Beer taste harmonization method and beer obtained therefrom

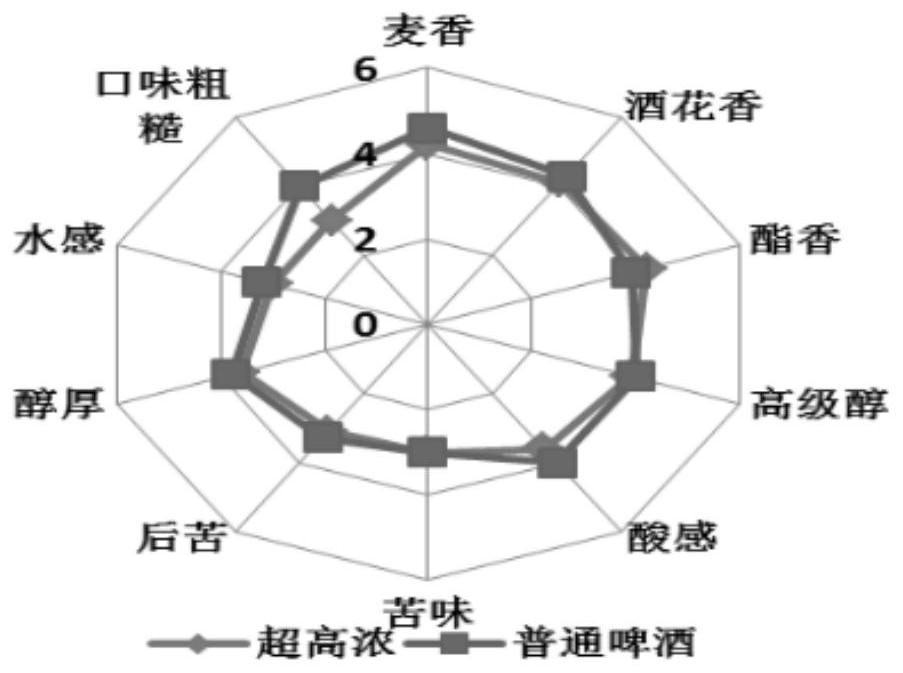

A coordinating method and taste technology, applied in the direction of beer brewing, etc., can solve the problems of uncoordinated flavor, weak beer taste, poor infusion retention, etc., and achieve the effect of solving uncoordinated taste, soft and harmonious taste, and simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

