A prefabricated bamboo-aerated concrete composite structure and its manufacturing method

A technology of aerated concrete and aerated concrete slabs, applied in truss-type structures, building structures, buildings, etc., can solve the problems of insufficient flexural rigidity, insufficient bearing capacity, and low strength utilization rate, and achieve high bearing capacity, High tensile strength and good seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

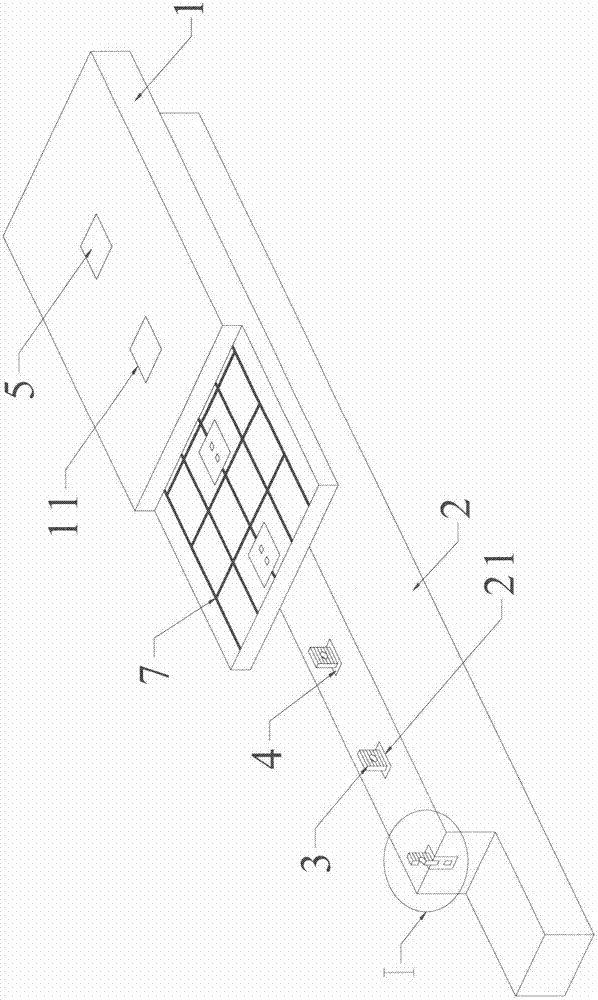

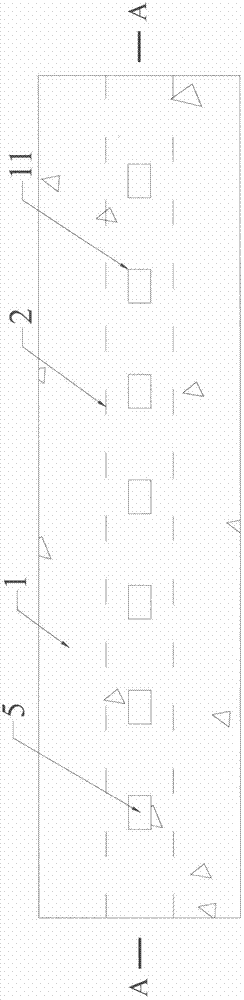

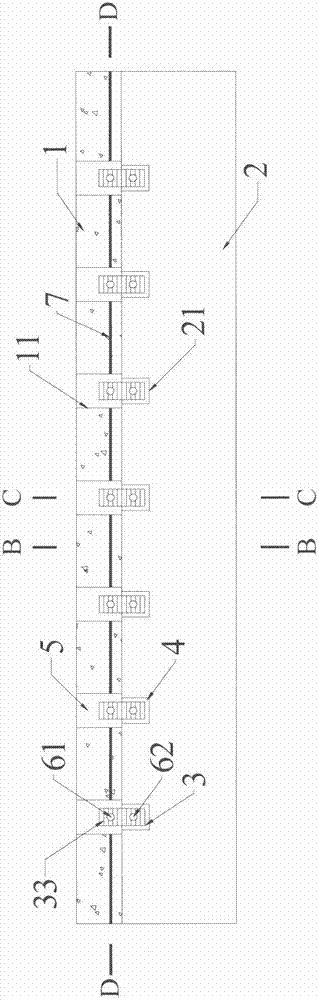

[0043] Such as Figure 1 to Figure 10 , the present invention provides an assembled bamboo-air-entrained concrete composite structure, which is composed of prefabricated aerated concrete slab 1, bamboo beam 2, perforated metal plate 3, adhesive glue 4 and hole-filling material 5, and is characterized in that the prefabricated The aerated concrete slab 1 is located above the bamboo girder 2, the axes of the two are parallel and the length is the same, the bottom surface of the former is closely connected with the top surface of the latter, and the prefabricated aerated concrete slab 1 and the bamboo girder 2 are arranged at intervals along the length direction. Reserved holes 11 and reserved seams 21, the positions of the reserved...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com