Heat-resistant filter layer, filter body, and its production method

A technology of filter layer and filter body, which is applied in the direction of separation method, filter separation, membrane filter, etc., can solve the problems of lack of position or space, and achieve the effect of avoiding vibration or shaking, avoiding loosening phenomenon, and firm combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

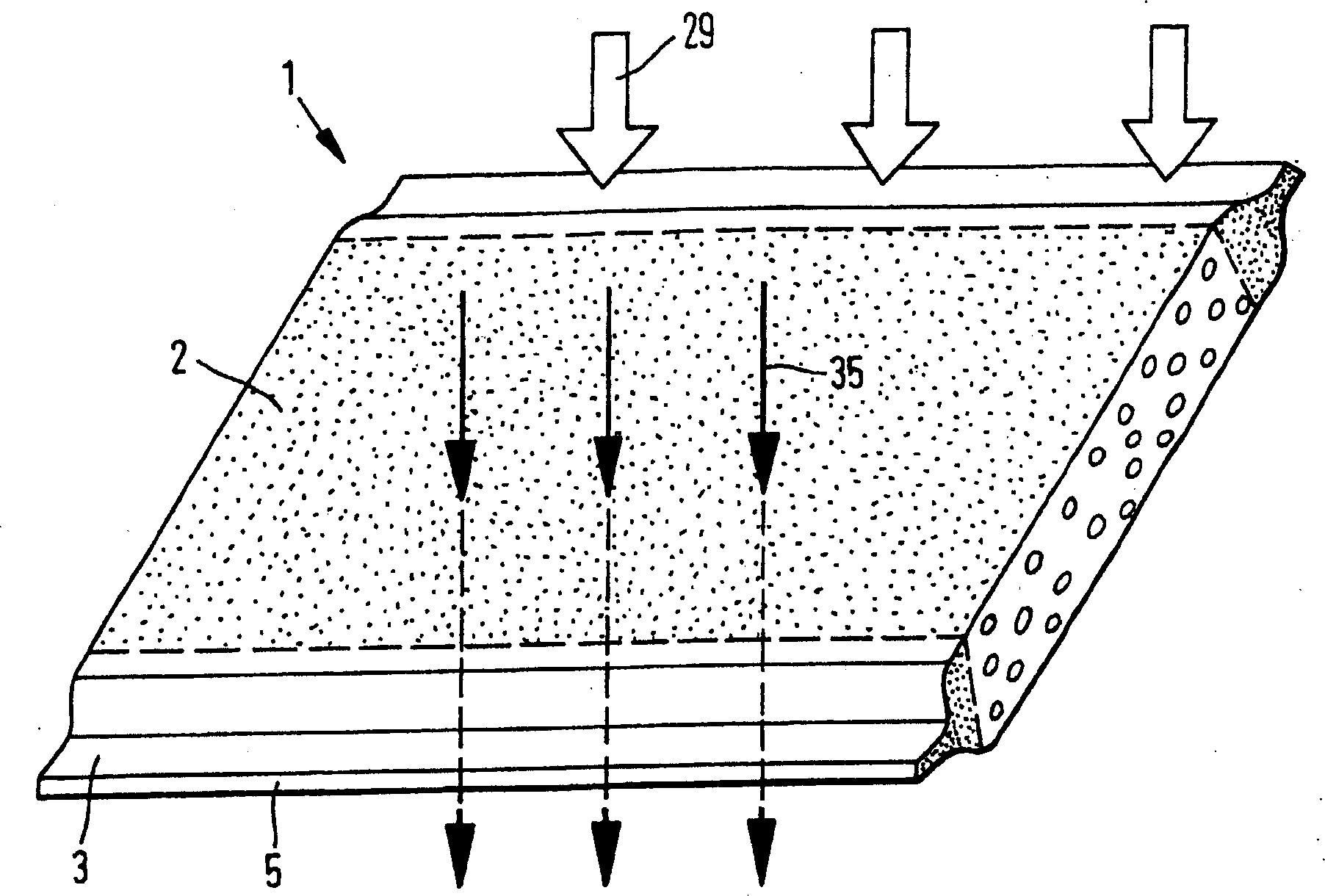

[0057] figure 1 An embodiment of a filter layer 1 according to the invention is shown schematically in perspective, which is permeable for a fluid in at least one filter segment 2 (indicated by flow direction 35 ). The filter layer 1 is made at least partially of a porous material (see filter segment 2 indicated by dashed lines) and has two edge regions 3 adjacent opposite edges 5 . The edge regions 3 are compressed by a pressing force 29 (indicated by arrows), so that they have a reduced layer thickness 4 compared to the filter section 2 . The compression is symbolized by pores or cavities shown in the sectional view, which are shown to be significantly smaller in the edge region 3 than in the filter section 2 .

