Paperboard preprinting production line

A production line and pre-printing technology, applied in printing, printing machines, printing devices, etc., can solve the problems of ink stickiness, blurred printed products, excessive ink, etc., and achieve cleanliness, reduce vibration, and uniform ink distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

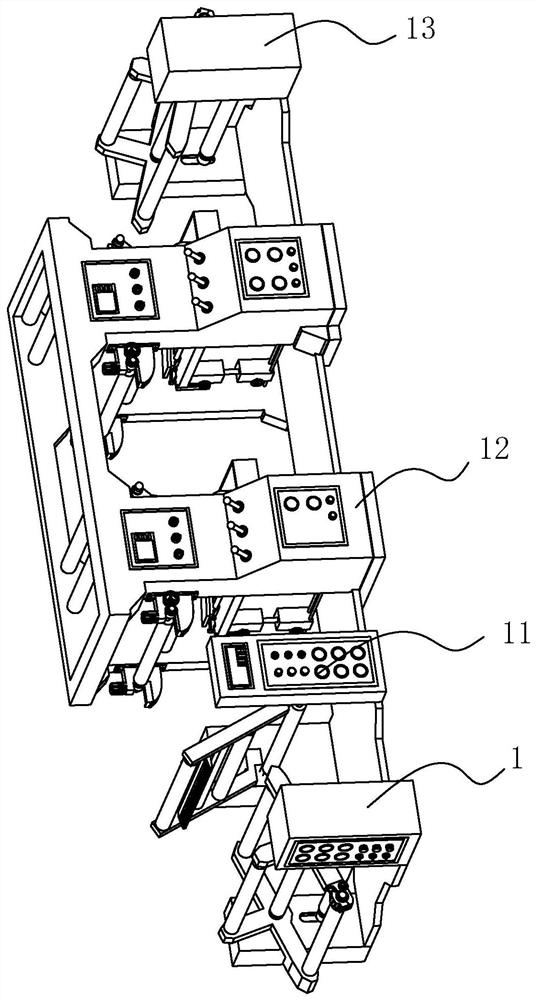

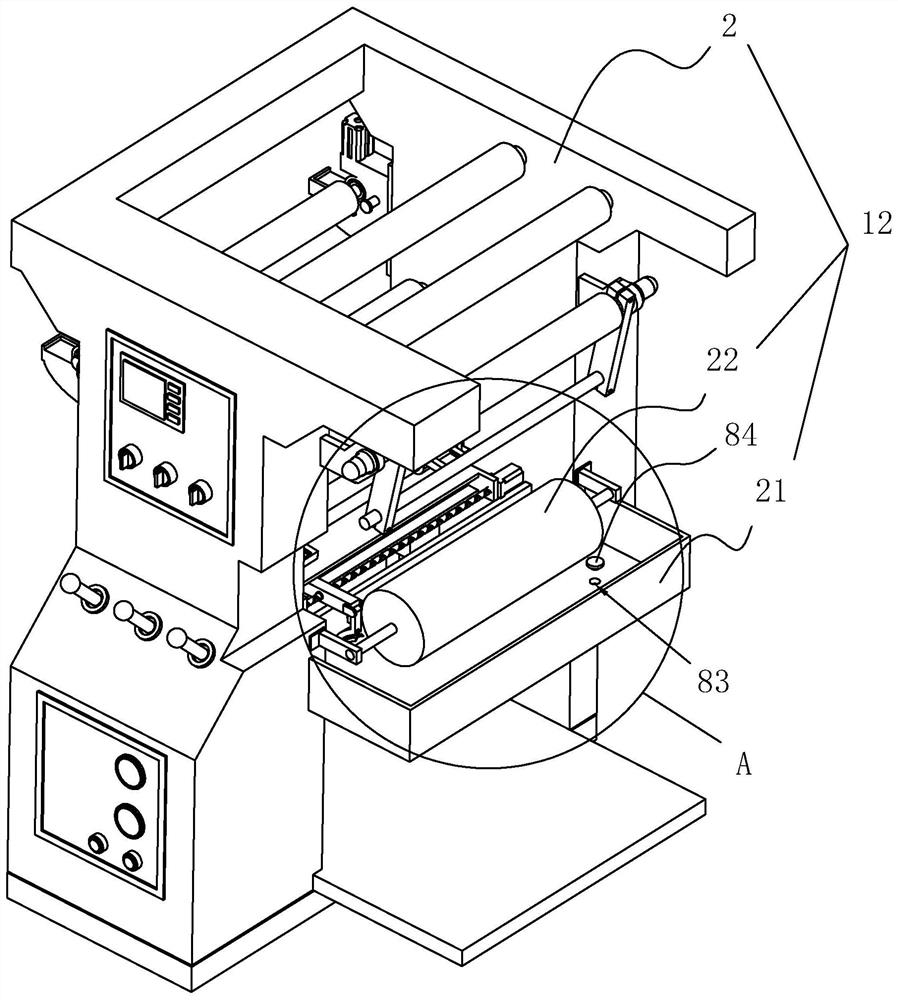

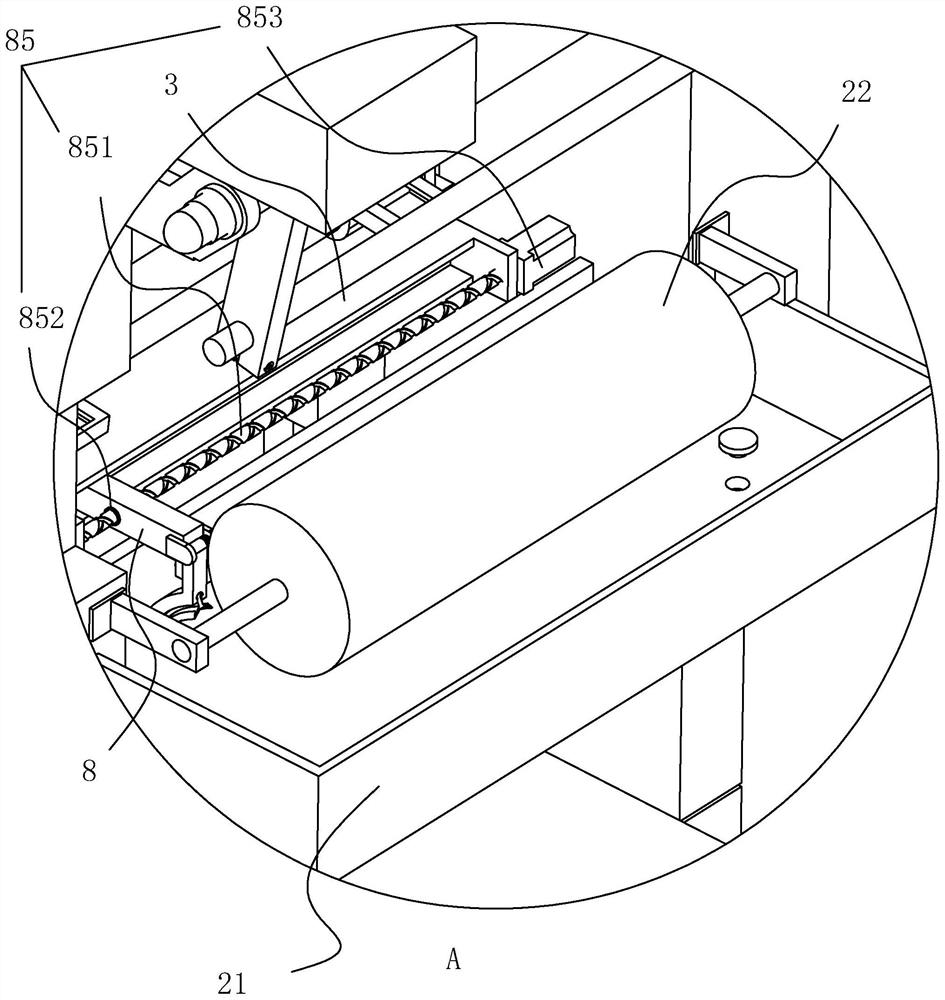

[0042] refer to figure 1 , 2 , is a cardboard pre-printing production line disclosed in the present invention, including an unwinding device 1, a tensioning device 11, a printing device 12 and a winding device 13 arranged in sequence, wherein the printing device 12 is continuously arranged in multiple groups for printing and dyeing different pigments and ink. The unwinding device 1 and the winding device 13 are all four-station winding and unwinding machines, which are respectively located at the head and tail of the production line. The tension device 11 is a tensioner. The printing device 12 includes a frame 2 , an ink cartridge 21 and an ink transfer roller 22 . The ink cartridge 21 is located on the side of the frame 2 away from the tension device 11, and is fixedly installed with the frame 2 bolts. The drain pipe, the other end of the drain pipe is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com