A low-temperature brewing process of beer with high malt aroma

A malt and aroma technology, applied in beer brewing, wort preparation, beer fermentation methods and other directions, can solve problems such as undisclosed beer high malt aroma, achieve pure and strong malt aroma, enhance core competitiveness, and taste soft and harmonious Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

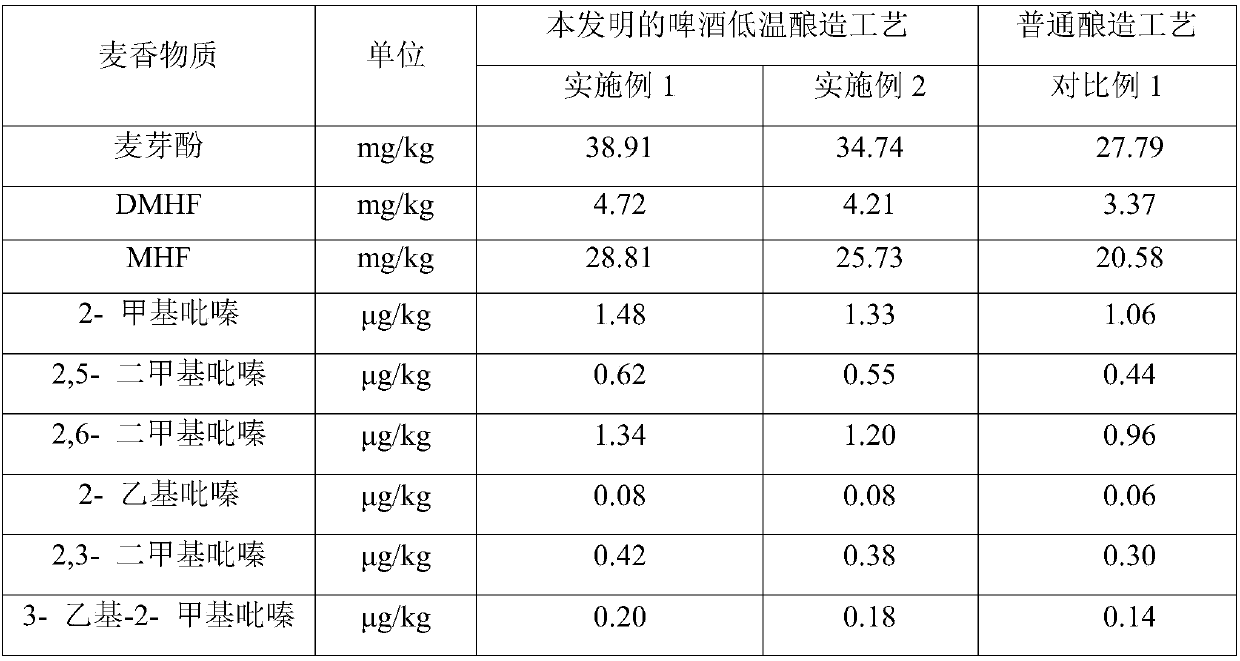

[0028] Example 1: Process for preparing high-malt aroma beer by adding malt and Australian malt

[0029] 1) Selection of raw materials: Common malts——additional malt and Australian malt are selected as brewing raw materials, and japonica rice is used as auxiliary material, of which 45% are added malt, 25% are Australian malt, and 30% are japonica rice.

[0030] 2) Wort preparation

[0031] ①Gelatification: After the rice is pulverized by a rice grinder, the mash is transferred into the gelatinization pot, and an appropriate amount of high-temperature-resistant α-amylase is added. Under the joint action of heat and amylase, the rice starch is decomposed into soluble oligosaccharides and dextrin, which is The saccharification process lays the foundation for obtaining a large amount of fermentable sugar and improving sugar extract.

[0032] ②Saccharification: The malt is crushed by a malt grinder, then transferred to mash and enters the mash pot, the pH value of the mash is adju...

Embodiment 2

[0040] Example 2: Process for preparing high-malt aroma beer using domestic malt

[0041] 1) Raw material selection: choose common domestic malt—Northwest malt as brewing raw material, and japonica rice as auxiliary material, of which Northwest malt accounts for 70%, and japonica rice accounts for 30%.

[0042] 2) Wort preparation

[0043] ①Gelatification: Rice decomposes starch into soluble oligosaccharides and dextrin under the action of high temperature-resistant α-amylase in the gelatinization pot under the environment of suitable temperature, pH and substrate concentration, which is the saccharification process. Lay the groundwork for obtaining large amounts of fermentable sugars and increasing sugar extract.

