Steel reinforcement polygonal steel pipe concrete column

A CFST column and polygon technology, applied in columns, pier columns, pillars, etc., can solve the problems of underutilized material strength, weak concrete restraint, complicated concrete column structure, etc., and achieve superior seismic performance and sufficient strength. Leverage and enhance the effect of collaborative work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

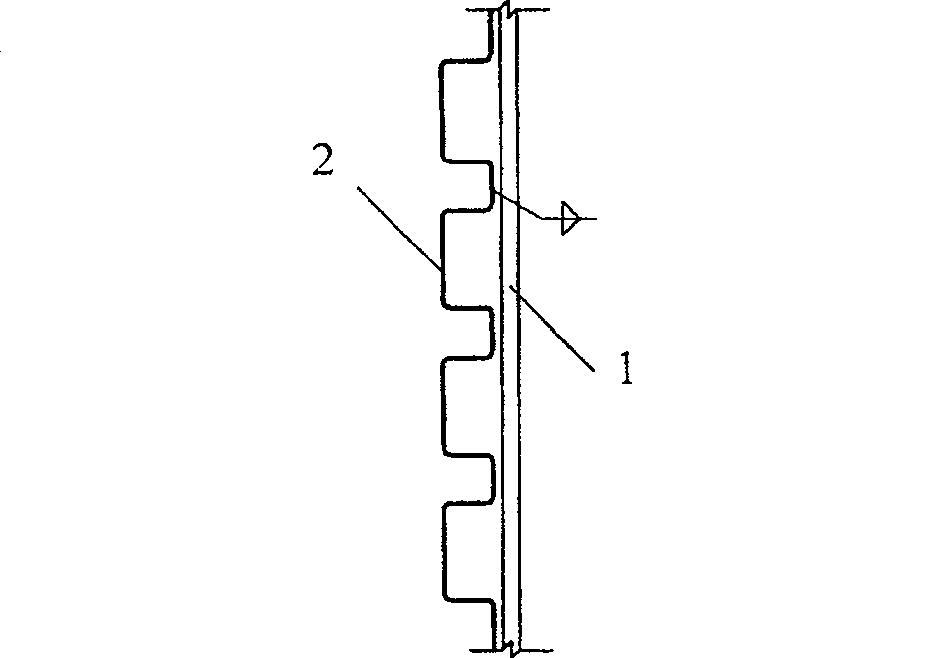

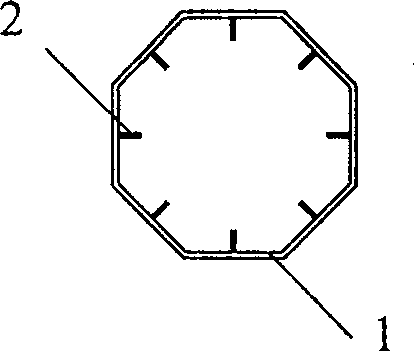

[0012] Specific implementation mode one: the following combination Image 6 , Figure 7 with Figure 8 Describe this embodiment in detail, this embodiment is made up of square, rectangular or polygonal steel pipe 1, reinforcing bar stiffener 2 and filling concrete 4, the steel pipe that fills with filling concrete 4 is square, rectangular or polygonal steel pipe 1, in square, rectangular Or the inner wall of the polygonal steel pipe 1 is welded with reinforcing ribs 2 along the axis direction of the square, rectangular or polygonal steel pipe 1 . It also includes tension reinforcement bars 3 which are arranged between reinforcement ribs 2 . The square, rectangular or polygonal steel pipe 1 of the present invention is made of Q235 steel, Q345 steel, Q390 steel or Q420 steel; the ratio of the length of the square, rectangular or polygonal steel pipe 1 to the minimum section width is ≤30. The steel stiffener 2 and the tensioned steel bar 3 can be formed by cold-bending of HPB2...

specific Embodiment approach 2

[0013] Specific implementation mode two: the following combination figure 1 with figure 2 This embodiment is specifically described. In this embodiment, a reasonable steel bar type and diameter are determined according to parameters such as square, rectangular or polygonal steel pipe cross-sectional shape, steel plate wall thickness, etc., and the steel bar stiffener 2 is used along the axis of the steel pipe 1 by using single-sided or double-sided fillet welds. Welded on the inner wall of the steel plate of the steel pipe 1, the length of the reinforcing rib 2 is equal to that of the square, rectangular or polygonal steel pipe 1, and the other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

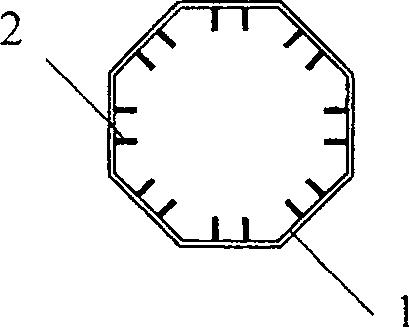

[0014] Specific implementation mode three: the following combination image 3 Describe this embodiment in detail, the steel plate width of square, rectangular or polygonal steel pipe 1 of this embodiment is big, add reinforcement rib 2 on the inner side of each steel plate, to reduce the width-to-thickness ratio of steel plate, strengthen the synergy between steel pipe 1 and inner concrete 4 Work, other composition and connection relations are the same as the specific embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com