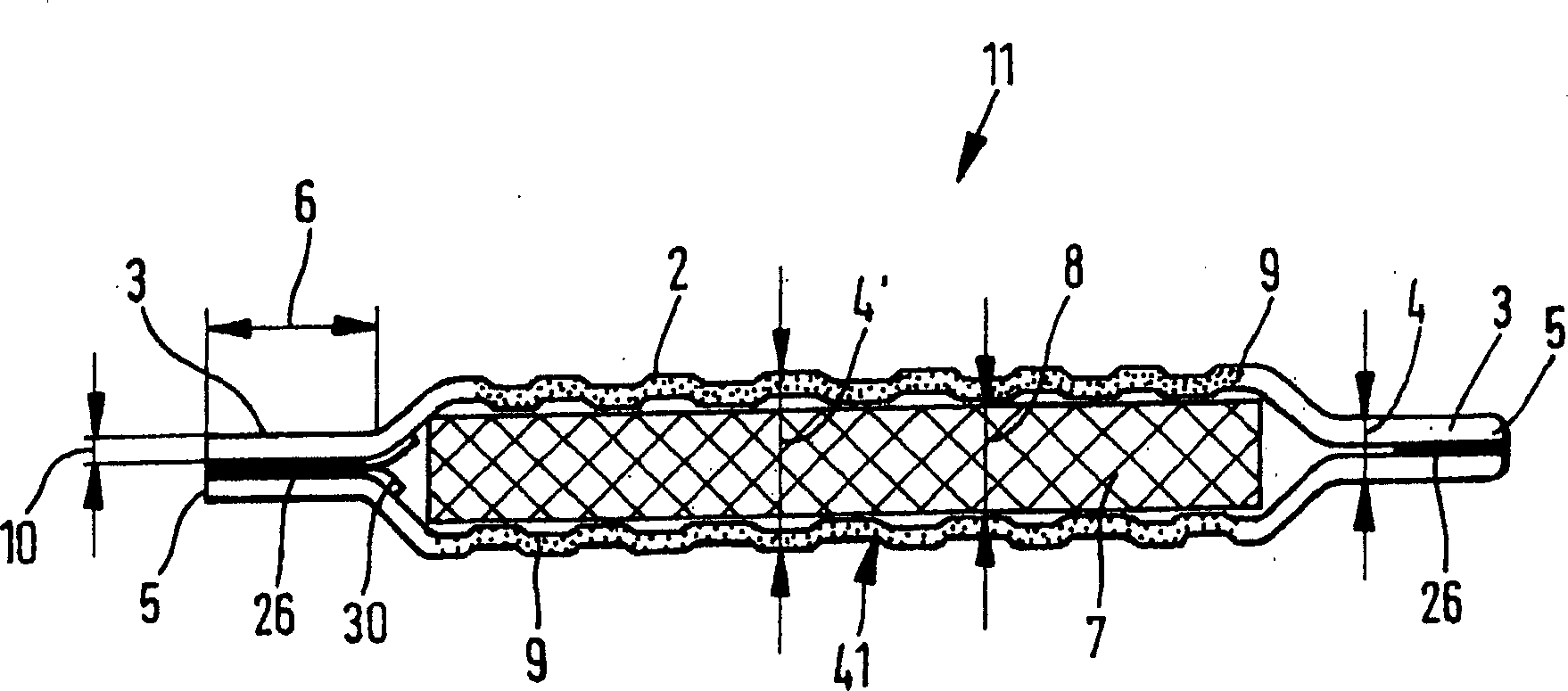

[0058] figure 2 A further embodiment of a filter layer 1 designed as a sandwich structure 11 is schematically shown in cross-section, wherein the filter layer has two metal layers 9 forming an outer shell around the fiber layer 7 . The metal layers 9 each have ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com