Integrated fan processing system for vacuum cleaning

A processing system and vacuum cleaning technology, which is applied to the components of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc. Advanced problems, to achieve the effect of saving production costs and design costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below, in conjunction with the accompanying drawings, preferred embodiments of the present invention are given and described in detail, so that the functions and features of the present invention can be better understood.

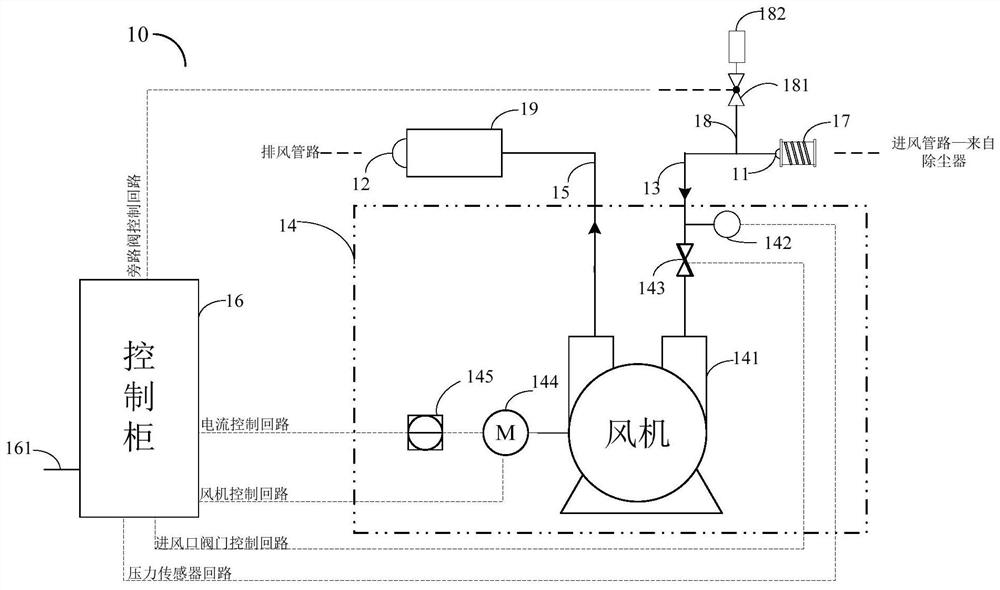

[0031] An integrated fan processing system for vacuum cleaning of the present invention includes at least one processing module 10, such as figure 1 As shown, the processing module 10 includes an air inlet 11 connected to the external air inlet pipeline, an air outlet 12 connected to the external exhaust pipeline, a fan unit 14, and a control cabinet 16, wherein the dotted line indicates that the control cabinet is connected to each device and instrument. , Valve control loop.

[0032] Wherein, the air inlet 11 is connected with the fan unit 14 through the air inlet pipe 13, and an elastic connector 17 is arranged between the air inlet 11 and the external air inlet pipeline, so that the clean air filtered by the dust collector enters the air inlet 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com