Water-in-oil type cosmetic composition having enhanced sustainability and providing alleviated sense of dryness

A water-in-oil type, cosmetic technology, applied in the direction of cosmetics, cosmetics, cosmetic preparations, etc., can solve problems such as decreased compatibility, achieve a good feeling of use, good skin moisturizing power and moisture retention, and remove makeup. slow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

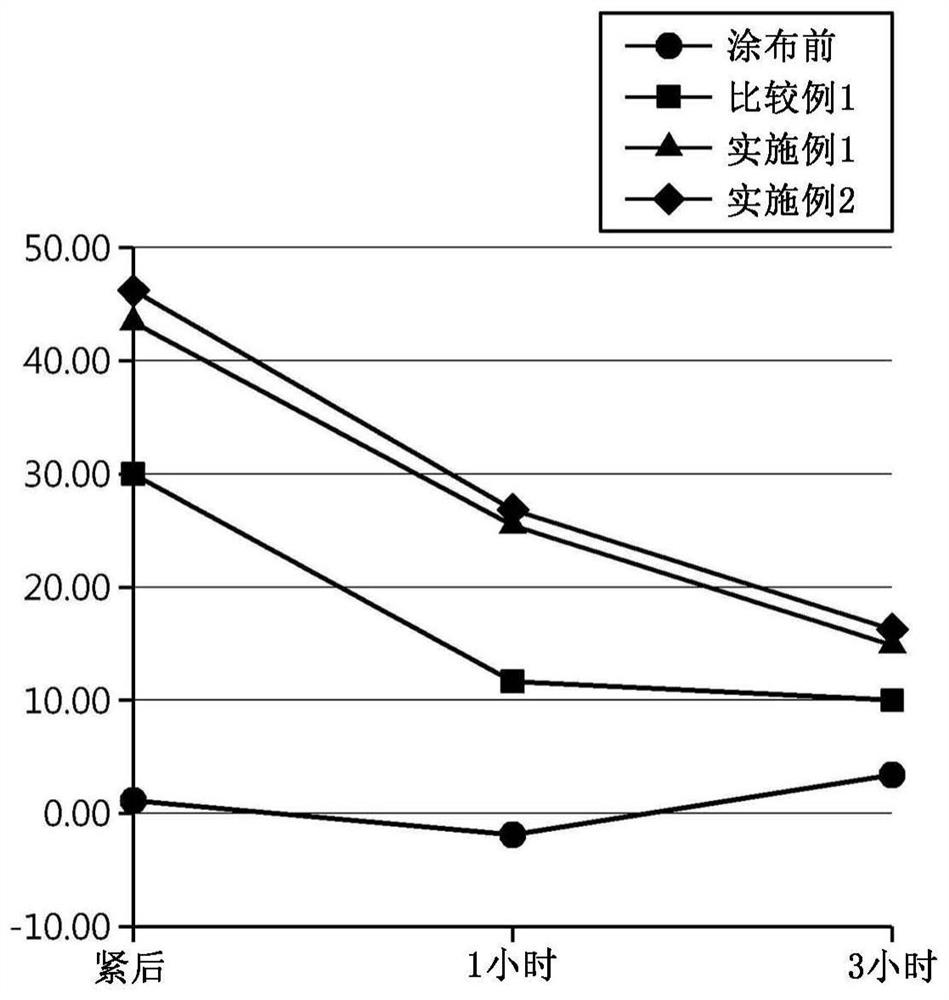

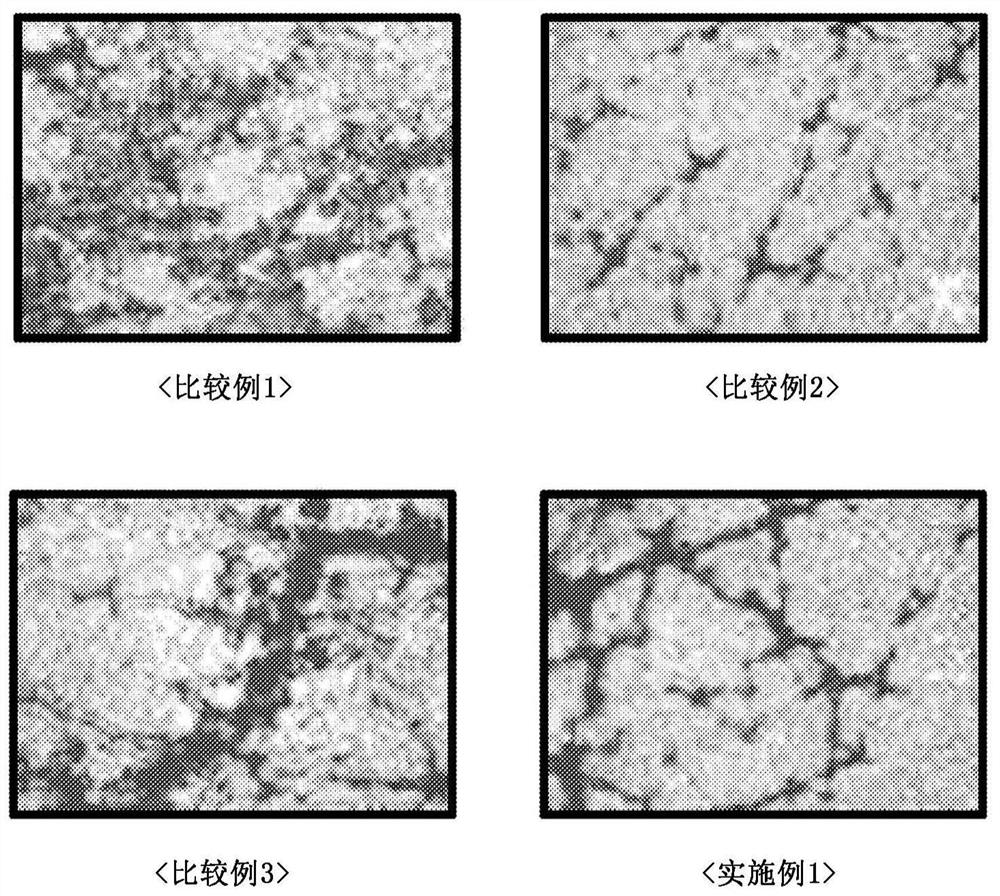

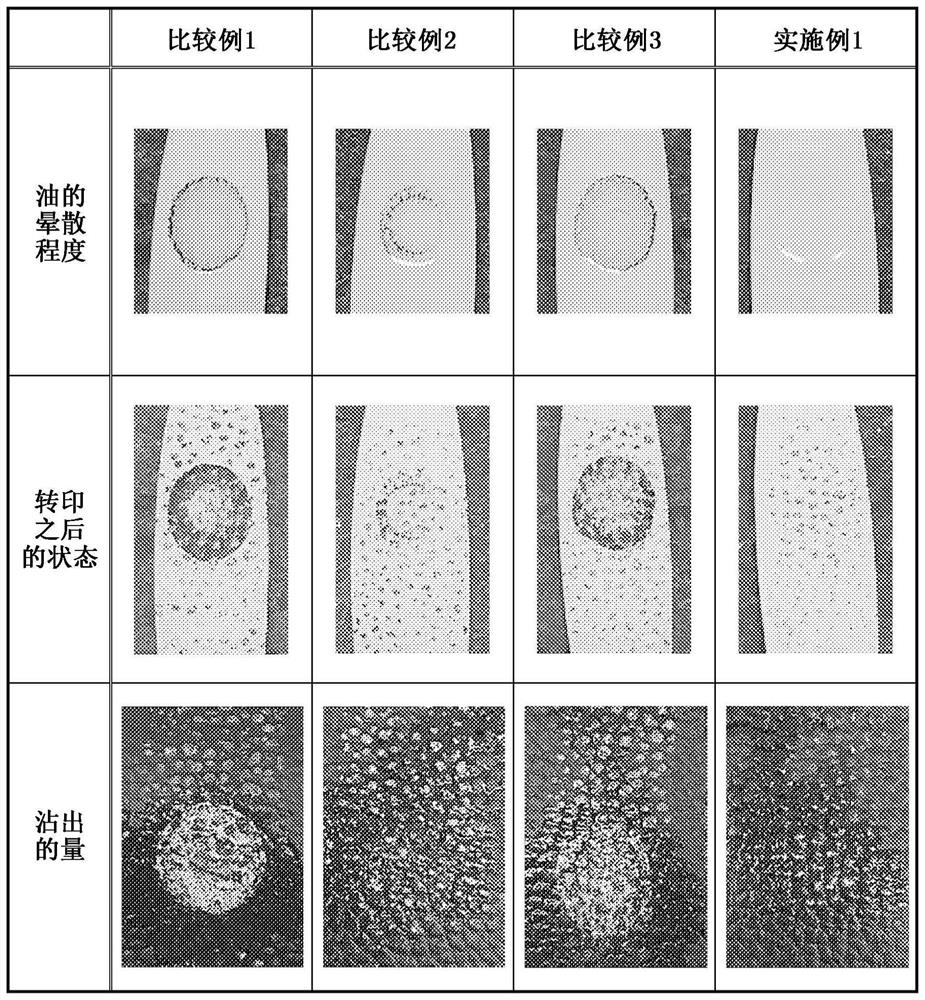

[0051] [Experimental Example 1] Cosmetic formulation for water-in-oil cosmetics including water-soluble and oil-soluble film-forming agents

[0052] In order to confirm the durability and dryness improvement of the water-in-oil type cosmetic composition containing a water-soluble and an oil-soluble film forming agent, it manufactured the following dosage form and performed an experiment.

[0053] Based on the components and contents (% by weight) described in Table 1, a water-in-oil cosmetic cosmetic was produced by the following production method.

[0054]

[0055] 1) Mix the oil phase components and disperse after heating to 80 degrees (°C).