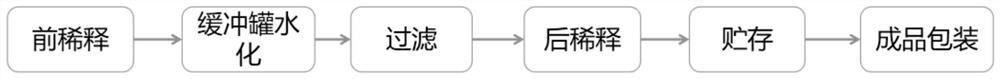

Method used

Image

Examples

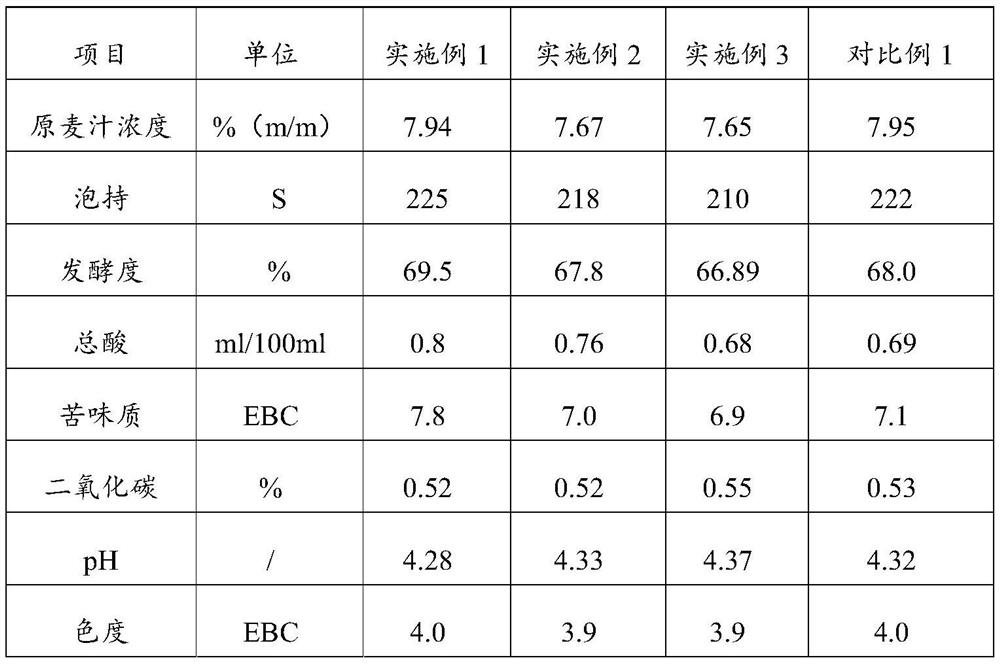

Embodiment 1

[0060] The present embodiment provides a kind of beer taste coordination method, and its specific method is as follows:

[0061] (1) Pre-dilution: 22 ° ultra-high-concentration liquor is pre-diluted with dilution water, and the dilution rate is 80%. The calcium ion content in the dilution water is 40ppm, the chloride ion content is 50ppm, and the sodium and potassium ion content is 25ppm. The oxygen content is 10ppb;

[0062] (2) Hydration of the buffer tank: After the pre-dilution is completed, enter the buffer tank for hydration, and the hydration time is 14 hours;

[0063] (3) Filtration: After the hydration of the buffer tank is completed, it enters the filtration step, and the turbidity of the filtered wine is 0.5EBC;

[0064] (4) post-dilution: use dilution water to carry out post-dilution to the wine liquor after filtering, and the dilution rate is 53%, and the post-dilution wine liquor;

[0065] (5) Storage: transfer the post-diluted wine into a sake tank, and store ...

Embodiment 2

[0068] The present embodiment provides a kind of beer taste coordination method, and its specific method is as follows:

[0069] (1) Pre-dilution: 18° ultra-high concentration liquor is pre-diluted with dilution water, and the dilution rate is 71%, wherein the content of calcium ions in the dilution water is 40ppm, the content of chloride ions is 50ppm, and the content of sodium and potassium ions is 25ppm. The oxygen content is 10ppb;

[0070] (2) Hydration of the buffer tank: After the pre-dilution is completed, enter the buffer tank for hydration, and the hydration time is 14 hours;

[0071] (3) Filtration: After the hydration of the buffer tank is completed, it enters the filtration step, and the turbidity of the filtered wine is 0.5EBC;

[0072] (4) post-dilution: use dilution water to carry out post-dilution to the wine liquor after filtering, and the dilution rate is 40%, and the post-dilution wine liquor;

[0073] (5) Storage: transfer the post-diluted wine into a sa...

Embodiment 3

[0076] The present embodiment provides a kind of beer taste coordination method, and its specific method is as follows:

[0077] (1) Pre-dilution: 20° ultra-high-concentration liquor is pre-diluted with dilution water, and the dilution rate is 82%, wherein the content of calcium ions in the dilution water is 40ppm, the content of chloride ions is 50ppm, and the content of sodium and potassium ions is 25ppm. The oxygen content is 10ppb;

[0078] (2) Hydration of the buffer tank: After the pre-dilution is completed, enter the buffer tank for hydration, and the hydration time is 14 hours;

[0079] (3) Filtration: After the hydration of the buffer tank is completed, it enters the filtration step, and the turbidity of the filtered wine is 0.5EBC;

[0080] (4) post-dilution: use dilution water to carry out post-dilution to the wine liquor after filtering, and the dilution rate is 47%, and the post-dilution wine liquor;

[0081] (5) Storage: transfer the post-diluted wine into a sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com