Method and application of a multi-directional truss-frame-core tube combination super high-rise structure with O-shaped chamfered edges

A core tube and beveled edge technology, applied in special structures, building components, building structures, etc., can solve the problems of complex node connection structure, complex component assembly, etc., to ensure bearing performance, clear force transmission, and high structural height. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

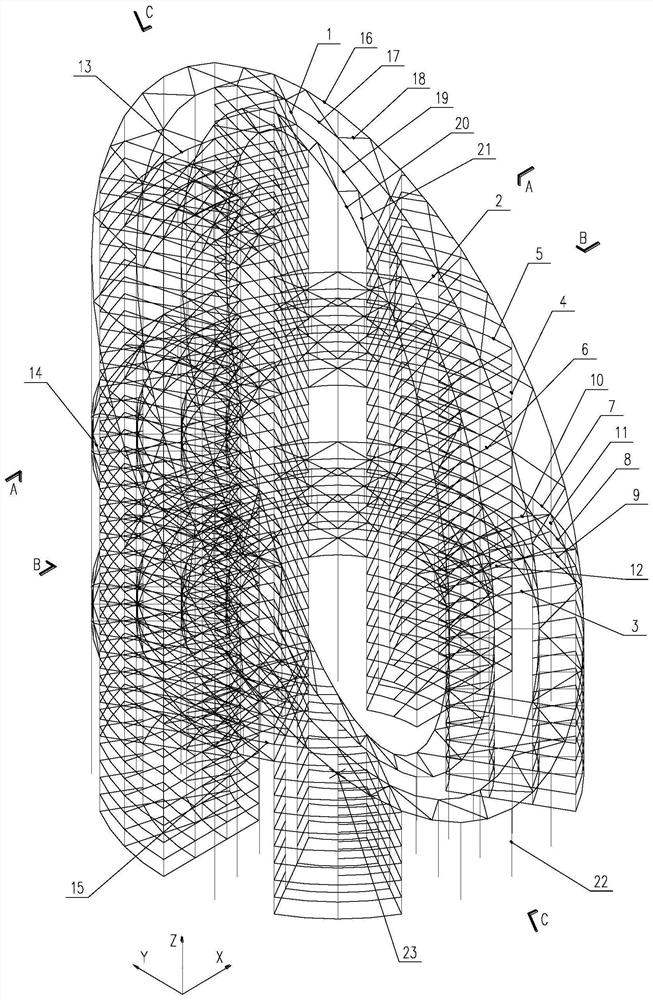

[0079] Such as Figures 1a-1f as well as Figure 2-Figure 4 As shown, the multi-directional truss-frame-core tube combination super high-rise structure of the O-shaped chamfered edge includes a supporting core tube, a floor frame, a multi-directional large-span multi-layer truss, a chamfered edge boundary truss, and a non-floor frame. The supporting core tube ( Figure 1b ) is the main component of vertical lateral force resistance, which is composed of several groups of small core tubes arranged uniformly, symmetrically and dispersedly along the circumferential direction of the plane. Figure 1c ) are located in the vicinity of the periphery of each small core tube, combined with the small core tube to form a local monomer structure, and together serve as the end vertical support structure of the multi-directional large-span multi-layer truss; the multi-directional large-span multi-layer truss ( Figure 1d ) includes the arrangement of planes and facades in different orient...

Embodiment 2

[0096] Such as Figure 11 As shown, the composition method of the multi-directional truss-frame-core tube composite super high-rise structure of the O-shaped chamfered edge comprises the following steps:

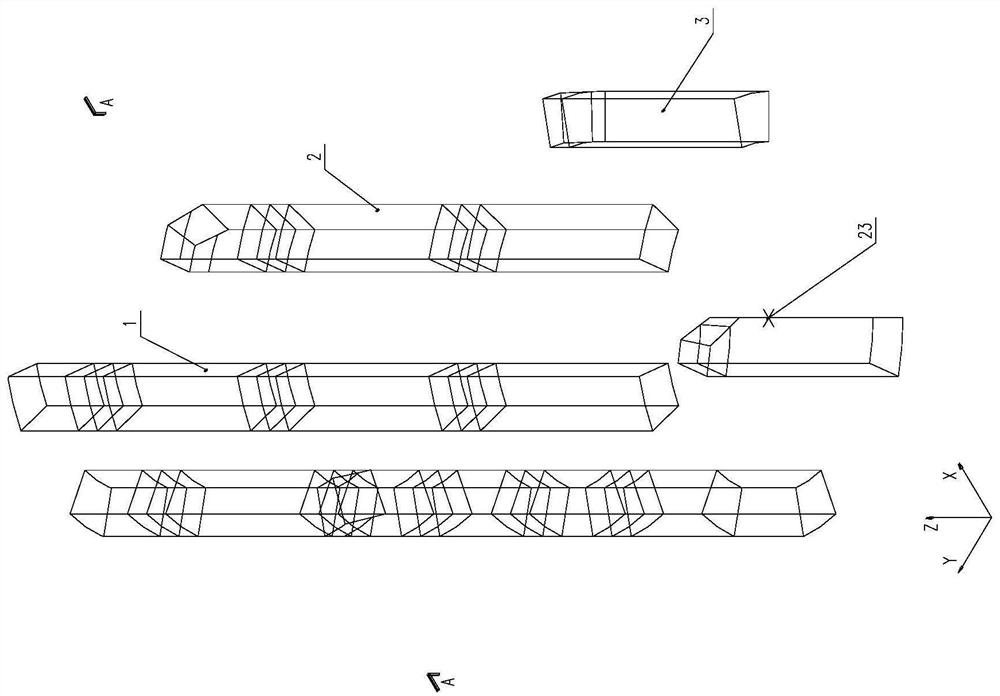

[0097] S1. The high zone tube 1 supporting the core tube, the middle zone tube 2 supporting the core tube, and the low zone tube 3 supporting the core tube form the main component of vertical lateral force resistance, which is distributed, evenly and symmetrically arranged around the central positioning point 23 ;

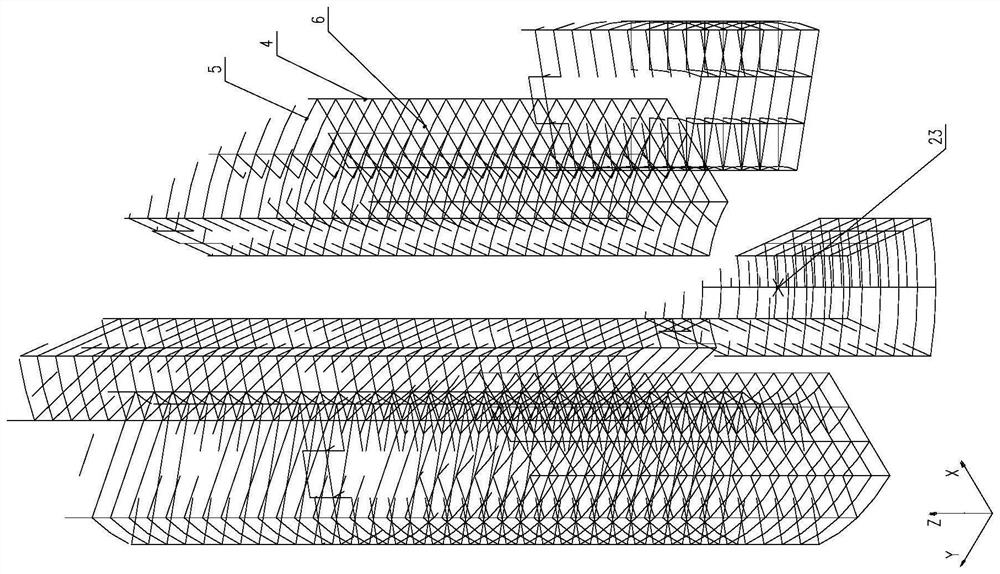

[0098] S2. The frame column 4 of the floor frame supporting the periphery of the core tube, the circumferential frame beam 5 of the floor frame, and the radial frame beam 6 of the floor frame form a floor frame, and together with the supporting core tube, constitute a vertical lateral force-resistant structural system ;

[0099] S3. The upper chord of the hoop truss of the long-span multi-layer truss 7, the middle chord of the hoop truss of the long-span multi-...

Embodiment 3

[0106] The present invention also provides an O-shaped chamfered multi-directional truss-frame-core tube combined super high-rise structure in the O-shaped chamfered building facade boundary shape and plane, facade multi-region multi-directional local large space function Truss-frame-core tube combination super high-rise structural system design and application in load bearing, the super high-rise refers to high-rise public buildings with a height of not less than 100 meters.

[0107] The multi-directional truss-frame-core tube composite super high-rise structure of the O-shaped chamfered edge of this embodiment is based on the combined super high-rise overall structural form of multiple groups of small core tubes and surrounding landing frames, and a multi-directional large-span multi-layer truss structure. The boundary and local large-scale space structure are processed through the space boundary trusses and non-floor frames to form an overall stress mode, which can realize t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com