Systems and methods for underground pipe installation

A technology for pipelines and removal systems, applied in pipeline laying and maintenance, drilling equipment and methods, drilling pipes, etc., can solve problems such as excess energy, and achieve the effect of overcoming surface friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

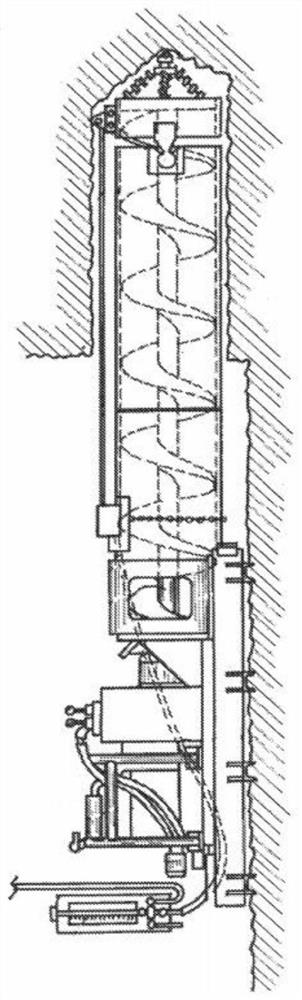

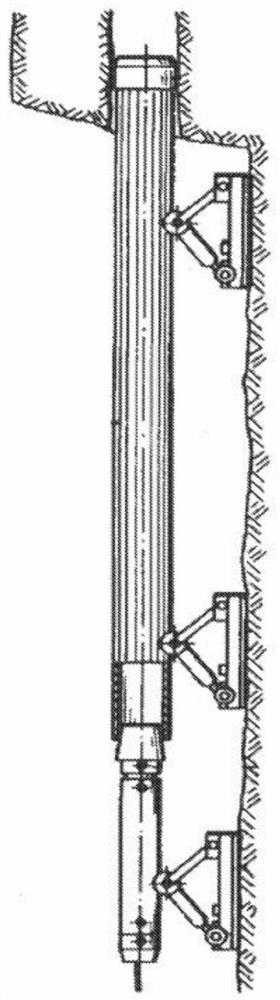

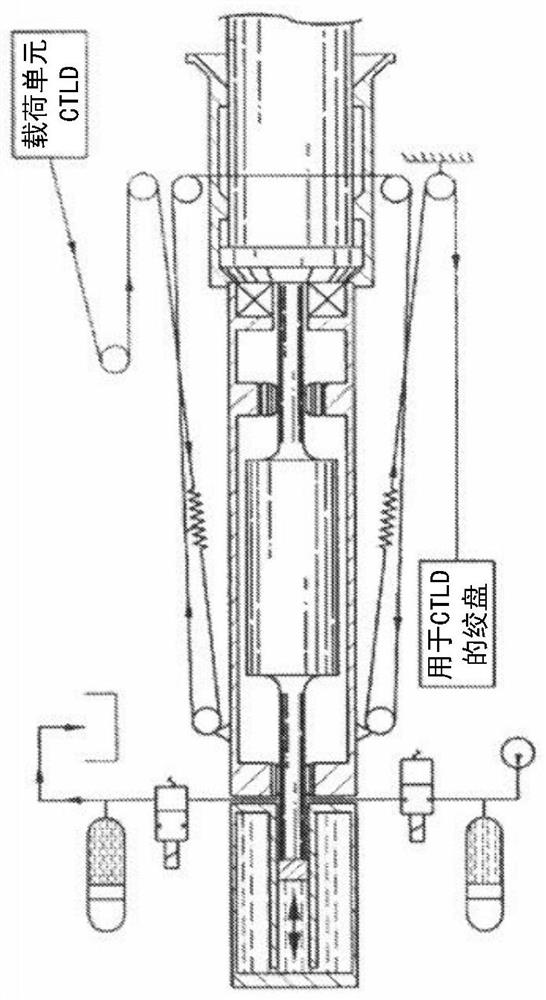

[0043] Such as Figure 4AAs shown, the hammer 10 is used to generate a periodic force (eg, a series of impact force) to the Riel-mounted main top feed frame 12. The hammer 10 can be impacted by an air hammer or other high-frequency drive device on the main top feed frame 12 using any suitable assembly device (not shown). The hammer 10 can be a type of Hammerhead Trenchless Equipment manufactured by a model 12- (300) -ar. Other models of hammers can also be used. The top frame is assisted by a set of hydraulic jacks 14, which increases hydraulic thrust to the main top into the frame 12. The main top feed frame 12 has a surface for contacting the sleeve 16 and transmits impact and hydraulic pressure to the sleeve 16. The casing portion 16 can be replaced by any product tube that can be resistant and transmitted from the impact force generated by the hammer 10. The primary top into the frame 12 is coupled and sliding over the modular main track 18 assembled to achieve the desired stro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com