A tod upper cover shock-isolation conversion structure

A conversion structure and seismic isolation technology, applied in the field of TOD, can solve the problems that the seismic effect of the upper structure cannot be reduced, the impact cannot be reduced, and the impact of the upper structure, etc., to achieve the effect of increasing the aspect ratio limit, increasing the height of the structure, and increasing the usable area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

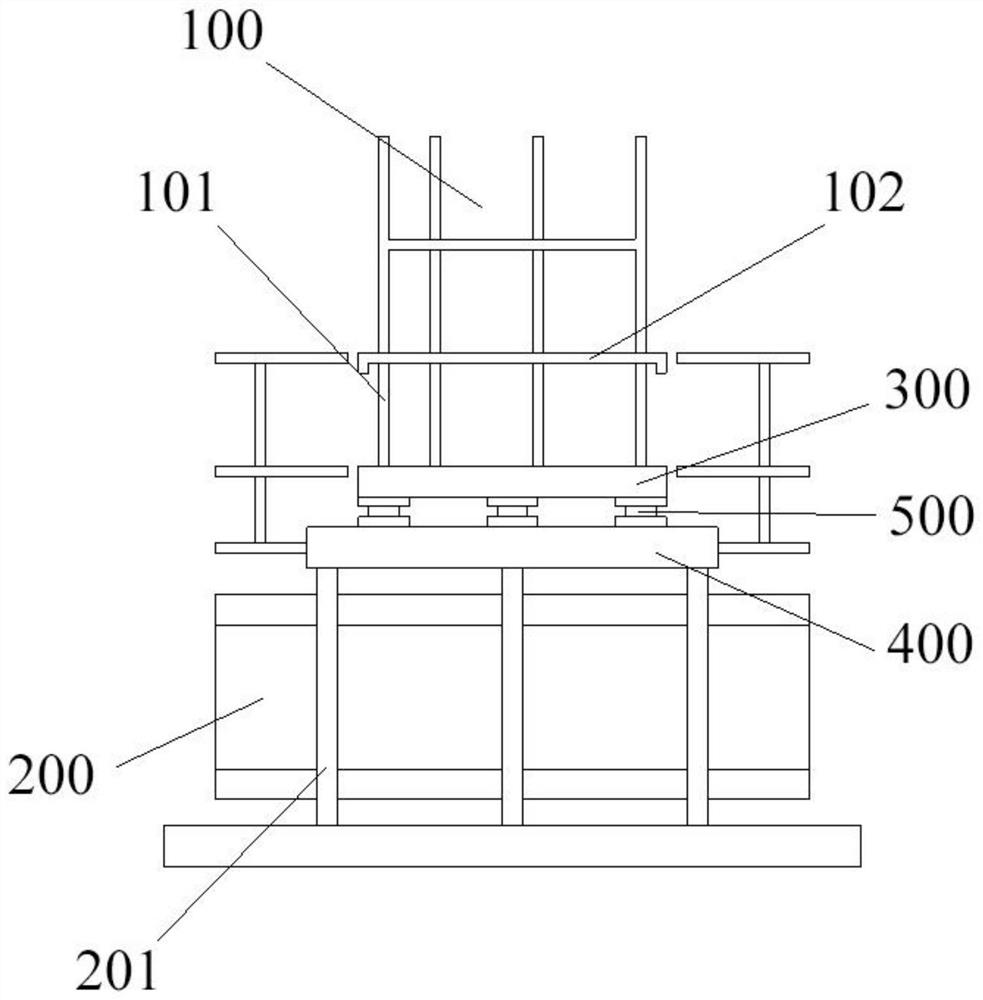

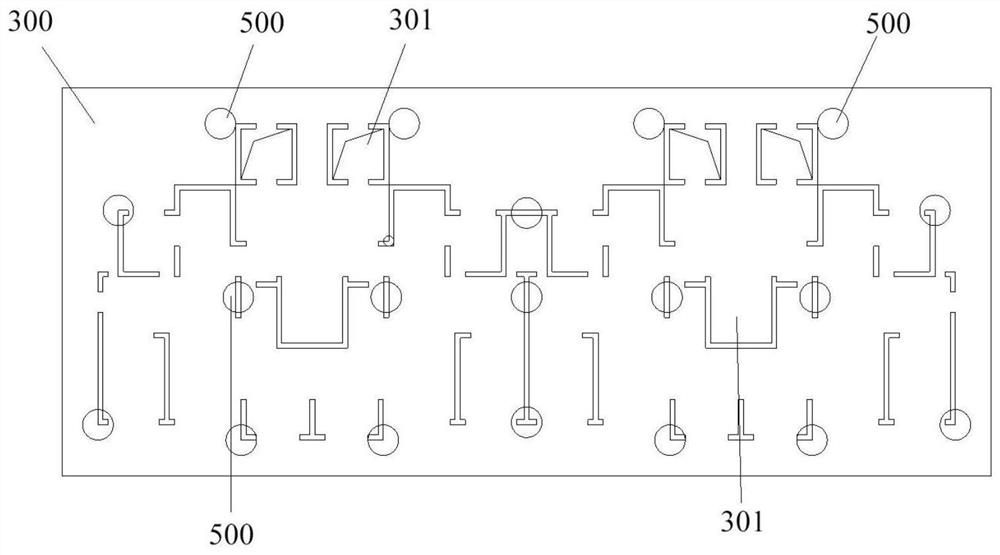

[0057] Such as figure 2 As shown, a TOD upper cover shock-isolation transfer structure includes an upper transfer layer 300, a lower transfer layer 400 and several shock-isolation buffer supports 500, and several shock-isolation buffer supports 500 are arranged on the upper transfer layer 300 and the lower transfer layer Between 400.

[0058] The upper conversion layer 300 is arranged at the lower part of the superstructure 100, and the upper surface of the upper conversion layer 300 is connected with several first support structures 101 of the superstructure 100. The first support structures 101 can be support columns or shear walls.

[0059] Wherein, the superstructure 100 may be buildings such as residences, shopping malls, and hotels.

