Large miter gate low-position top door and bottom pivot overhauling system and using method

A herringbone gate and bottom pivot technology, applied in ship locks, ship lifting devices, metal processing, etc., can solve the problems of uncontrollable construction period, many uncertain factors, and time constraints, and achieve safe and rapid removal and return, and rapid dismantling. And the effect of displacement and quick removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

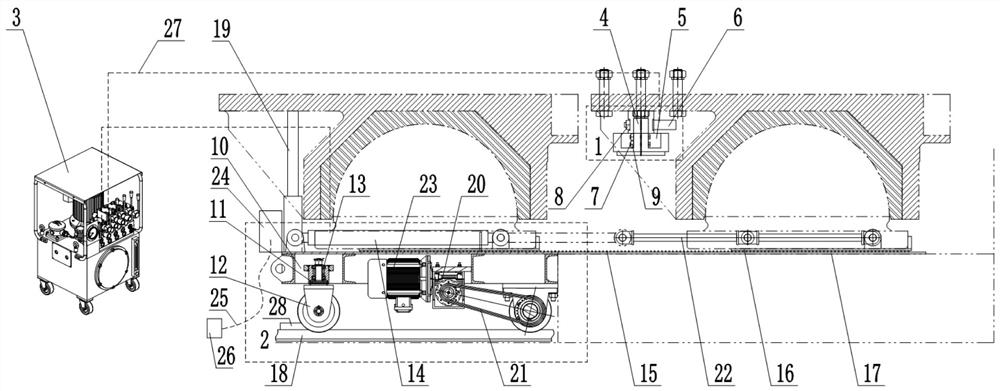

[0039] see figure 1 , a large-scale miter gate low top door bottom pivot maintenance system, which includes a bottom pivot hinge hole bolt removal tool 1 for removing the bottom pivot hinge hole bolt, the bottom pivot hinge hole bolt removal tool 1 is connected with A hydraulic pump station 3 for providing hydraulic power is connected; it includes a quick shift tooling 2 for the bottom pivot that has been removed, and the quick shift tool 2 for the bottom pivot is connected to the hydraulic pump station 3 . By adopting the maintenance system with the above-mentioned structure, it is possible to realize quick dismantling of bolts for hinged holes of the bottom pivot in a narrow space according to construction requirements. During the shifting process of the bottom pivot, the fast shift tooling of the bottom pivot moves forward along the track to ensure safe and fast moving out and return. The maintenance efficiency is improved, the maintenance period is shortened, the difficul...

Embodiment 2

[0049] The method for using the maintenance system of the low top door and bottom pivot of the large miter gate includes the following steps:

[0050] Step 1: Tighten the hexagonal bolts of the reaming hole; open the valve group 3 of the hydraulic pump station, supply oil to the tightening cylinder 6, and tighten the piston rod of the tightening cylinder 6 with the cylinder lock nut 8 to retract and tighten in place. pressure, close the valve group;

[0051] Step 2: Jack up and remove the hinged hole bolts; open the valve group 3 of the hydraulic pump station, and supply oil to the two sets of afterburner cylinders 4 at the same time, the piston rod of the afterburner cylinder rises, and it is attached to the bottom surface of the bottom pivot top cover to add force;

[0052] Step 3: The bottom pivot is in place; the bottom pivot is placed on the removal platform 16, and the hydraulic pump station 3 valve groups supply oil to the hydraulic cylinder 14, and the piston rod of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com