[0044] ②Saccharification: The crushed malt enters the mash pot, the pH of the mash is adjusted to 5.7, and the resting temperature of the protein is controlled at 50°C. After the rest of the protein, the gelatinized mash is pumped into the mash tun, mixed with th...

Embodiment 3

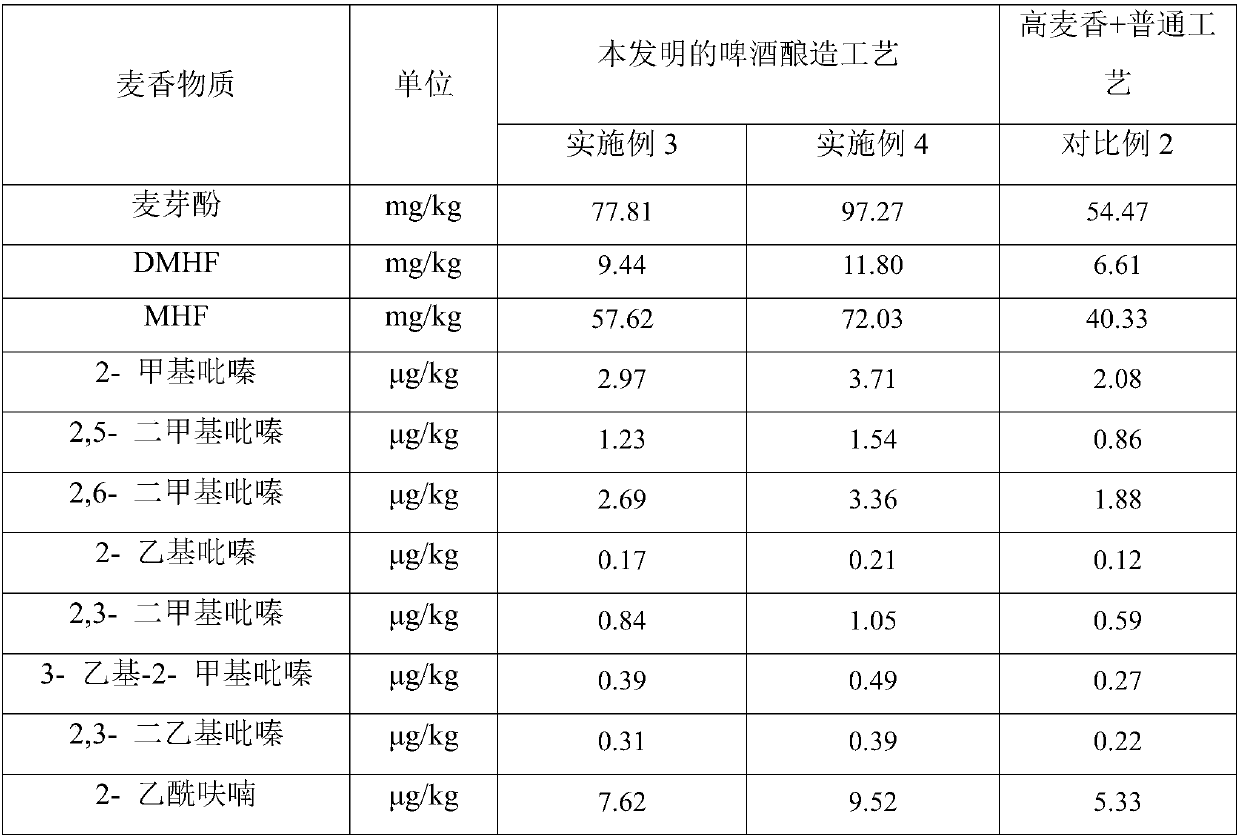

[0065] Example 3: Beer preparation process containing 4% high malt aroma malt

[0066] 1) Raw material selection: choose high-malt fragrant malt, added malt and Australian malt as brewing raw materials, and japonica rice as an auxiliary material, of which high-malt fragrant malt accounts for 4%, added malt accounts for 45%, Australian malt accounts for 21%, and japonica rice accounts for 30% %. (Wherein, high malt aroma malt is prepared by the preparation method of 201410052207.3 "A kind of malt preparation method with high malt aroma and beer thereof")

[0067] 2) Wort preparation

[0068] ①Gelatification: The crushed rice enters the gelatinization pot, and an appropriate amount of high-temperature-resistant α-amylase is added. Under the joint action of heat and amylase, the starch in the rice is decomposed into soluble oligosaccharides and dextrin, and a large amount is obtained for the saccharification process. Fermentable sugars and the basis for increasing sugar extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com