[0060] The first distance between the upper surface of the upper conversion level 300 and the lowermost floor 102 of the superstructure 100 is at least 0.5 m.

[0061]The lower conversion layer 400 is disposed on the upper part of the lo...

Embodiment 2

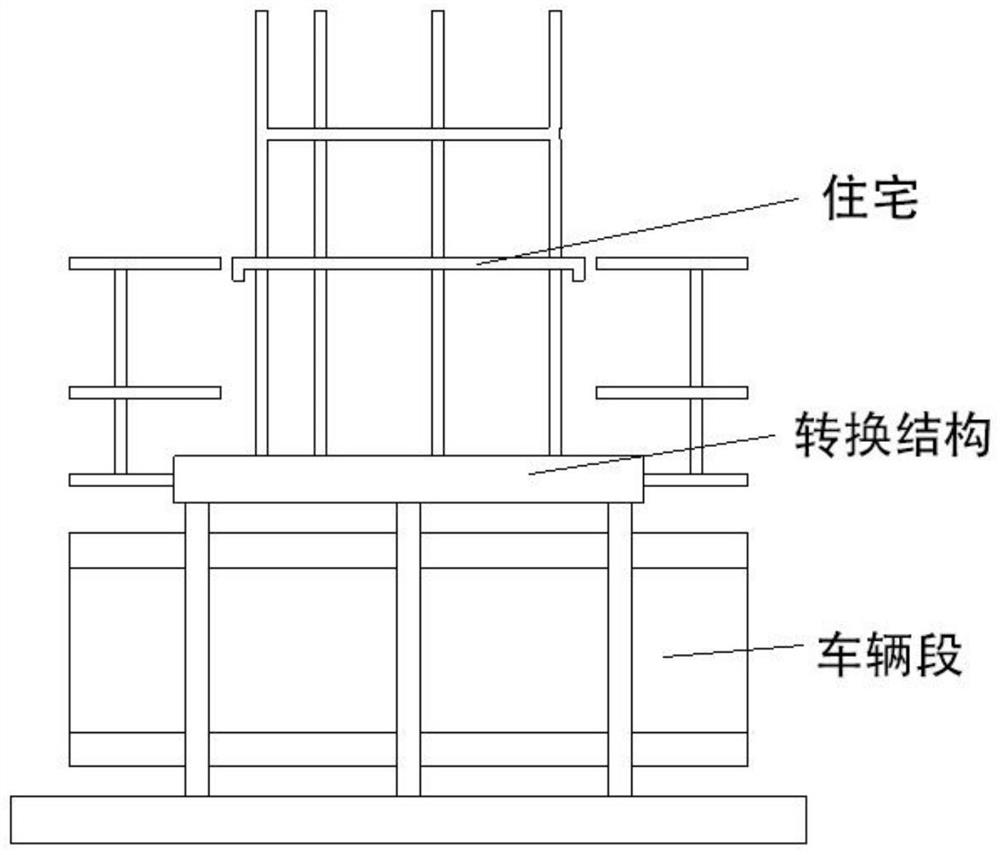

[0097] In a certain TOD project in Shanghai, the conversion structure adopted in the initial design is a hard conversion structure (refer to figure 1), that is, the down conversion layer 400 is directly connected to the superstructure 100 and the substructure 200 respectively, and the thickness of the down conversion layer 400 is at least 2500mm. Due to the irregular structure of the substructure 200 , the lower conversion layer 400 below part of the wall of the superstructure 100 cannot meet the force requirements, and structural reinforcement is required before implementation. Since the substructure 200 of the TOD project is a subway depot, and the operation of the subway cannot be stopped, reinforcement construction cannot be performed on the substructure 200 . In addition, due to the hard transfer structure, there is no seismic isolation effect, so that the seismic force of the superstructure 100 will not be reduced. In addition, there is a huge difference between the flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com