[0056] 2) The colorant components are mixed and stirred in the above 1).

[0057] 3) In another water phase tank, slowly heat the water phase components to 80 degrees (° C.) to completely dissolve them.

[0058] 4) Slowly add the water phase component of the above 3) to the oil phase component of the above 1) and emulsify with a hi...

experiment example 2

[0087] [Experimental Example 2] Cosmetic components for water-in-oil type makeup with respect to each content of water-soluble film forming agent

[0088] 【Table 4】

[0089]

[0090] The production method was the same as that described in Experimental Example 1 above, and the durability, stability and usability were confirmed.

[0091] Persistence was evaluated by the same method as in Experimental Example 1, and physical properties were compared with room temperature after storage at 45 degrees (° C.) for 2 weeks for stability. A sensory evaluation was performed on the feeling of use, and 20 female consumers in their 20s to 40s were selected as objects to evaluate the degree of moisturization they felt, and the scores were scored from 0 to 5 and the scores were averaged.

[0092] 1) Stability evaluation criteria: O: Stable, △: Normal, X: Separation

[0093] 2) Moisturizing evaluation criteria: 1: Very bad, 2: Not good, 3: Fair, 4: Good, 5: Very good

[0094] 【table 5】 ...

experiment example 3

[0097] [Experimental Example 3] Cosmetic formulation for water-in-oil type makeup including other types of oil-soluble film-forming agents

[0098] Persistence was additionally evaluated with trimethylsiloxysilicate included in the oil phase.

[0099] A water-in-oil type cosmetic composition containing a film-forming agent in both the oil phase and the water phase was produced using the components shown in Table 6 below.

[0100] 【Table 6】

[0101]

[0102]

[0103] The test was carried out in the same manner as the above-mentioned durability test method, and the results are shown in Table 7 below.

[0104] 【Table 7】

[0105] Comparative example 5 Example 4 value 2469 2015

[0106] As shown in the above results, it was confirmed from numerical values that in Example 4, there was less collapse due to artificial sebum than in Comparative Example 5.

[0107] Therefore, when another type of oil-soluble film-forming agent was applied, the staying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com