Composition for resident facial masks

A composition and mask technology, applied in the directions of skin care preparations, cosmetics, cosmetic preparations, etc., can solve the problems of keratin damage, inability to resist adhesion pollution, inability to isolate makeup and anti-adhesion pollutants, etc., and achieve good comfort. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

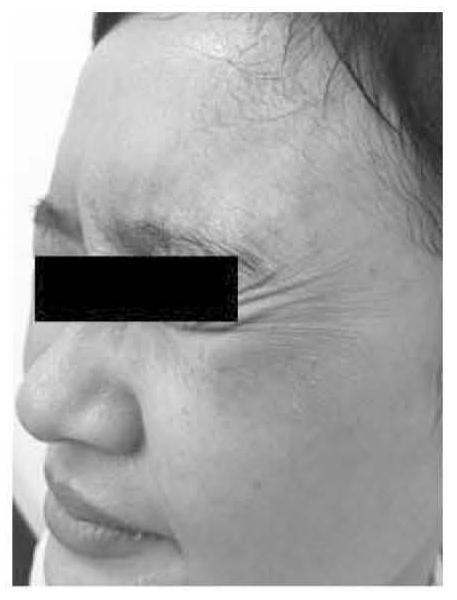

Image

Examples

Embodiment 1

[0068] In Example 1, 0.3 weight percent of acrylic acid (ester) / isodecanoic acid vinyl ester crosslinked polymer (C-1), 0.1 weight percent of acrylic acid / alkylacrylic acid crosslinked polymer with 10 to 30 carbons (C-2), 5% by weight of dipropylene glycol (D-1), 0.02% by weight of citric acid (F1-2) and 70.3% by weight of water (E) are mixed and stirred to form a uniformly dispersed aqueous phase solution , then 3 weight percent of PEG / PPG / polybutylene glycol-8 / 5 / 3 glycerin (B) (trade name: S-753, manufactured by NOF Corporation (WILBRIDE)), 2 weight percent of nicotine Amide (G1-1), 2 weight percent tranexamic acid (G1-2), 1 weight percent bisabolol and ginger root extract (G3-1 and G3-2), 0.18 weight percent arginine ( F1-1) and 1% by weight of hydrogenated ethylhexyl olive oil / hydrogenated olive oil unsaponifiable matter (F2-1) are added to the aforementioned aqueous phase solution in stirring and uniformly mixed. On the other hand, 5% by weight of ethanol (F5) and 0.1% b...

Embodiment 2 to Embodiment 7 and comparative example 1 to comparative example 5

[0070] Example 2 to Example 7 and Comparative Example 1 to Comparative Example 5 were all prepared in the same way as Example 1. The difference is that the amount of polyurethane-35 (A-1) used in Example 2 to Example 4 and Comparative Example 1 to Comparative Example 2 is different from that of Example 1. The usage amount of the polyurethane-35 (A-1) of embodiment 5 to embodiment 6 and comparative example 4 and the usage amount of PEG / PPG / polybutylene glycol-8 / 5 / 3 glycerin (B) and embodiment 1 different. The usage amount of the polyurethane-35 (A-1) of embodiment 7 is different from embodiment 1, and replaces acrylic acid (ester) with hydroxyethyl acrylate / sodium acryloyl dimethyl taurate copolymer (C-4) ) / vinyl isodecanoate crosspolymer (C-1) and acrylic acid / alkacrylic acid crosspolymer with 10 to 30 carbons (C-2). The consumption of polyurethane-35 (A-1) of comparative example 3, the consumption of PEG / PPG / polybutylene glycol-8 / 5 / 3 glycerin (B) and the consumption of dip...

Embodiment 8

[0072] Example 8 was prepared in the same manner as Example 1. The difference is that the amount of polyurethane-35 (A-1) in Example 8 is different from Example 1, and glycerin (D-2), caprylic / capric triglyceride (F3-1), methacrylic acid Methyl Ester Crosspolymer (C-3), Retinol (G2-1), Hydrogenated Lecithin (F2-2), Cholesterol (F3-2), Butylated Hydroxytoluene (G2-2), Tocopheryl Acetate Esters (G2-4), Mung Bean Seed Extract (G3-3), Butylated Hydroxyanisole (G2-3) and Oat Meal Extract (G3-4). The concrete conditions about embodiment 8 are as shown in table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com