V-ribbed belt and its use

A V-ribbed belt and vinyl technology, applied in other household appliances, belts, applications, etc., can solve the problems of lowering, not suitable for high-load transmission, etc., and achieve the goal of improving durability, reducing torque loss, and improving noise resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

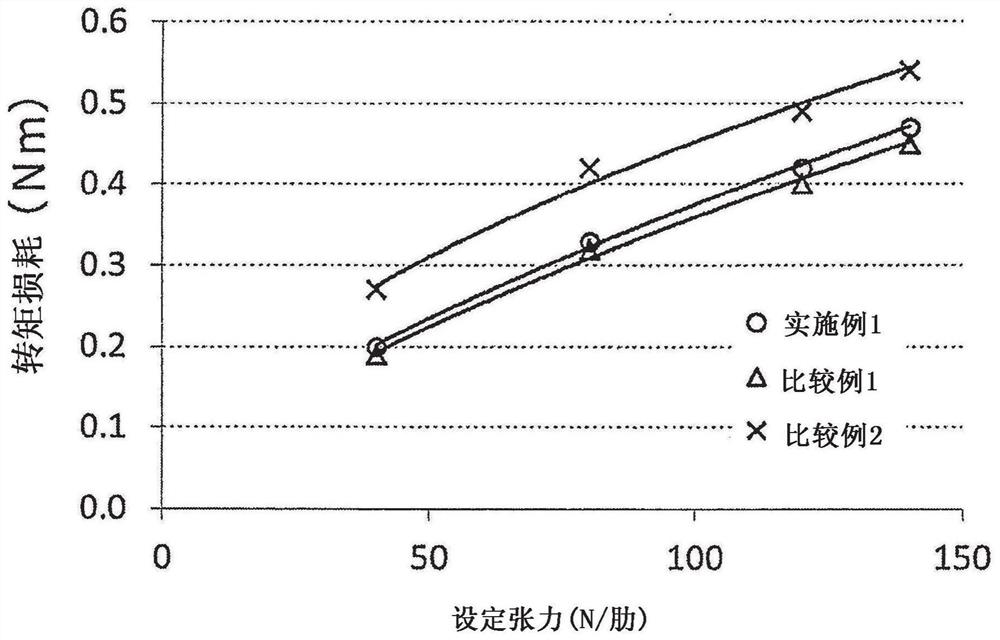

Embodiment 1~5 and comparative example 2~4

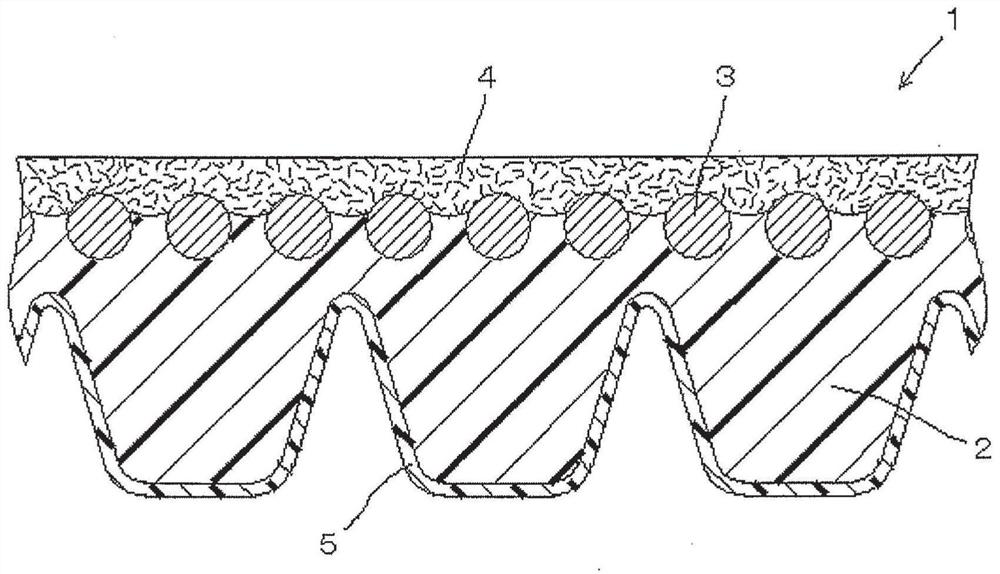

[0139] (Preparation of V-ribbed belt)

[0140] Using a cylindrical inner mold with a flexible sheath attached to the outer peripheral surface, an unvulcanized stretch layer sheet is wound around the flexible sheath on the outer peripheral surface, and the core wire forming the core is wound helically on the sheet (Twisted cord), and further wound an unvulcanized sheet for a compression rubber layer and a knitted fabric made of the rubber composition shown in Table 3 to produce a laminate. The inner mold wound with the cylindrical laminate is concentrically placed in the cylindrical outer mold with a plurality of rib molds engraved on the inner peripheral surface, and the above-mentioned flexible sheath is expanded to press the laminate into the rib mold. In, vulcanization is carried out at 180°C. Then, pull out the inner mold from the outer mold, release the vulcanized rubber sleeve with multiple ribs from the outer mold, use a cutter to cut the vulcanized rubber sleeve into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com