A metal buckling-restrained support of post-mounted casing and its construction method

A technology of buckling restraint and construction method, which is applied in the direction of building components, earthquake resistance, etc., can solve the problems of high requirements for restraint sleeves, easy occurrence of high-order buckling, and short working section, so as to improve collapse resistance and large-section bending resistance Rigidity, effect of ensuring deformability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in more detail below in conjunction with the accompanying drawings.

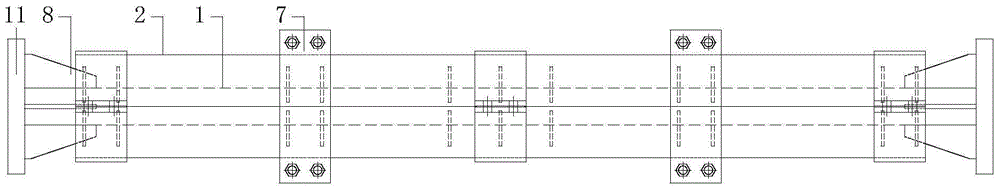

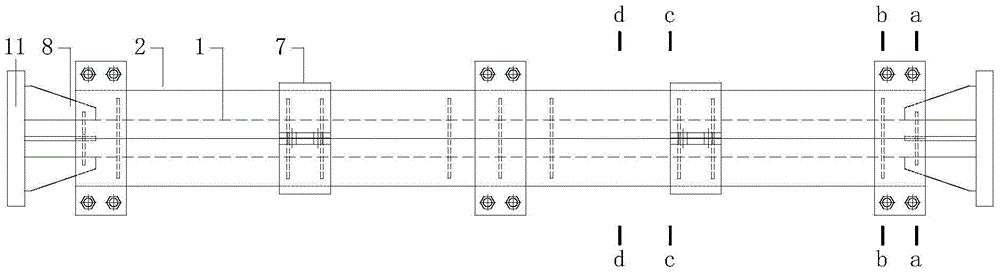

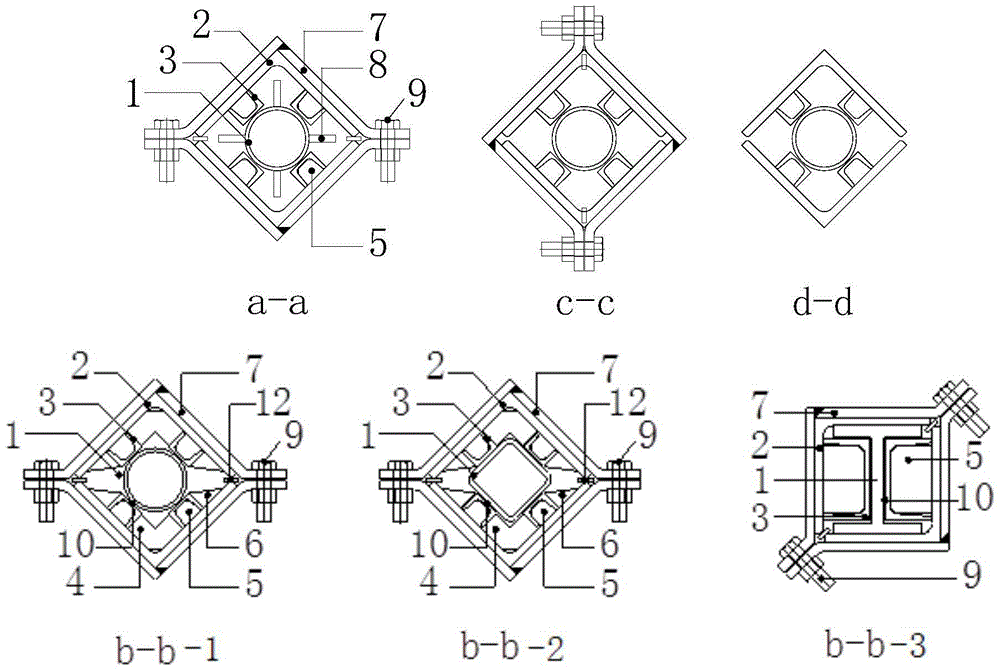

[0025] Such as figure 1 , figure 2 As shown in the figure, a metal buckling-constrained support of post-mounted casing includes an inner core profile 1, the inner core profile 1 is made of seamless square steel tube / round steel tube or H-shaped steel, and the two ends of the inner core profile 1 and the end plate 11 are Cutting and equal strength welding is adopted. In order to strengthen the connection between the inner core profile 1 and the end plates 11 at both ends, longitudinal stiffeners 8 are also welded between the inner core profile 1 and the end plates 11 to ensure that the inner core profile 1 and the end plates The tensile bearing capacity of the connecting nodes between 11 is greater than the tensile bearing capacity of the core material itself, the restraint sleeve is arranged outside the inner core profile 1, and anti-friction gaskets 10 are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com