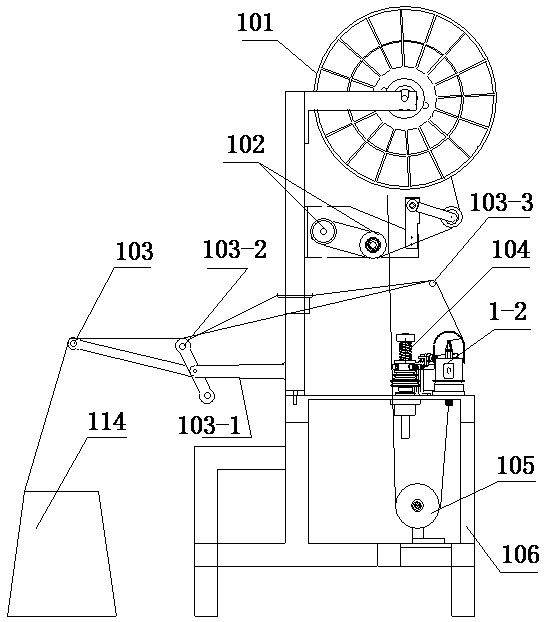

[0051] Embodiment 1: The crochet knitting machine includes: a wire take-up reel 101, a wire take-up sheave 102, a wire passing shaft 103, a passing wheel 105, a frame 106, a transmission 107, a motor 108, a hook clutch device, a transmission device and a platform 20;

[0052] There is a platform 20 in the middle position of frame 106, and crochet hook assembly 1-2 and transmission device are installed on platform 20, passing wheel 105 is installed in the frame 106 below platform 20, the frame 106 above platform 20 A take-up reel 101 and a take-up sheave 102 are installed on the top of the platform, a spool support 103-1 is installed on the frame 106 at the platform 20 rear, and a spool 103 is connected to the front end of the spool support 103-1. The middle position of the bracket 103 - 1 is connected with a thread passing middle shaft 103 - 2 , and above the clutch device 104 is connected with a thread passing front shaft 103 - 3 .

[0053] A crochet hook assembly 1-2 and a c...

Embodiment 2

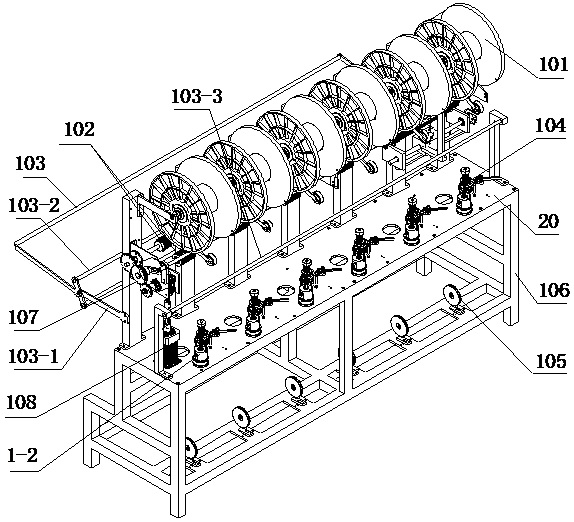

[0072] Embodiment 2: The crochet knitting machine includes: a wire take-up reel 101, a wire take-up sheave 102, a wire passing shaft 103, a passing wheel 105, a frame 106, a transmission 107, a motor 108, a hook clutch device, a transmission device and a platform 20;

[0073] There is a platform 20 in the middle position of frame 106, and crochet hook assembly 1-2 and transmission device are installed on platform 20, passing wheel 105 is installed in the frame 106 below platform 20, the frame 106 above platform 20 A take-up reel 101 and a take-up sheave 102 are installed on the top of the platform, a spool support 103-1 is installed on the frame 106 at the platform 20 rear, and a spool 103 is connected to the front end of the spool support 103-1. The middle position of the bracket 103 - 1 is connected with a thread passing middle shaft 103 - 2 , and above the clutch device 104 is connected with a thread passing front shaft 103 - 3 .

[0074] A crochet hook assembly 1-2 and a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com