Concrete premixing device and concrete premixing production process

A technology of ready-mixed concrete and concrete, which is applied in the field of concrete, and can solve problems such as easy to be stained with dust, affect concrete forming efficiency and forming quality, and achieve the effect of improving the quality of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

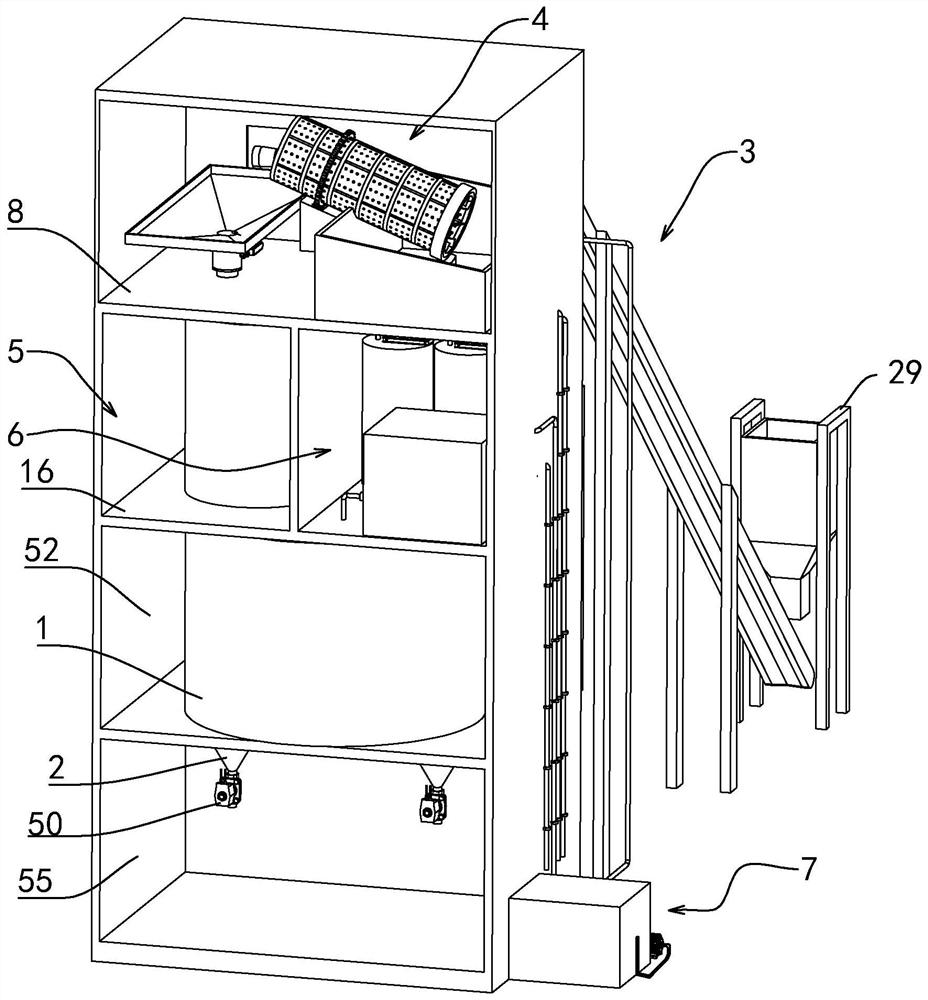

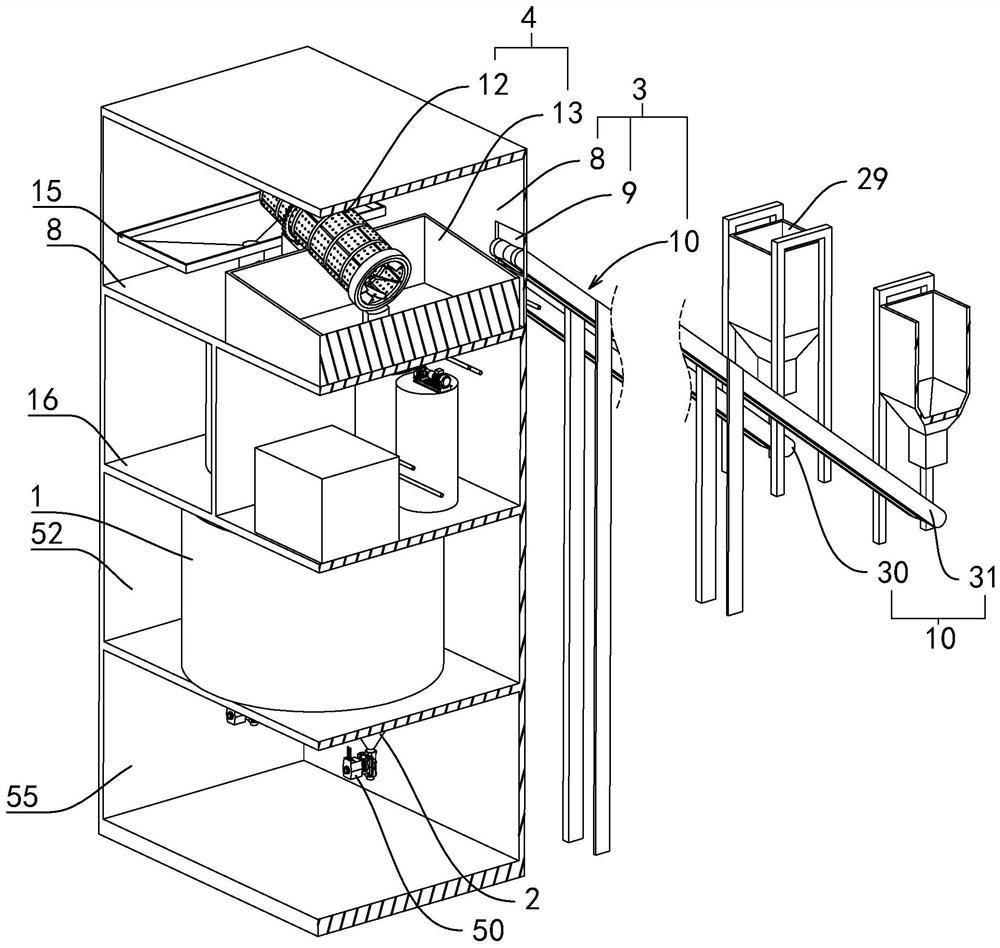

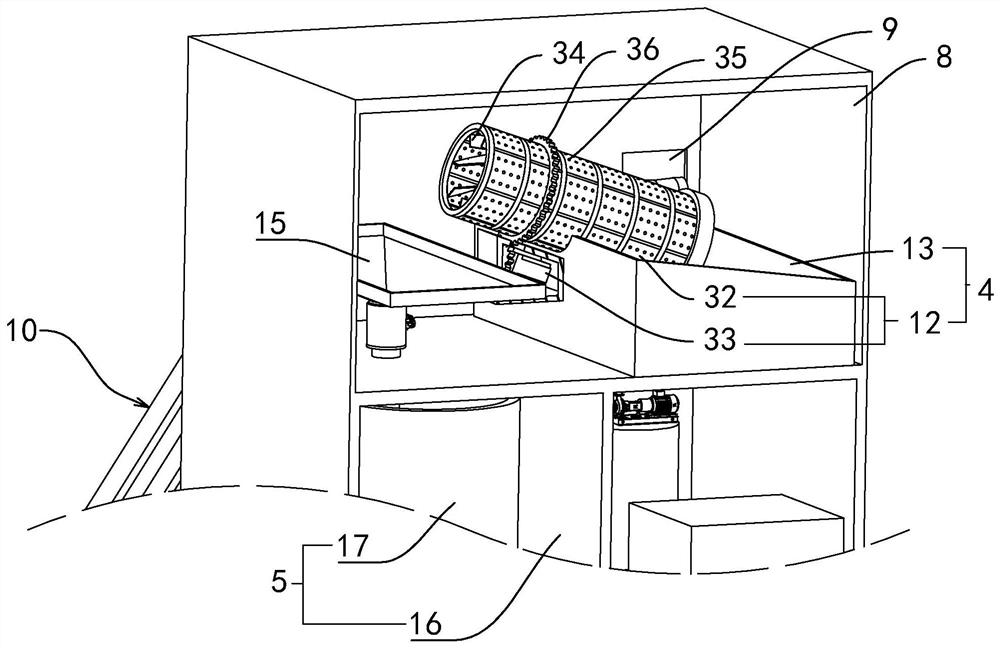

[0049] refer to figure 1 , is a kind of ready-mixed concrete device disclosed by the present invention, comprising a mixing tank 1, the bottom of the mixing tank 1 is provided with a general discharge port 2, and a sandstone feeding mechanism 3, a cleaning mechanism 4, a mixing mechanism 5, an auxiliary Mechanism and clean water circulation mechanism 7, send sand and stones through the sand feeding mechanism 3, send materials such as stones and sand to the cleaning mechanism 4 for cleaning, reduce the dust and soil contaminated on the stones, and improve the cleaning of concrete materials As a result, the stones will be sent to the mixing mechanism 5 for preliminary mixing after cleaning, and the stones mixed with the mixing mechanism 5 and the bottom of the sand box will be sent to the mixing tank 1 at the bottom, and the auxiliary material mechanism 6 will also be sent to the mixing tank 1 Auxiliary materials such as cement, at the same time, the clear water circulation mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com