Layered stir concrete continuous feeding system

A feeding system and mixing system technology, which is applied in the field of layered mixing concrete continuous feeding system, can solve the problems of inability to adapt to continuous concrete spraying on site, uneven mixing, low efficiency, etc., and improve construction continuity and work efficiency. Efficiency, improvement of concrete quality, and improvement of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

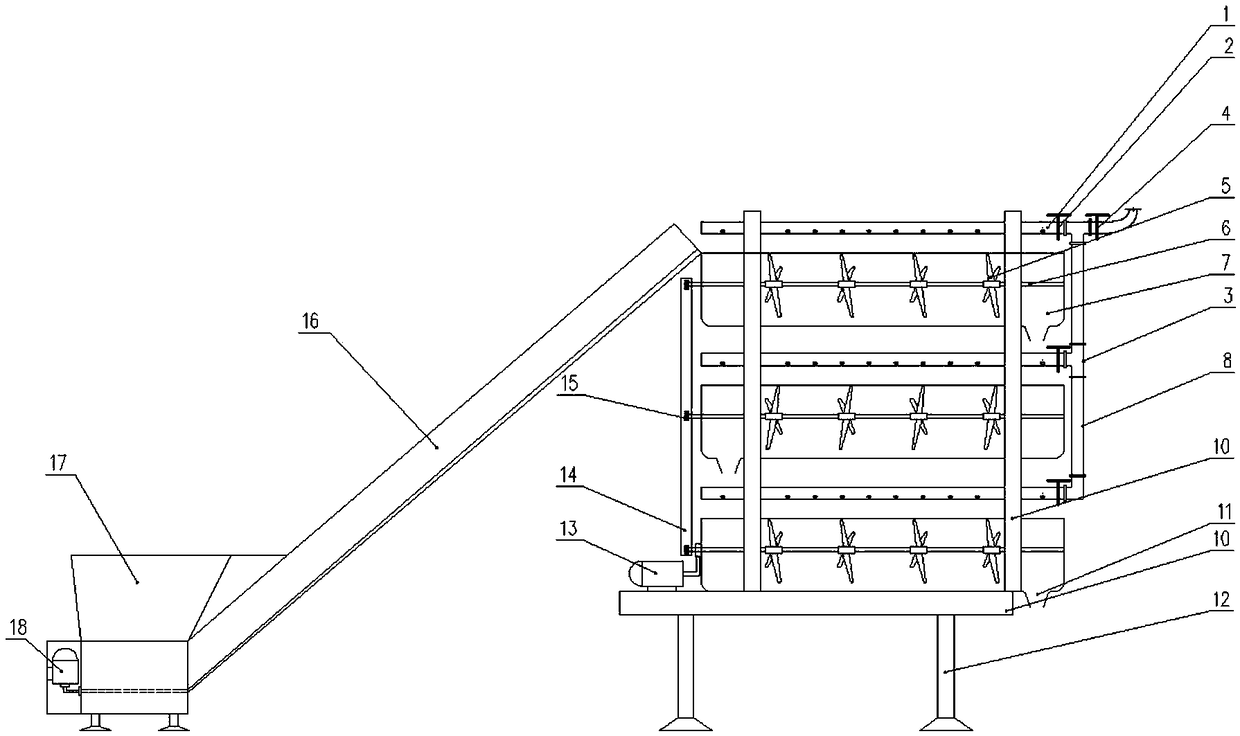

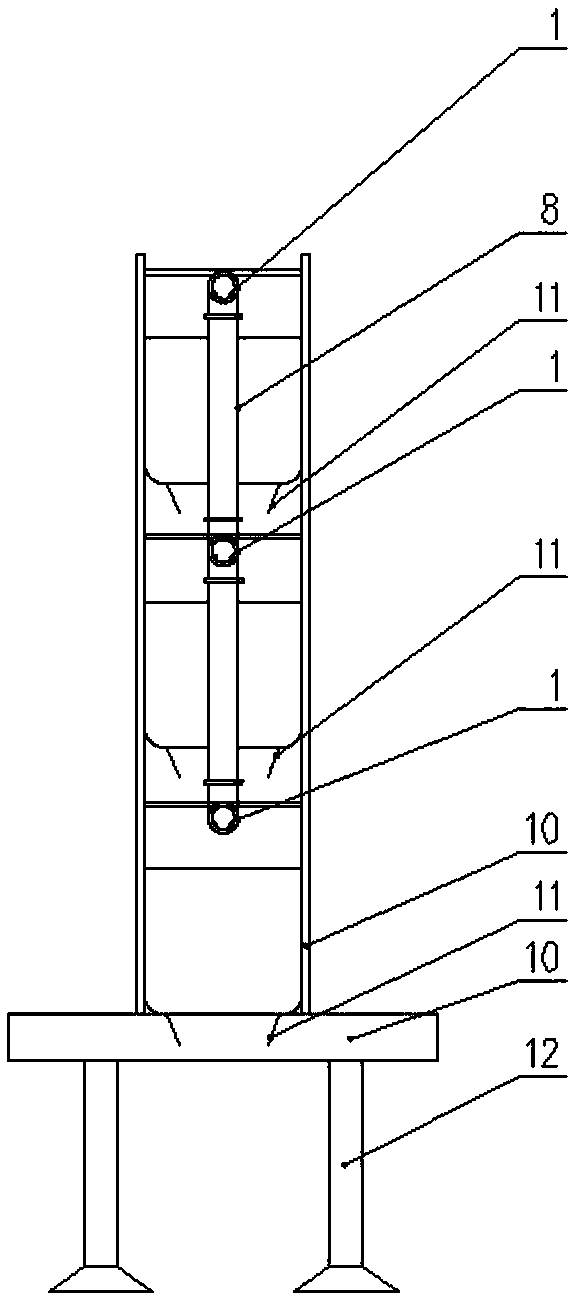

[0016] The present invention will be further explained below in conjunction with the accompanying drawings.

[0017] A layered mixing concrete continuous feeding system, such as figure 1 , figure 2 As shown, it consists of a stirring system and a continuous feeding system. The mixing system includes several layers of vertically distributed layered mixing mechanisms. The layered mixing mechanism includes a long strip-shaped mixing tank fixed on the frame, and the frame is supported by legs arranged at the bottom. There is a stirring shaft in the stirring tank, a stirring blade is arranged on the stirring shaft, and a driving mechanism for driving the stirring shaft to rotate is arranged on the frame. The driving mechanism includes a power motor or an electric motor fixed on the frame, and gears for transmission, structures such as chains. The stirring shafts in the stirring tanks of each layer are composed of a first stirring shaft arranged horizontally in the middle, a sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com