Garnet-based fluorescent material and preparation method thereof

A fluorescent material, garnet-based technology, applied in the field of fluorescent materials, can solve the problems of complex preparation methods, low yield, poor stability, etc., and achieve the effects of reducing energy consumption, improving transparency, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

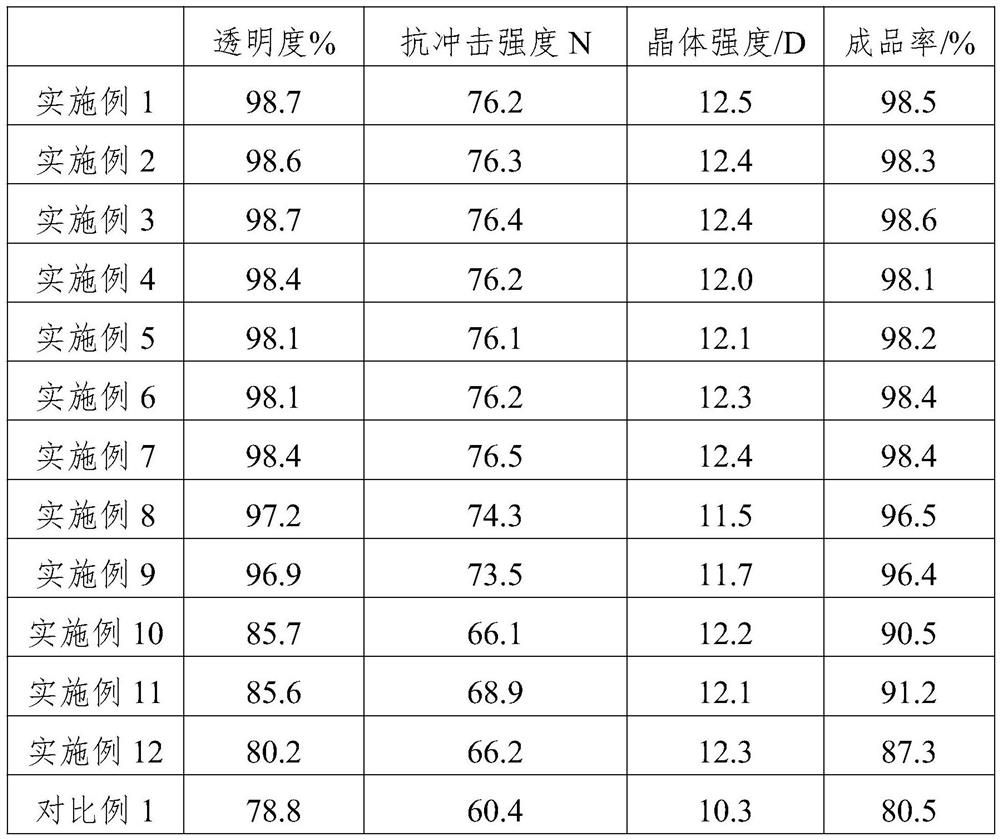

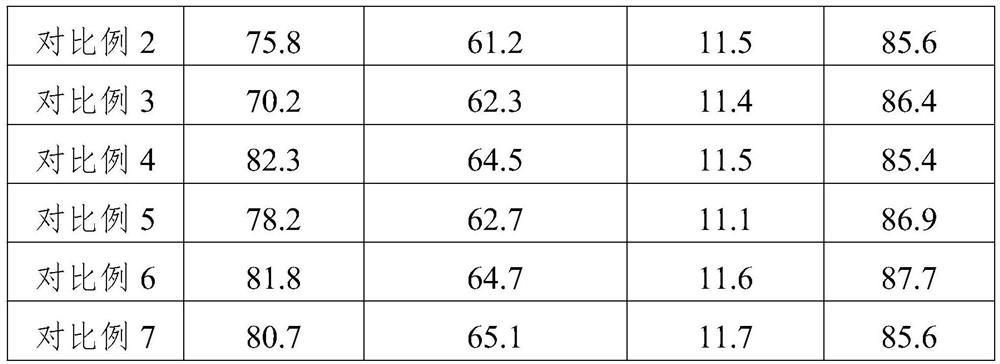

Examples

Embodiment 1

[0032] A garnet-based fluorescent material has a composition of the following chemical formula:

[0033] Ce 3 Al 4.8 Ga 0.2 o 12 :Tb 3

[0034] A method for preparing a garnet-based fluorescent material, comprising the following steps:.

[0035] 1), weighing raw materials: weighing 7 parts of Ce-containing compound, 9 parts of Al 2 o 3 , 0.5 parts of Ga-containing chemicals, 0.6 parts of Tb-containing compounds, 3 parts of MgO 2 , and stir and mix evenly to obtain a mixture;

[0036] 2) High-temperature calcination: put the mixture into the calcination furnace, and calcine at 850°C for 3 hours;

[0037] 3) Raw material washing: wash the raw material calcined in step 2 with deionized water, and dry at 105° C. for 5.5 hours using a dryer;

[0038] 4) Roasting of raw materials: Add the washed and dried raw materials into a roasting furnace, and roast them at 1550°C for 2 hours. After the roasting is completed, stand still in the roasting furnace for 0.75 hours. During t...

Embodiment 2

[0041] A garnet-based fluorescent material has a composition of the following chemical formula:

[0042] Ce 3 Al 4.8 Ga 0.2 o 12 : Eu 3

[0043] A method for preparing a garnet-based fluorescent material, comprising the following steps:.

[0044] 1), weighing raw materials: weighing 6 parts of Ce-containing compound, 7 parts of Al 2 o 3, 0.2 parts of Ga-containing chemicals, 0.5 parts of Eu-containing compounds, 2 parts of CaO, and stirred and mixed evenly to obtain a mixture;

[0045] 2) High-temperature calcination: add the mixture into the calcination furnace, and calcine at 800°C for 2 hours;

[0046] 3) Raw material washing: wash the raw material calcined in step 2 with deionized water, and dry at 100° C. for 5 hours using a dryer;

[0047] 4) Roasting of raw materials: Add the washed and dried raw materials into a roasting furnace, and roast at 1500°C for 1.5 hours. After the roasting is completed, stand still in the roasting furnace for 0.5 hours. During this p...

Embodiment 3

[0050] A garnet-based fluorescent material has a composition of the following chemical formula:

[0051] Ce 3 al 4.8 Ga 0.2 o 12 : Dy 3

[0052] A method for preparing a garnet-based fluorescent material, comprising the following steps:.

[0053] 1), weighing raw materials: weighing 8 parts of Ce-containing compound, 11 parts of Al 2 o 3 , 0.9 parts of Ga-containing chemicals, 0.8 parts of Dy-containing compounds, 5 parts of MgO 2 , and stir and mix evenly to obtain a mixture;

[0054] 2) High-temperature calcination: add the mixture into the calcination furnace, and calcine at 900°C for 4 hours;

[0055] 3) Raw material washing: wash the raw material calcined in step 2 with deionized water, and dry at 110° C. for 6 hours using a dryer;

[0056] 4) Roasting of raw materials: Add the washed and dried raw materials into the roasting furnace, and roast at 1600 ° C for 2.5 hours. After the roasting is completed, stand still in the roasting furnace for 1 hour, and nitroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com