Warping pressing device and method used in strip steel rough rolling process

A rolling process, warping technology, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., to achieve the effect of reducing scrap steel and fault shutdown, and preventing fault expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

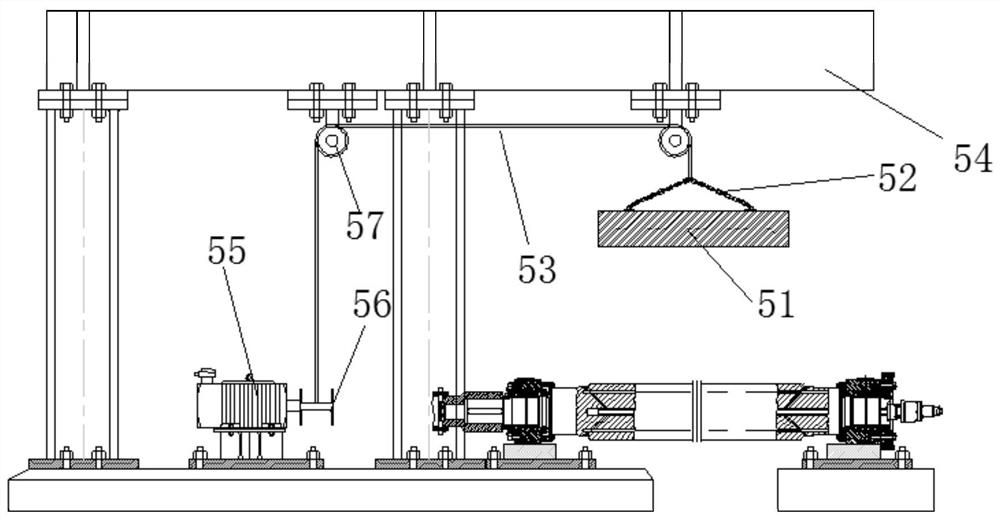

Examples

Embodiment

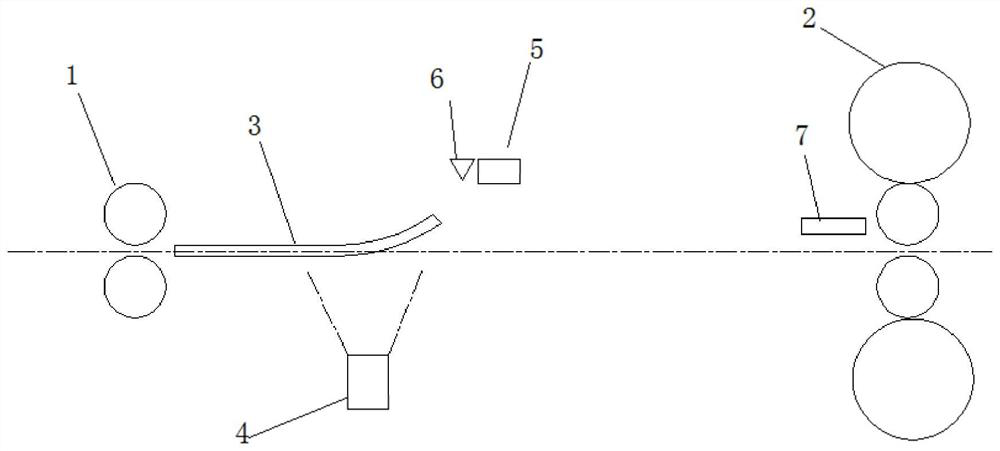

[0063] The distance between the centerlines of the first rough rolling stand 1 and the second stand 2 is 112 meters. The length of the first stand after the unrolled pass is about 25 meters, and the length of the second stand after the last even pass is about 50 meters. The strip steel bumps the warping head leveling device, therefore, the warping head leveling device is installed at a position 65 meters away from the second rack.

[0064] A method for warping the head in the rough rolling process of strip steel, comprising the following steps:

[0065] S1. The strip steel comes out of the first rack; the buckle head detection device detects that the height of the buckle head is 320mm; L1 confirms that it is the last pass of the first rack, and the height of the buckle head exceeds the entrance equipment height of the second rack by 300mm; L1 is the equipment operation control computer system.

[0066] S2, L1 stop the unit in front of the first rack for steel extraction and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com